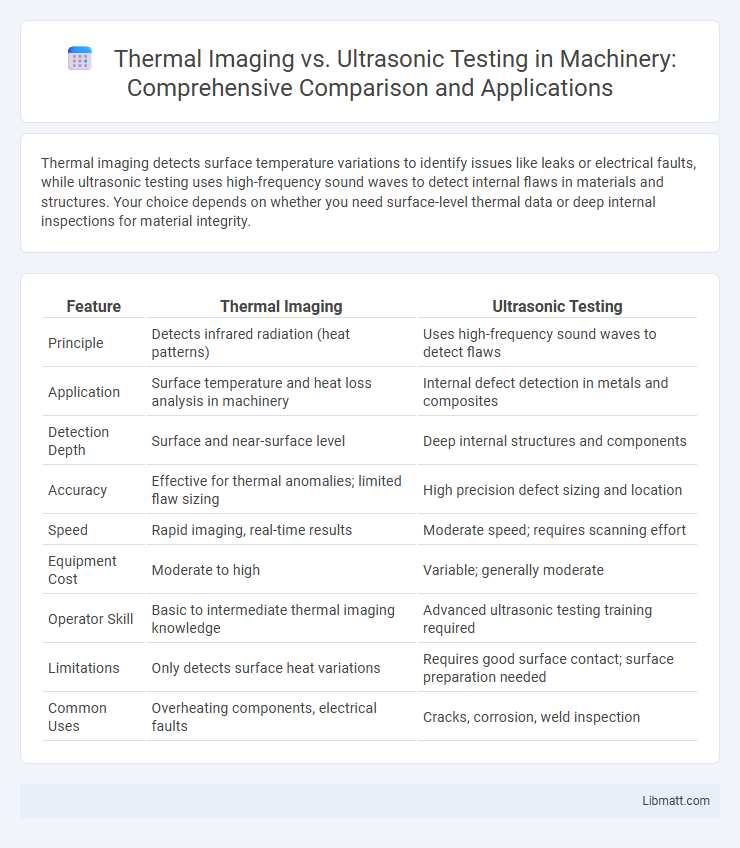

Thermal imaging detects surface temperature variations to identify issues like leaks or electrical faults, while ultrasonic testing uses high-frequency sound waves to detect internal flaws in materials and structures. Your choice depends on whether you need surface-level thermal data or deep internal inspections for material integrity.

Table of Comparison

| Feature | Thermal Imaging | Ultrasonic Testing |

|---|---|---|

| Principle | Detects infrared radiation (heat patterns) | Uses high-frequency sound waves to detect flaws |

| Application | Surface temperature and heat loss analysis in machinery | Internal defect detection in metals and composites |

| Detection Depth | Surface and near-surface level | Deep internal structures and components |

| Accuracy | Effective for thermal anomalies; limited flaw sizing | High precision defect sizing and location |

| Speed | Rapid imaging, real-time results | Moderate speed; requires scanning effort |

| Equipment Cost | Moderate to high | Variable; generally moderate |

| Operator Skill | Basic to intermediate thermal imaging knowledge | Advanced ultrasonic testing training required |

| Limitations | Only detects surface heat variations | Requires good surface contact; surface preparation needed |

| Common Uses | Overheating components, electrical faults | Cracks, corrosion, weld inspection |

Introduction to Thermal Imaging and Ultrasonic Testing

Thermal imaging utilizes infrared cameras to detect temperature variations on surfaces, enabling the identification of heat patterns related to equipment faults or insulation defects. Ultrasonic testing employs high-frequency sound waves to detect internal flaws or measure material thickness by analyzing the reflected signals. Both non-destructive testing methods offer crucial insights for predictive maintenance and quality assurance in industrial applications.

How Thermal Imaging Works

Thermal imaging works by detecting infrared radiation emitted from objects, converting temperature variations on surfaces into visible thermal images. This non-contact method reveals heat patterns, enabling the identification of defects, insulation failures, or electrical issues without physical intervention. It is especially effective for monitoring temperature changes across large areas, providing real-time data for preventive maintenance and quality control.

Principles of Ultrasonic Testing

Ultrasonic testing operates on the principle of high-frequency sound waves transmitting through materials to detect internal flaws or measure thickness. When these sound waves encounter a boundary, such as a crack or inclusion, part of the wave reflects back and is captured by a sensor, providing detailed information about the material's integrity. Your choice between thermal imaging and ultrasonic testing depends on the specific inspection criteria, but ultrasonic testing offers precise defect localization and depth measurement through its wave reflection analysis.

Key Applications of Thermal Imaging

Thermal imaging excels in detecting heat patterns for preventative maintenance, electrical inspections, and building diagnostics by identifying hotspots, insulation failures, and moisture intrusion. It provides non-contact, real-time temperature data, making it ideal for monitoring mechanical equipment and detecting thermal anomalies before failures occur. Your ability to visualize temperature variations enhances safety and efficiency across industrial, automotive, and construction sectors.

Common Uses for Ultrasonic Testing

Ultrasonic testing is commonly used in the non-destructive evaluation of materials, especially for detecting internal flaws, measuring thickness, and inspecting welds in metals and composites. Industries such as aerospace, automotive, and construction rely on ultrasonic testing to ensure structural integrity and prevent failures. By understanding these applications, you can select the appropriate method for accurate and reliable inspection results.

Accuracy and Limitations: Thermal Imaging

Thermal imaging provides accurate detection of surface temperature variations, making it effective for identifying insulation defects, moisture intrusion, and electrical faults. Its accuracy can be compromised by environmental factors such as ambient temperature, wind, and surface emissivity, limiting its ability to detect subsurface issues. You should consider these limitations when selecting thermal imaging for precise diagnostics in maintenance and inspection tasks.

Precision and Constraints of Ultrasonic Testing

Ultrasonic testing offers high precision by detecting internal flaws and measuring material thickness with millimeter accuracy, making it ideal for detailed inspections in critical components. Constraints of ultrasonic testing include limitations in inspecting rough or irregular surfaces, requiring couplants, and difficulty in detecting defects near the surface or in complex geometries. You should consider these factors when choosing between thermal imaging, which provides a broader overview but less depth penetration, and ultrasonic testing for your inspection needs.

Cost and Equipment Comparison

Thermal imaging equipment typically costs between $2,000 and $20,000 depending on resolution and features, while ultrasonic testing devices range from $5,000 to $50,000 based on frequency capabilities and complexity. Thermal imaging offers non-contact inspections with minimal setup time, making it cost-effective for surface temperature analysis, whereas ultrasonic testing requires couplants and skilled operators for precise internal defect detection. Maintenance and calibration costs are generally higher for ultrasonic equipment due to sophisticated electronics, contrasting with the relatively lower upkeep expenses of thermal cameras.

Choosing the Right Method for Your Inspection Needs

Thermal imaging excels in detecting surface temperature variations, making it ideal for identifying electrical faults, insulation defects, and moisture intrusion quickly over large areas. Ultrasonic testing provides precise measurements of internal material thickness and detects subsurface flaws with high accuracy, essential for inspecting welds, pipelines, and structural components. Selecting the right inspection method depends on factors such as the type of defect, inspection environment, material properties, and required detection depth.

Future Trends in Non-Destructive Testing Technologies

Thermal imaging and ultrasonic testing are evolving with advancements in AI and machine learning, enabling enhanced defect detection and analysis speed in non-destructive testing (NDT). Future trends emphasize integration of real-time data analytics, automated anomaly recognition, and improved sensor sensitivity to detect minute structural flaws. These technologies aim to increase inspection accuracy, reduce downtime, and lower costs across industries such as aerospace, manufacturing, and infrastructure maintenance.

Thermal imaging vs ultrasonic testing Infographic

libmatt.com

libmatt.com