A spindle motor provides direct rotation to the spindle for consistent speed and torque, ideal for general machining tasks, while a servo spindle offers precise control over speed and position, enhancing accuracy and performance in complex operations. Your choice depends on the required precision and application complexity in your machining process.

Table of Comparison

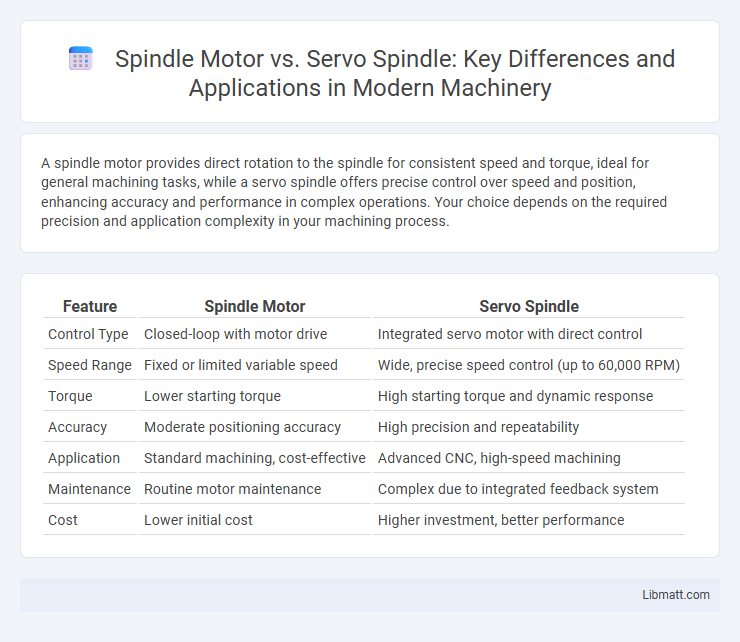

| Feature | Spindle Motor | Servo Spindle |

|---|---|---|

| Control Type | Closed-loop with motor drive | Integrated servo motor with direct control |

| Speed Range | Fixed or limited variable speed | Wide, precise speed control (up to 60,000 RPM) |

| Torque | Lower starting torque | High starting torque and dynamic response |

| Accuracy | Moderate positioning accuracy | High precision and repeatability |

| Application | Standard machining, cost-effective | Advanced CNC, high-speed machining |

| Maintenance | Routine motor maintenance | Complex due to integrated feedback system |

| Cost | Lower initial cost | Higher investment, better performance |

Introduction to Spindle Motor and Servo Spindle

Spindle motors are electric motors designed to rotate machine tool spindles at high speeds, commonly used in CNC machinery for precision and efficiency. Servo spindles integrate a servo motor directly into the spindle unit, providing enhanced control over speed, torque, and positioning for advanced machining applications. The key distinction lies in the servo spindle's ability to offer dynamic response and precise feedback, improving machining accuracy and performance.

Key Differences Between Spindle Motor and Servo Spindle

Spindle motors provide direct drive with high rotational speeds suited for precision CNC machining, while servo spindles integrate a servo motor and spindle in one unit, offering enhanced torque control and dynamic response. Key differences include the spindle motor's simpler design and lower cost versus the servo spindle's superior accuracy and adaptability for complex machining tasks. Your choice depends on the need for speed consistency versus torque precision in manufacturing applications.

Working Principles of Spindle Motors

Spindle motors operate using electromagnetic induction to generate rotational motion directly in the shaft, providing high precision and speed control. Unlike servo spindles, which integrate a servo motor with a spindle for enhanced torque and positioning accuracy, spindle motors rely on compact, brushless designs to deliver smooth and reliable performance. The working principle centers on converting electrical energy into mechanical rotation through stator and rotor interactions, critical for CNC machining and high-speed applications.

Servo Spindle: How It Operates

A servo spindle operates using a high-precision servo motor that provides controlled rotational speed and torque, ensuring accurate positioning and stable performance during machining. The integration of feedback systems such as encoders allows real-time monitoring and adjustment, optimizing spindle responsiveness and reducing mechanical wear. Your CNC machine benefits from enhanced speed control, improved machining accuracy, and extended spindle lifespan with a servo spindle setup.

Performance Comparison: Spindle Motor vs Servo Spindle

Spindle motors deliver consistent rotational speed with lower maintenance, ideal for high-speed applications requiring reliability and efficiency. Servo spindles offer superior precision and dynamic response, enabling advanced control over torque and acceleration for complex machining tasks. Performance comparison highlights spindle motors' strength in steady operation, while servo spindles excel in versatility and exact positioning.

Precision and Control: Which is Superior?

Servo spindles deliver superior precision and control compared to traditional spindle motors due to their integrated feedback systems and closed-loop control mechanisms. This allows for exact speed regulation, rapid response to load changes, and minimal runout, making servo spindles ideal for high-precision machining applications. In contrast, spindle motors lack direct feedback, resulting in less precise motion control and reduced accuracy in demanding manufacturing environments.

Application Areas for Spindle Motor and Servo Spindle

Spindle motors are commonly used in high-speed machining applications like PCB drilling and light milling, where precision and speed are critical but heavy load capacity is less demanding. Servo spindles excel in CNC machining centers and heavy-duty milling, offering superior torque control and dynamic response for complex, high-precision tasks such as aerospace part manufacturing. Understanding your application's specific requirements will help determine whether a spindle motor or servo spindle delivers optimal performance and efficiency.

Efficiency and Energy Consumption Analysis

Spindle motors typically offer higher efficiency due to their simpler design and lower power requirements, resulting in reduced energy consumption during continuous operation. Servo spindles provide precise speed and torque control, which can optimize energy use in variable load conditions, enhancing overall machine performance. Your choice between the two depends on the balance between energy efficiency and the need for dynamic control in your specific application.

Cost Considerations: Initial and Maintenance

Spindle motors generally have lower initial costs due to simpler design and fewer components, making them ideal for budget-conscious applications. Servo spindles, while more expensive upfront because of integrated feedback systems and precision engineering, often reduce long-term maintenance costs through enhanced reliability and self-regulating features. Evaluating total cost of ownership should consider both initial investment and expected maintenance frequency for optimal financial planning.

Choosing Between Spindle Motor and Servo Spindle: Factors to Consider

Choosing between a spindle motor and a servo spindle depends on factors such as precision requirements, speed control, and torque demands for your machining application. Servo spindles offer superior torque at low speeds and precise positioning ideal for complex, high-accuracy tasks, while spindle motors excel in high-speed operations with simpler control systems. Evaluate your specific needs for speed variability, load capacity, and control complexity to determine the optimal spindle solution for your equipment.

Spindle motor vs servo spindle Infographic

libmatt.com

libmatt.com