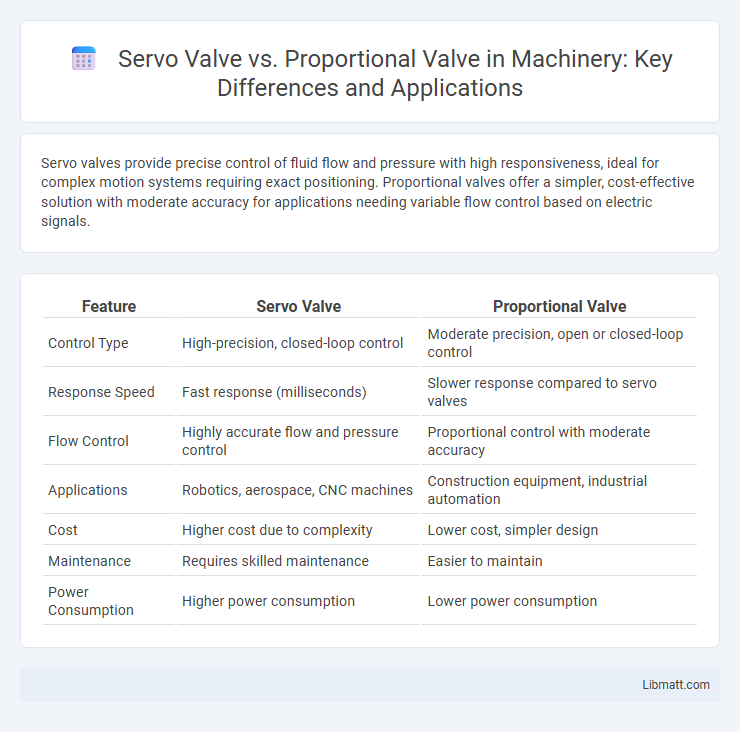

Servo valves provide precise control of fluid flow and pressure with high responsiveness, ideal for complex motion systems requiring exact positioning. Proportional valves offer a simpler, cost-effective solution with moderate accuracy for applications needing variable flow control based on electric signals.

Table of Comparison

| Feature | Servo Valve | Proportional Valve |

|---|---|---|

| Control Type | High-precision, closed-loop control | Moderate precision, open or closed-loop control |

| Response Speed | Fast response (milliseconds) | Slower response compared to servo valves |

| Flow Control | Highly accurate flow and pressure control | Proportional control with moderate accuracy |

| Applications | Robotics, aerospace, CNC machines | Construction equipment, industrial automation |

| Cost | Higher cost due to complexity | Lower cost, simpler design |

| Maintenance | Requires skilled maintenance | Easier to maintain |

| Power Consumption | Higher power consumption | Lower power consumption |

Introduction to Servo and Proportional Valves

Servo valves and proportional valves are critical components in hydraulic and pneumatic control systems, designed to regulate fluid flow with precision. Servo valves offer high accuracy and fast response by continuously adjusting the servomechanism based on feedback signals, making them ideal for complex, dynamic applications. Your choice between the two depends on the required control resolution and application complexity, as proportional valves provide simpler, cost-effective flow control without feedback for less sensitive systems.

Fundamental Operating Principles

Servo valves operate by converting electrical signals into precise fluid flow and pressure control through a feedback loop, using a spool or flapper nozzle mechanism to achieve high accuracy. Proportional valves control fluid flow or pressure by varying the electrical input signal to modulate the valve opening directly, resulting in smoother and more continuous control compared to on/off valves. The key distinction lies in servo valves' closed-loop feedback providing superior dynamic response and accuracy, while proportional valves offer simpler, open-loop control suitable for less demanding applications.

Key Differences Between Servo and Proportional Valves

Servo valves offer precise control of hydraulic fluid flow and pressure through feedback mechanisms, enabling accurate positioning and speed control in dynamic systems. Proportional valves provide variable flow or pressure proportional to an electrical input but typically lack the high responsiveness and fine control of servo valves. Key differences include servo valves' closed-loop feedback for higher accuracy versus proportional valves' open-loop control suited for simpler, cost-effective applications.

Performance Characteristics Comparison

Servo valves offer high precision, rapid response times, and excellent repeatability, making them ideal for fine control applications requiring fast and accurate positioning. Proportional valves provide moderate precision with smoother flow control and lower cost, suited for applications where response speed is less critical but variable output is needed. Servo valves typically exhibit superior linearity and bandwidth, while proportional valves deliver better reliability and simpler maintenance under moderate performance demands.

Application Areas: Where Each Valve Excels

Servo valves excel in high-precision applications such as aerospace flight control systems, industrial robotics, and hydraulic test stands, where precise control of fluid flow and position is critical. Proportional valves are ideal for moderate-precision tasks, including machine tool control, mobile hydraulics in agricultural and construction equipment, and general industrial automation requiring smooth control of speed and force. The choice depends on the required sensitivity, response time, and cost-effectiveness, with servo valves offering superior performance for demanding, high-dynamic applications and proportional valves suited for cost-sensitive, less complex control tasks.

Precision and Control Capabilities

Servo valves provide superior precision and control capabilities due to their fast response times and fine flow regulation, making them ideal for applications requiring high accuracy. Proportional valves offer good control but generally lack the exactness and rapid responsiveness needed for intricate motion control tasks. The choice between the two depends on the complexity of the system and the demand for precise hydraulic actuation.

Maintenance and Reliability Factors

Servo valves require meticulous maintenance due to their complex design and sensitivity to contamination, which can affect precision and responsiveness. Proportional valves generally offer higher reliability with less frequent maintenance, as their simpler construction reduces the risk of component wear and failure. You should consider servo valves for applications demanding high accuracy but be prepared for rigorous maintenance schedules, whereas proportional valves suit environments prioritizing durability and operational consistency.

Cost Implications and Efficiency

Servo valves generally incur higher upfront costs due to precision components and advanced control capabilities, but they offer superior efficiency in dynamic response and load handling. Proportional valves present a more cost-effective solution with simpler mechanics, making them ideal for applications where moderate accuracy and control suffice. Your choice between the two should balance budget constraints against performance demands to optimize overall system efficiency.

Selection Criteria for Industrial Applications

Selecting between a servo valve and a proportional valve for industrial applications depends on precision, response time, and load capacity requirements. Servo valves offer superior accuracy and fast dynamic response, suitable for high-performance systems demanding precise control, whereas proportional valves provide reliable, cost-effective solutions for moderate precision and lower flow rates. Your choice hinges on balancing system complexity, budget constraints, and the specific application's control demands.

Future Trends in Valve Technology

Servo valves and proportional valves are evolving with advancements in smart materials and digital control technologies, enabling higher precision and faster response times. Integration of IoT sensors and AI-driven diagnostics is enhancing predictive maintenance and operational efficiency in valve systems. Future trends highlight increased miniaturization and energy-efficient designs, supporting automation in aerospace, robotics, and industrial applications.

Servo valve vs proportional valve Infographic

libmatt.com

libmatt.com