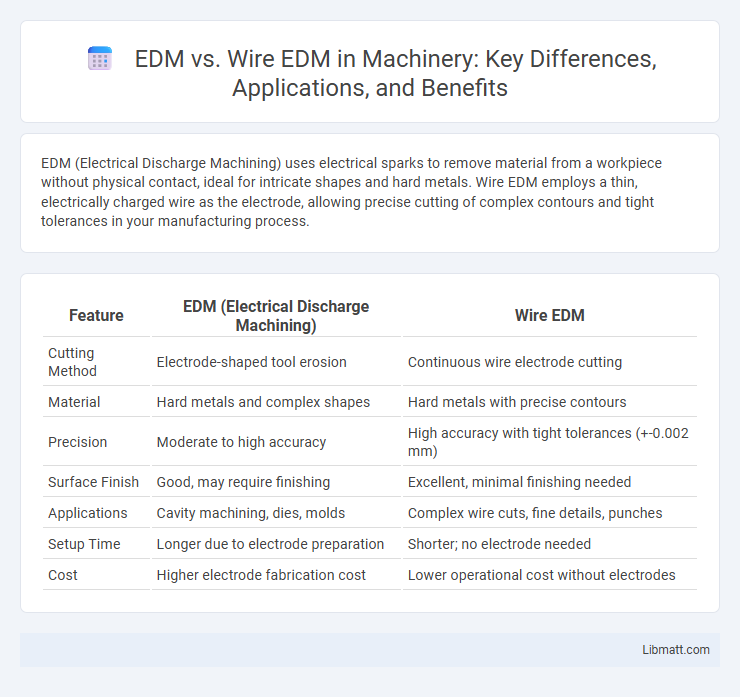

EDM (Electrical Discharge Machining) uses electrical sparks to remove material from a workpiece without physical contact, ideal for intricate shapes and hard metals. Wire EDM employs a thin, electrically charged wire as the electrode, allowing precise cutting of complex contours and tight tolerances in your manufacturing process.

Table of Comparison

| Feature | EDM (Electrical Discharge Machining) | Wire EDM |

|---|---|---|

| Cutting Method | Electrode-shaped tool erosion | Continuous wire electrode cutting |

| Material | Hard metals and complex shapes | Hard metals with precise contours |

| Precision | Moderate to high accuracy | High accuracy with tight tolerances (+-0.002 mm) |

| Surface Finish | Good, may require finishing | Excellent, minimal finishing needed |

| Applications | Cavity machining, dies, molds | Complex wire cuts, fine details, punches |

| Setup Time | Longer due to electrode preparation | Shorter; no electrode needed |

| Cost | Higher electrode fabrication cost | Lower operational cost without electrodes |

Introduction to EDM and Wire EDM

Electrical Discharge Machining (EDM) uses controlled electrical sparks to erode metal, ideal for creating complex shapes in hard materials. Wire EDM employs a continuously moving thin wire as an electrode to cut precise, intricate contours in conductive materials with high accuracy and minimal thermal distortion. Your choice between EDM and Wire EDM hinges on the need for either versatile material erosion or precision contour cutting.

How EDM and Wire EDM Work

EDM (Electrical Discharge Machining) removes material by generating controlled electrical sparks between an electrode and the workpiece, creating precise cavities in hard metals. Wire EDM uses a continuously fed thin wire as the electrode, allowing for intricate cuts and complex shapes with exceptional accuracy. Your choice depends on the specific machining requirements, as traditional EDM is suited for creating molds and dies, while Wire EDM excels in fine detail and tight tolerances.

Key Differences Between EDM and Wire EDM

EDM (Electrical Discharge Machining) utilizes a single electrode to erode material from a workpiece through controlled electrical discharges, ideal for creating complex cavities and shapes. Wire EDM employs a continuously moving thin wire as the electrode, enabling precise cutting of intricate contours and tight tolerances in hard materials. Your choice depends on whether you need detail through cavity machining with EDM or precise, fine contour cutting provided by Wire EDM.

Materials Suitable for EDM vs Wire EDM

EDM excels with hard, conductive materials such as hardened steels, titanium, and exotic alloys, making it ideal for complex cavity machining in tool and die applications. Wire EDM specifically suits electrically conductive metals including stainless steel, brass, copper, and carbide, allowing precise cutting of intricate shapes and fine details. Both processes require materials with good electrical conductivity but differ in application flexibility and material thickness limitations.

Precision and Accuracy Comparison

EDM (Electrical Discharge Machining) and wire EDM both deliver high precision, but wire EDM excels with tighter tolerances often reaching 0.001 mm due to its thin, continuously fed wire electrode. The controlled spark erosion in wire EDM allows for superior accuracy in cutting complex geometries and fine details compared to conventional EDM processes, which are better suited for removing larger amounts of material. Your choice between these methods should depend on the required precision and complexity of the workpiece.

Surface Finish Quality: EDM vs Wire EDM

Wire EDM delivers superior surface finish quality compared to traditional EDM, achieving surface roughness values as low as Ra 0.1 um due to its precise, controlled wire electrode and finely tuned spark discharge. EDM typically produces rougher surfaces, with Ra values commonly ranging from 1 to 3 um, influenced by the size of the graphite or copper electrode and the dielectric fluid used. The enhanced precision of Wire EDM minimizes heat-affected zones and recast layers, resulting in smoother finishes ideal for intricate molds and high-precision components.

Applications of EDM and Wire EDM

EDM (Electrical Discharge Machining) is primarily used for creating complex shapes and fine details in hard materials where traditional machining is ineffective, such as molds, dies, and aerospace components. Wire EDM excels in precise cutting of intricate contours and thin sections, often applied in medical device manufacturing, tool and die making, and micro-machining. Your choice between EDM and Wire EDM should consider the required precision, material thickness, and specific application needs.

Advantages and Disadvantages of Each Method

EDM (Electrical Discharge Machining) offers precision machining of complex shapes with minimal mechanical stress, making it ideal for hard materials and intricate details, but it tends to have slower material removal rates and higher operational costs. Wire EDM excels in producing fine, complex cuts with tight tolerances and minimal kerf width, providing cleaner edges and faster machining of thinner materials, yet it is limited by the thickness of workpieces and the need for continuous wire replacement. Both methods require dielectric fluids for discharge stability, and selection depends on factors such as material hardness, geometry complexity, surface finish requirements, and production volume.

Cost Considerations in EDM and Wire EDM

EDM (Electrical Discharge Machining) generally incurs lower initial setup costs compared to wire EDM, making it suitable for simpler or less precise projects with limited budgets. Wire EDM, while more expensive due to its precision and consumable wire costs, offers higher accuracy and is ideal for complex, intricate parts requiring tight tolerances. Evaluating your project requirements helps determine whether the reduced cost of EDM or the precision investment of wire EDM provides better overall value.

Choosing the Right Process for Your Project

EDM (Electrical Discharge Machining) uses electrical sparks to shape hard metals, ideal for complex contours and small, detailed parts. Wire EDM, a subset of EDM, employs a thin, continuously fed wire as an electrode, offering superior precision and clean, narrow cuts perfect for intricate shapes and tight tolerances. Understanding your project's material, required accuracy, and geometry will help you select the process that ensures optimal efficiency and finish quality.

EDM vs wire EDM Infographic

libmatt.com

libmatt.com