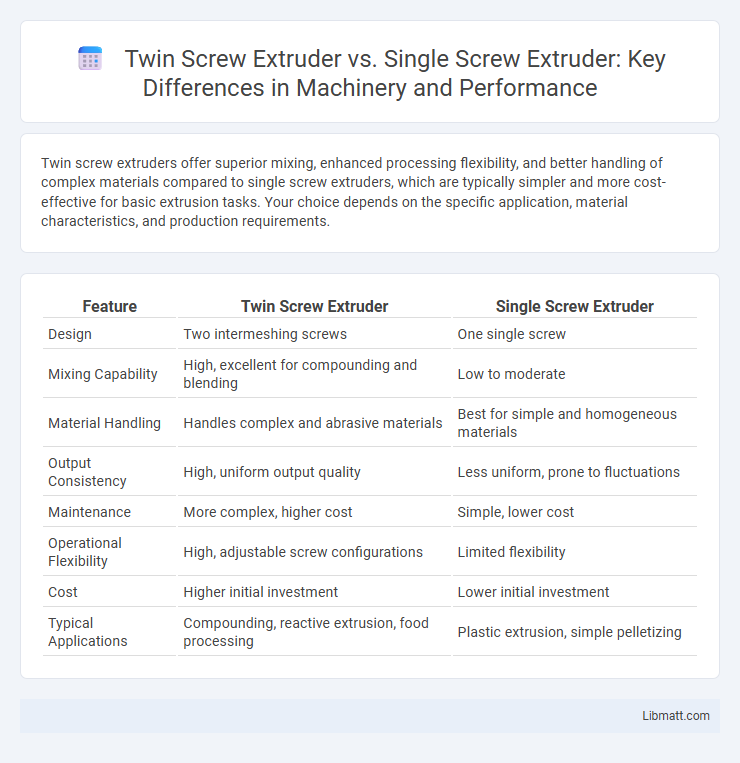

Twin screw extruders offer superior mixing, enhanced processing flexibility, and better handling of complex materials compared to single screw extruders, which are typically simpler and more cost-effective for basic extrusion tasks. Your choice depends on the specific application, material characteristics, and production requirements.

Table of Comparison

| Feature | Twin Screw Extruder | Single Screw Extruder |

|---|---|---|

| Design | Two intermeshing screws | One single screw |

| Mixing Capability | High, excellent for compounding and blending | Low to moderate |

| Material Handling | Handles complex and abrasive materials | Best for simple and homogeneous materials |

| Output Consistency | High, uniform output quality | Less uniform, prone to fluctuations |

| Maintenance | More complex, higher cost | Simple, lower cost |

| Operational Flexibility | High, adjustable screw configurations | Limited flexibility |

| Cost | Higher initial investment | Lower initial investment |

| Typical Applications | Compounding, reactive extrusion, food processing | Plastic extrusion, simple pelletizing |

Introduction to Extrusion Technology

Extrusion technology utilizes mechanical devices to melt and shape polymer materials by forcing them through a die. Twin screw extruders provide enhanced mixing, better temperature control, and greater processing flexibility compared to single screw extruders. Single screw extruders are simpler, cost-effective, and suitable for straightforward melting and conveying tasks but lack advanced mixing capabilities.

Overview of Single Screw Extruders

Single screw extruders consist of a single rotating screw inside a cylindrical barrel, primarily designed for melting, mixing, and shaping thermoplastic materials. They offer simplicity, cost-effectiveness, and ease of maintenance, making them ideal for uniform materials and straightforward applications. Your choice of a single screw extruder suits well for processes requiring consistent output with lower complexity and less demanding mixing requirements.

Understanding Twin Screw Extruders

Twin screw extruders offer superior mixing and compounding capabilities compared to single screw extruders due to their intermeshing screws that provide enhanced shear and heat transfer. Their design allows for precise control over material processing, making them ideal for complex formulations and reactive extrusion applications. You benefit from improved product uniformity and efficient processing when choosing a twin screw extruder for your manufacturing needs.

Key Differences Between Single and Twin Screw Extruders

Twin screw extruders feature intermeshing screws that enhance material mixing and provide superior control over temperature and pressure, unlike single screw extruders which rely on one screw primarily for melting and conveying. Twin screws excel in processes requiring precise compounding, devolatilization, and high shear mixing, while single screw extruders are more suited for simple melting and shaping tasks with lower operational complexity. Additionally, twin screw extruders offer better adaptability to processing a wide range of materials and formulations, increasing efficiency in advanced applications such as plastics, food, and pharmaceuticals.

Material Compatibility and Processing Flexibility

Twin screw extruders offer superior material compatibility and processing flexibility compared to single screw extruders, handling a wider range of polymers and additives with enhanced mixing capabilities. Your choice of twin screw extruder allows precise control over temperature and shear, optimizing complex formulations and improving product consistency. Single screw extruders are generally limited to simpler materials and processes, making twin screw technology the preferred option for advanced compounding and reactive extrusion applications.

Mixing Efficiency: Single vs Twin Screw

Twin screw extruders offer superior mixing efficiency compared to single screw extruders due to their intermeshing screws which enhance shear and distributive mixing capabilities. Single screw extruders typically provide less uniform mixing, relying more on shear generated by screw flights and barrel design, leading to limited control over material homogeneity. Twin screw systems excel in compounding and processing complex materials where consistent dispersion and blending are critical for product quality.

Throughput and Output Comparison

Twin screw extruders generally offer higher throughput and more consistent output compared to single screw extruders due to their enhanced mixing and shear capabilities. The intermeshing screws of twin screw extruders facilitate better material handling and improved processing of complex formulations, resulting in increased production rates. Single screw extruders tend to have lower throughput and less uniform output, making them suitable for simpler applications with moderate production demands.

Energy Consumption and Operational Costs

Twin screw extruders typically exhibit higher energy consumption than single screw extruders due to their more complex intermeshing screws which require increased power input for enhanced mixing and shear capabilities. However, twin screw extruders often reduce overall operational costs by improving product quality and process stability, minimizing waste and downtime. Single screw extruders generally have lower initial energy demands but may incur higher long-term costs due to less efficient mixing and increased maintenance needs.

Typical Applications of Each Extruder Type

Twin screw extruders excel in compounding, reactive extrusion, and blending of complex materials, making them ideal for applications in the food, pharmaceutical, and polymer industries where precise mixing and temperature control are critical. Single screw extruders are commonly used for simple melting and shaping processes, such as producing plastic films, sheets, and pipes in mass manufacturing due to their cost-effectiveness and straightforward operation. The choice between twin screw and single screw extruders hinges on material complexity and processing requirements, with twin screws favored for high-shear and multi-material tasks, and single screws for uniform, single-material extrusion.

Choosing the Right Extruder for Your Production Needs

Twin screw extruders offer superior mixing and consistent output for complex formulations, making them ideal for high-precision applications in industries like food processing and plastics. Single screw extruders, known for simplicity and cost-effectiveness, are suited for straightforward tasks with lower shear requirements, such as basic plastic extrusion or pelletizing. Evaluating factors like material type, production volume, and desired product quality is essential for selecting the right extruder technology for efficient manufacturing.

Twin screw extruder vs single screw extruder Infographic

libmatt.com

libmatt.com