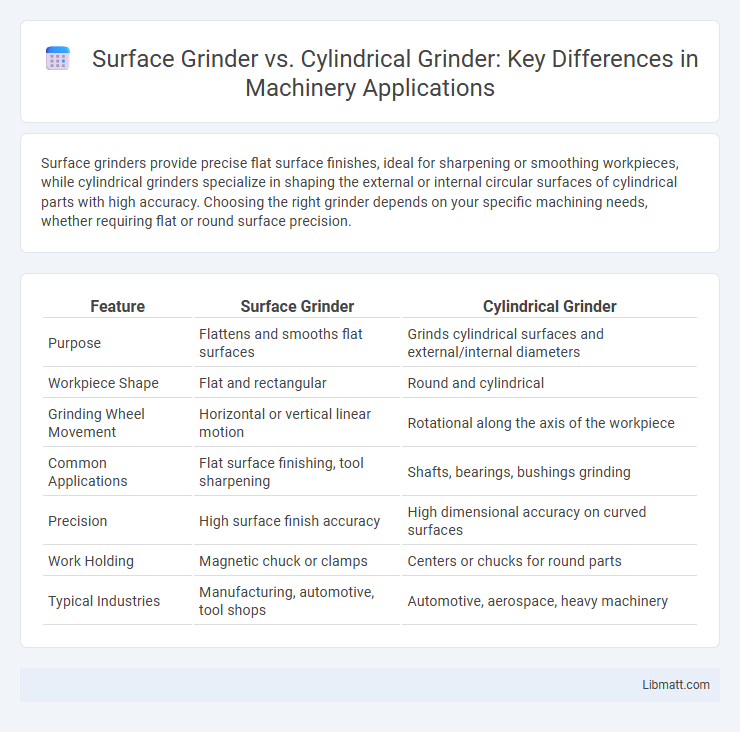

Surface grinders provide precise flat surface finishes, ideal for sharpening or smoothing workpieces, while cylindrical grinders specialize in shaping the external or internal circular surfaces of cylindrical parts with high accuracy. Choosing the right grinder depends on your specific machining needs, whether requiring flat or round surface precision.

Table of Comparison

| Feature | Surface Grinder | Cylindrical Grinder |

|---|---|---|

| Purpose | Flattens and smooths flat surfaces | Grinds cylindrical surfaces and external/internal diameters |

| Workpiece Shape | Flat and rectangular | Round and cylindrical |

| Grinding Wheel Movement | Horizontal or vertical linear motion | Rotational along the axis of the workpiece |

| Common Applications | Flat surface finishing, tool sharpening | Shafts, bearings, bushings grinding |

| Precision | High surface finish accuracy | High dimensional accuracy on curved surfaces |

| Work Holding | Magnetic chuck or clamps | Centers or chucks for round parts |

| Typical Industries | Manufacturing, automotive, tool shops | Automotive, aerospace, heavy machinery |

Introduction to Surface and Cylindrical Grinders

Surface grinders precisely finish flat surfaces using a spinning abrasive wheel, ideal for creating smooth, accurate planar shapes on metal workpieces. Cylindrical grinders specialize in shaping the outer diameter of cylindrical objects, employing a rotating grinding wheel and workpiece to achieve tight tolerances and fine surface finishes. Each grinder type uses distinct mechanisms tailored to specific machining needs, optimizing precision and efficiency in manufacturing processes.

Key Differences Between Surface and Cylindrical Grinders

Surface grinders primarily remove material from flat surfaces using a rotating abrasive wheel, producing smooth, precise finishes, while cylindrical grinders shape the external or internal cylindrical surfaces of workpieces, ensuring accurate roundness and size. Surface grinders are best suited for flat parts and tool sharpening, whereas cylindrical grinders handle complex shapes like shafts and rollers with controlled diameters and concentricity. The choice depends on the workpiece geometry: flat for surface grinding, cylindrical or conical for cylindrical grinding.

Surface Grinder: Definition and Applications

A surface grinder is a precision machine tool designed to produce smooth, flat surfaces by removing material using a rotating abrasive wheel. It is commonly used in manufacturing and metalworking industries for finishing parts such as tools, dies, and machine components to achieve tight tolerances and surface finishes. Key applications include grinding flat surfaces on metal plates, tools, and fixtures, ensuring dimensional accuracy and improved surface quality.

Cylindrical Grinder: Definition and Applications

A cylindrical grinder is a precision machine tool used to shape the outside or inside of round objects by rotating the workpiece against a grinding wheel. It is commonly applied in manufacturing automotive components, aerospace parts, and precision bearings due to its ability to achieve high accuracy and smooth surface finishes on cylindrical surfaces. Your choice of a cylindrical grinder ensures consistent dimensional tolerances for shafts, rollers, and other cylindrical parts requiring concentricity and fine surface quality.

Types of Surface Grinding Machines

Surface grinding machines include horizontal spindle, vertical spindle, and rotary table grinders, each designed for specific flat surface finishing tasks. Horizontal spindle grinders use a wheel spinning parallel to the workpiece surface, ideal for precision flat surfaces, while vertical spindle grinders apply the wheel perpendicular for intricate contours. Your choice depends on the surface geometry and finish requirements, highlighting how different surface grinder types compare to cylindrical grinders, which focus on external cylindrical surfaces.

Types of Cylindrical Grinding Machines

Cylindrical grinding machines are classified into external, internal, and centerless grinders, each designed for specific grinding tasks on cylindrical surfaces. External cylindrical grinders focus on the outer surfaces of shafts, while internal grinders work on bore surfaces inside the workpiece. Centerless grinding eliminates the need for centers or chucks by supporting the workpiece between a grinding wheel and a regulating wheel, enabling high-precision, high-volume production.

Workpiece Compatibility and Shapes Processed

Surface grinders excel at processing flat or planar workpieces, producing smooth and precise surfaces ideal for components like machine bases or tool parts. Cylindrical grinders are designed for workpieces with cylindrical shapes, effectively shaping rods, shafts, and other rounded components with high accuracy. Your choice depends on whether you need flat surface finishing or precision contouring of cylindrical parts.

Grinding Precision and Surface Finish Comparison

Surface grinders excel in producing flat, smooth surfaces with high precision, achieving tolerances often within +-0.0001 inches, ideal for components requiring exact planar finishes. Cylindrical grinders specialize in shaping round surfaces, delivering precise diameters and fine surface finishes with tolerances typically around +-0.0002 inches, suitable for shafts and cylindrical parts. Your choice depends on whether the workpiece demands flatness or rotational symmetry, impacting the grinding precision and surface finish required.

Advantages and Limitations of Each Grinder

Surface grinders excel in producing flat, smooth surfaces with high precision, making them ideal for finishing tasks on flat workpieces, but they are limited in handling cylindrical shapes. Cylindrical grinders specialize in shaping round objects with superior accuracy and can work on both external and internal surfaces, though they require more setup time and are less efficient for flat surfaces. Your choice depends on the geometry of the workpiece and the desired finish, balancing the surface grinder's speed and flatness against the cylindrical grinder's versatility and precision on round parts.

Choosing the Right Grinder for Your Needs

Surface grinders excel at producing precise flat surfaces, ideal for finishing metal plates or tools, while cylindrical grinders specialize in shaping round components with high accuracy. Your choice depends on the specific geometry of the workpiece and desired surface finish; surface grinders suit flat workpieces, whereas cylindrical grinders handle cylindrical parts efficiently. Understanding the operational differences and application requirements helps you select the appropriate grinder to optimize machining quality and productivity.

Surface grinder vs cylindrical grinder Infographic

libmatt.com

libmatt.com