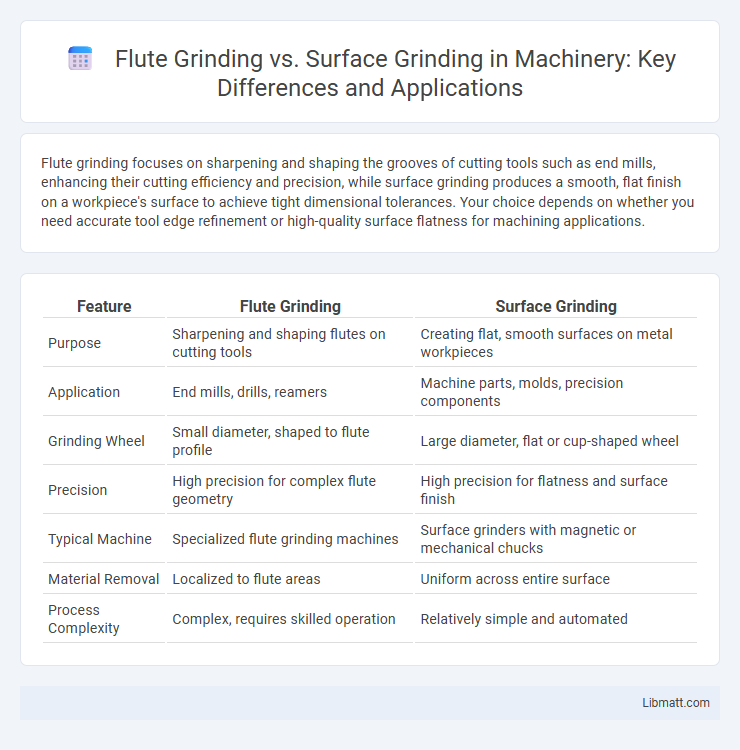

Flute grinding focuses on sharpening and shaping the grooves of cutting tools such as end mills, enhancing their cutting efficiency and precision, while surface grinding produces a smooth, flat finish on a workpiece's surface to achieve tight dimensional tolerances. Your choice depends on whether you need accurate tool edge refinement or high-quality surface flatness for machining applications.

Table of Comparison

| Feature | Flute Grinding | Surface Grinding |

|---|---|---|

| Purpose | Sharpening and shaping flutes on cutting tools | Creating flat, smooth surfaces on metal workpieces |

| Application | End mills, drills, reamers | Machine parts, molds, precision components |

| Grinding Wheel | Small diameter, shaped to flute profile | Large diameter, flat or cup-shaped wheel |

| Precision | High precision for complex flute geometry | High precision for flatness and surface finish |

| Typical Machine | Specialized flute grinding machines | Surface grinders with magnetic or mechanical chucks |

| Material Removal | Localized to flute areas | Uniform across entire surface |

| Process Complexity | Complex, requires skilled operation | Relatively simple and automated |

Introduction to Flute Grinding and Surface Grinding

Flute grinding is a precision machining process used to create the helical grooves or flutes on cutting tools such as end mills and drill bits, enhancing chip removal and cutting efficiency. Surface grinding involves the process of removing material from the flat surface of a workpiece through an abrasive wheel, providing a smooth and accurate finish for improved dimensional accuracy. Both techniques are essential in tool manufacturing, with flute grinding focusing on shaping tool geometry and surface grinding emphasizing surface quality and flatness.

Understanding Flute Grinding: Purpose and Applications

Flute grinding is a precision machining process specifically designed to shape and sharpen the helical grooves, or flutes, on cutting tools like drills and end mills, enhancing their cutting efficiency and chip evacuation. This technique is crucial for maintaining the tool's geometry and cutting performance, especially in applications requiring high accuracy and surface finish. Unlike surface grinding, which primarily smooths and levels flat surfaces, flute grinding focuses on the intricate contours of the flutes to improve tool lifespan and machining quality.

Surface Grinding: Fundamental Concepts

Surface grinding involves the use of a rotating abrasive wheel to create a smooth, flat finish on a workpiece's surface, ensuring precise dimensional accuracy and improved surface texture. This process is essential for achieving tight tolerances and high-quality finishes on metal parts, commonly used in tool and die making, automotive, and aerospace industries. Key parameters include wheel speed, feed rate, and depth of cut, all of which influence the surface roughness and material removal rate.

Key Differences Between Flute Grinding and Surface Grinding

Flute grinding is a specialized machining process that shapes the grooves or flutes on cutting tools, enhancing cutting performance and chip removal, whereas surface grinding focuses on creating flat, smooth surfaces on metal workpieces for precision finishing. The key differences lie in their applications, with flute grinding targeting the contours of tools like end mills and drills, and surface grinding used mainly for planar surfaces on components. Understanding these distinctions helps you select the right grinding technique to improve tool efficiency and workpiece quality.

Equipment and Tools Used in Flute vs Surface Grinding

Flute grinding employs specialized rotary tools such as diamond or CBN wheels designed for precision shaping of flute grooves on cutting tools, requiring high-speed spindles and accurate CNC control for intricate profiles. Surface grinding uses a flat, abrasive grinding wheel to create smooth, flat surfaces on metals and other materials, often utilizing magnetic chucks to secure workpieces during processing. Your choice between flute and surface grinding depends on the specific geometry and finish quality needed, with flute grinding demanding highly precise, profile-specific equipment compared to the more straightforward setup of surface grinding machines.

Material Removal Rates: Flute vs Surface Grinding

Flute grinding typically achieves lower material removal rates compared to surface grinding due to its precision focus on flute geometry and edge sharpness in cutting tools. Surface grinding excels at removing large volumes of material rapidly, providing a high material removal rate ideal for flat surfaces and bulk stock reduction. Your choice between flute and surface grinding should consider the balance between precision and efficiency, as flute grinding prioritizes accuracy while surface grinding emphasizes faster material removal.

Surface Finish and Precision: A Comparative Analysis

Flute grinding offers superior precision and intricate surface finish quality essential for cutting tool performance, enabling sharp edges and smooth contours crucial in flute geometry. Surface grinding excels in achieving flat, smooth surfaces with tight tolerances, making it ideal for workpieces requiring high flatness and surface finish uniformity. The choice between flute grinding and surface grinding depends on the complexity and specific tolerance requirements of the component, impacting overall machining accuracy and finish quality.

Typical Industries for Flute and Surface Grinding

Flute grinding is primarily utilized in the tool manufacturing and aerospace industries for producing precise flutes on cutting tools like drills and end mills, essential for efficient chip removal and cutting performance. Surface grinding is widely employed in automotive, mold and die, and heavy machinery sectors to achieve flat, smooth surfaces on metal components, ensuring tight tolerances and high-quality finishes. Both grinding methods are critical in industrial manufacturing but serve distinct purposes aligned with their respective application requirements.

Cost Efficiency and Production Considerations

Flute grinding offers higher precision for cutting tools, but it generally involves greater setup complexity and longer cycle times, leading to increased costs compared to surface grinding. Surface grinding excels in cost efficiency for flat surfaces and larger production runs due to faster processing and easier automation. Manufacturing environments prioritize flute grinding when tool performance is critical, while surface grinding suits high-volume, cost-sensitive applications.

Choosing the Right Grinding Technique for Your Application

Flute grinding excels in shaping and sharpening the cutting edges of drill bits and end mills, providing precise flute geometries essential for chip removal and cutting efficiency. Surface grinding is preferred for achieving flat, smooth surfaces on workpieces, ensuring dimensional accuracy and high-quality finishes. Understanding your application's requirements--whether it demands intricate flute profiles or flawless surface flatness--guides you in selecting the best grinding technique for optimal tool performance and longevity.

Flute grinding vs surface grinding Infographic

libmatt.com

libmatt.com