Box way guides provide superior rigidity and load capacity, making them ideal for heavy-duty machining applications, while linear rails offer smoother motion and higher precision suitable for high-speed, lightweight tasks. Your choice depends on whether you prioritize durability and stability or accuracy and speed in your machinery.

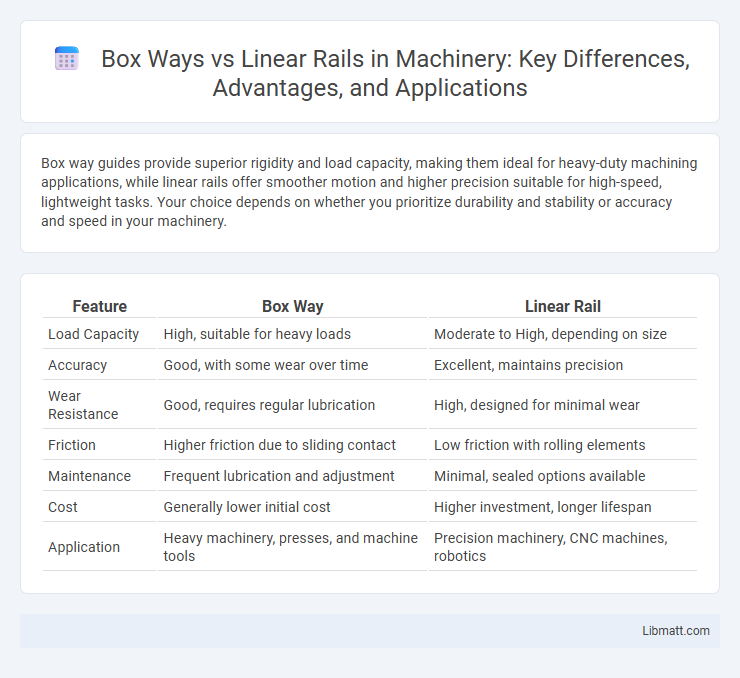

Table of Comparison

| Feature | Box Way | Linear Rail |

|---|---|---|

| Load Capacity | High, suitable for heavy loads | Moderate to High, depending on size |

| Accuracy | Good, with some wear over time | Excellent, maintains precision |

| Wear Resistance | Good, requires regular lubrication | High, designed for minimal wear |

| Friction | Higher friction due to sliding contact | Low friction with rolling elements |

| Maintenance | Frequent lubrication and adjustment | Minimal, sealed options available |

| Cost | Generally lower initial cost | Higher investment, longer lifespan |

| Application | Heavy machinery, presses, and machine tools | Precision machinery, CNC machines, robotics |

Introduction to Box Way and Linear Rail

Box ways provide sturdy, enclosed support with high load capacity and excellent stiffness, making them ideal for heavy-duty machining applications that require high rigidity. Linear rails, featuring rolling elements like ball bearings or rollers, offer smoother motion with lower friction and higher precision, suited for high-speed and high-accuracy operations. The choice between box ways and linear rails hinges on balancing load-bearing capabilities with the desired precision and speed in manufacturing processes.

What Are Box Ways?

Box ways are mechanical linear motion components featuring a rectangular or square-shaped guideway that ensures high rigidity and precise alignment. Their robust, enclosed structure provides superior resistance to twisting and bending forces compared to linear rails, making them ideal for heavy-duty machining applications. Understanding the advantages of box ways can help you select the best linear guide system for optimal machine performance and durability.

What Are Linear Rails?

Linear rails are precision-engineered components designed to provide smooth, accurate linear motion in machinery and equipment. Unlike box ways, which use sliding surfaces with larger contact areas, linear rails employ rolling elements such as ball bearings or rollers to minimize friction and wear. Your choice between box way and linear rail systems impacts load capacity, rigidity, and motion efficiency in applications like CNC machines, automation, and robotics.

Key Differences Between Box Ways and Linear Rails

Box ways provide robust load-carrying capacity and excellent rigidity due to their enclosed sliding surfaces, making them ideal for heavy-duty machining applications, while linear rails offer high precision and smooth motion with minimal friction favored in automated and CNC systems. Unlike box ways, which have larger contact areas and increased resistance to vibration and deflection, linear rails utilize rolling elements for higher speed and accuracy but may require more maintenance to prevent contamination. The key differences lie in load capacity, motion smoothness, durability under heavy loads, and the suitability for specific machining tasks or precision equipment.

Advantages of Box Way Systems

Box way systems provide superior load capacity and rigidity compared to linear rails, making them ideal for heavy-duty machining tasks and minimizing deflection under high stress. Their robust design enhances vibration damping, improving machining accuracy and surface finish quality. You benefit from increased machine stability and durability, which reduces maintenance costs and extends equipment lifespan.

Benefits of Linear Rail Systems

Linear rail systems offer superior precision and load capacity compared to box way designs, making them ideal for applications requiring high accuracy and smooth motion. Their reduced friction and minimal maintenance needs enhance machine efficiency and longevity. The modular nature of linear rails also allows for easier installation and scalability in various industrial automation setups.

Applications: Box Way vs Linear Rail

Box ways offer superior load capacity and rigidity, making them ideal for heavy machining applications such as milling and turning where high stability under significant forces is required. Linear rails excel in precision and smooth motion, commonly used in automation, CNC machines, and robotics where accuracy and low friction are critical. Selecting between box way and linear rail depends on the application's demands for load bearing, precision, and operating environment.

Durability and Maintenance Comparison

Box ways offer superior durability due to their robust contact surface and ability to handle heavy loads with minimal wear, making them ideal for demanding industrial applications. Linear rails provide high precision and smooth motion but often require more frequent maintenance, including lubrication and debris cleaning, to maintain optimal performance. Selecting between the two depends on Your need for long-lasting durability versus ease of maintenance and precision in motion control.

Cost Considerations and ROI

Box way guide systems generally incur lower upfront costs due to simpler design and manufacturing processes, making them attractive for budget-conscious projects. Linear rails, while more expensive initially, offer higher precision, durability, and reduced maintenance, delivering superior ROI through increased productivity and longer service life. Evaluating your specific application needs and lifespan expectations ensures the most cost-effective choice between box way and linear rail technologies.

Choosing the Best Guideway for Your CNC Machine

Box way guideways offer superior load capacity and rigidity, making them ideal for heavy-duty CNC machining tasks that demand high precision and durability. Linear rails excel in smooth, low-friction movement and are better suited for high-speed applications where accuracy and minimal maintenance are critical. Your choice depends on balancing the machine's operational speed, load requirements, and maintenance preferences to maximize performance and longevity.

Box way vs linear rail Infographic

libmatt.com

libmatt.com