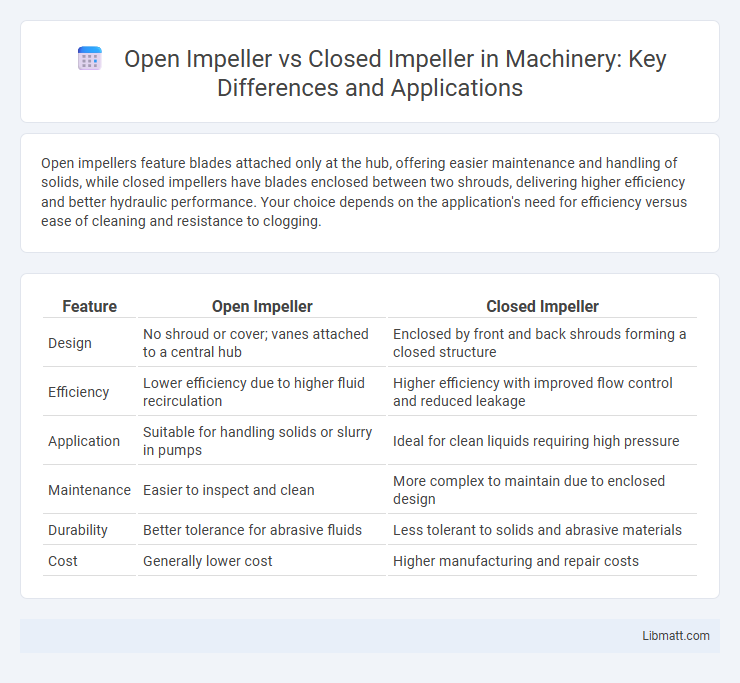

Open impellers feature blades attached only at the hub, offering easier maintenance and handling of solids, while closed impellers have blades enclosed between two shrouds, delivering higher efficiency and better hydraulic performance. Your choice depends on the application's need for efficiency versus ease of cleaning and resistance to clogging.

Table of Comparison

| Feature | Open Impeller | Closed Impeller |

|---|---|---|

| Design | No shroud or cover; vanes attached to a central hub | Enclosed by front and back shrouds forming a closed structure |

| Efficiency | Lower efficiency due to higher fluid recirculation | Higher efficiency with improved flow control and reduced leakage |

| Application | Suitable for handling solids or slurry in pumps | Ideal for clean liquids requiring high pressure |

| Maintenance | Easier to inspect and clean | More complex to maintain due to enclosed design |

| Durability | Better tolerance for abrasive fluids | Less tolerant to solids and abrasive materials |

| Cost | Generally lower cost | Higher manufacturing and repair costs |

Introduction to Impeller Types

Open impellers feature blades attached only at the hub, allowing easy inspection and cleaning, often used in applications with solids or debris. Closed impellers have both front and back shrouds enclosing the blades, providing higher efficiency and better fluid containment for clean liquid pumping. Selection depends on factors like fluid type, required efficiency, maintenance needs, and pump application.

What is an Open Impeller?

An open impeller features blades attached directly to the central hub without side walls, allowing easier maintenance and handling of solids or debris in the fluid. Its design offers less resistance and simpler cleaning compared to closed impellers, making it ideal for applications involving slurry, wastewater, or viscous liquids. Open impellers generally provide lower efficiency but superior durability in harsh operating conditions.

What is a Closed Impeller?

A closed impeller features a design where the vanes are sandwiched between two discs, providing enhanced efficiency and protection against leakage in pump systems. This structure improves hydraulic performance and reduces energy loss, making it ideal for handling clean, low-viscosity fluids. When selecting your pump components, a closed impeller ensures durability and precision in fluid control applications.

Key Design Differences

Open impellers feature blades attached only at the hub with no shroud, allowing for easier maintenance and better handling of solids, while closed impellers have blades enclosed between front and back shrouds, enhancing hydraulic efficiency and pressure generation. The design of open impellers results in increased wear and lower efficiency due to higher flow recirculation, whereas closed impellers offer improved strength and reduced hydraulic losses for higher performance in clean fluid applications. Material selection and manufacturing complexity also differ, with closed impellers requiring precise casting or machining to maintain tight tolerances, unlike the simpler construction of open impellers.

Performance Comparison

Open impellers typically deliver higher hydraulic efficiency in handling solids-laden or viscous fluids due to reduced clogging and easier maintenance, whereas closed impellers offer superior performance for clear liquids by minimizing leakage and maximizing pressure generation. Closed impellers provide better head and flow characteristics owing to their enclosed design, which enhances energy transfer and reduces slip losses. Performance comparison favors open impellers in abrasive or slurry applications and closed impellers in high-pressure, clean fluid scenarios, reflecting each design's optimized operational conditions.

Efficiency Considerations

Open impellers typically have lower efficiency due to increased hydraulic losses and exposure to wear, making them less suitable for high-pressure applications where energy conservation is critical. Closed impellers, with their enclosed design, provide higher efficiency by reducing leakage and improving flow control, resulting in better energy transfer and performance in demanding pumping systems. You should consider closed impellers for maximizing efficiency in operations requiring smooth fluid handling and reduced maintenance.

Applications of Open Impellers

Open impellers are widely used in applications involving handling viscous fluids, slurries, and solids-laden liquids due to their simple design and ease of maintenance. Common industries utilizing open impellers include wastewater treatment, chemical processing, and mining, where abrasion resistance and clogging prevention are critical. These impellers are preferred in pumps requiring frequent cleaning or inspection, offering efficient operation in harsh fluid environments.

Applications of Closed Impellers

Closed impellers are commonly used in applications requiring high efficiency and pressure, such as water treatment, chemical processing, and boiler feed pumps. They excel in handling clean or slightly contaminated liquids where minimal leakage and higher hydraulic efficiency are critical. Your systems benefit from enhanced performance and durability by selecting closed impellers for stable and high-pressure fluid transfer.

Maintenance and Durability

Open impellers offer easier maintenance due to their simple design, allowing for quick inspection, cleaning, and repair without disassembling the pump casing, reducing downtime. Closed impellers provide superior durability and efficiency by minimizing wear and corrosion risks, as their enclosed structure protects the blades from abrasive fluids and debris. However, closed impellers require more thorough disassembly for maintenance, increasing labor time and costs compared to open impellers.

Choosing the Right Impeller for Your System

Choosing the right impeller for your system depends on factors such as fluid type, efficiency requirements, and maintenance preferences. Open impellers offer easier maintenance and better handling of solids, making them ideal for abrasive or clog-prone fluids, while closed impellers provide higher efficiency and are suited for clean, low-viscosity liquids. Understanding your specific operational conditions will help you optimize pump performance and longevity.

Open impeller vs closed impeller Infographic

libmatt.com

libmatt.com