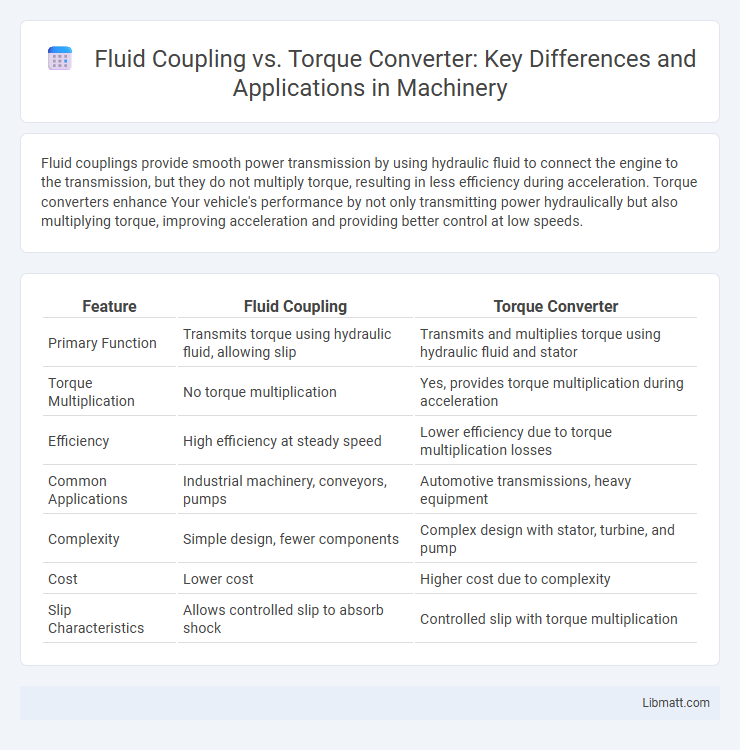

Fluid couplings provide smooth power transmission by using hydraulic fluid to connect the engine to the transmission, but they do not multiply torque, resulting in less efficiency during acceleration. Torque converters enhance Your vehicle's performance by not only transmitting power hydraulically but also multiplying torque, improving acceleration and providing better control at low speeds.

Table of Comparison

| Feature | Fluid Coupling | Torque Converter |

|---|---|---|

| Primary Function | Transmits torque using hydraulic fluid, allowing slip | Transmits and multiplies torque using hydraulic fluid and stator |

| Torque Multiplication | No torque multiplication | Yes, provides torque multiplication during acceleration |

| Efficiency | High efficiency at steady speed | Lower efficiency due to torque multiplication losses |

| Common Applications | Industrial machinery, conveyors, pumps | Automotive transmissions, heavy equipment |

| Complexity | Simple design, fewer components | Complex design with stator, turbine, and pump |

| Cost | Lower cost | Higher cost due to complexity |

| Slip Characteristics | Allows controlled slip to absorb shock | Controlled slip with torque multiplication |

Introduction to Fluid Coupling and Torque Converter

Fluid coupling and torque converter are essential components in automotive transmission systems designed to transmit engine power smoothly to the drivetrain. Fluid coupling provides a hydraulic link allowing torque transfer through fluid dynamics without mechanical connection, reducing shock and vibration. Torque converters build on this by incorporating a stator to multiply torque, enhancing your vehicle's acceleration and efficiency during various driving conditions.

Key Working Principles

Fluid coupling transmits rotational power by using a viscous fluid to transfer torque between the pump and turbine without mechanical engagement, allowing smooth power delivery and slip during acceleration. Torque converters enhance this principle by incorporating a stator between the pump and turbine that redirects fluid flow, multiplying torque and improving efficiency at low speeds. Both devices rely on fluid dynamics for power transmission but torque converters provide torque multiplication, making them ideal for varying load conditions in automatic transmissions.

Major Components Comparison

A fluid coupling primarily consists of a pump impeller, turbine runner, and a housing, enabling smooth power transmission without torque multiplication. In contrast, a torque converter includes a stator in addition to the pump and turbine, which alters fluid flow to multiply torque and improve vehicle acceleration. Understanding these major components helps you choose the best transmission solution for efficient power delivery and performance.

Function in Power Transmission

Fluid couplings transmit rotational power smoothly by using a hydraulic fluid to transfer torque from the input shaft to the output shaft, allowing for slip and reducing mechanical wear. Torque converters enhance this process by incorporating a stator and a turbine, which multiply torque during acceleration and improve overall power transfer efficiency. Understanding the distinction in power transmission function helps you select the right component for applications requiring variable torque and smooth startup performance.

Efficiency and Performance

Fluid couplings offer smooth power transmission by using hydraulic fluid to connect the engine and drivetrain but generally exhibit lower efficiency due to slippage under load. Torque converters improve performance with a built-in stator that redirects fluid flow, enhancing torque multiplication and reducing slippage, resulting in higher overall efficiency in varying speed conditions. Modern torque converters often incorporate lock-up clutches that further increase efficiency by creating a direct mechanical connection at cruising speeds.

Slip and Stall Characteristics

Fluid couplings exhibit a consistent slip that allows smooth power transmission but lack the stall torque multiplication found in torque converters. Torque converters provide variable slip and stall characteristics by using a stator, enabling your engine to deliver higher torque at low speeds for improved vehicle acceleration and performance. Understanding these differences helps optimize drivetrain efficiency based on your specific automotive requirements.

Applications in Industry and Automobiles

Fluid couplings are widely used in industrial applications such as conveyor systems, pumps, and crushers, where smooth torque transmission and shock absorption are crucial for protecting machinery. Torque converters are predominantly found in automobiles, particularly in automatic transmissions, providing variable torque multiplication and enabling efficient power transfer from the engine to the drivetrain. Your choice between these devices depends on the need for torque multiplication and precise vehicle control versus simple torque transmission and mechanical protection.

Advantages & Disadvantages

Fluid couplings offer smooth power transmission with minimal shock loads and simpler construction, making them more cost-effective and reliable for moderate torque applications. Torque converters provide torque multiplication and improved vehicle acceleration, enhancing performance at low speeds but come with increased complexity, weight, and higher fuel consumption. Fluid couplings lack torque multiplication, limiting efficiency in stop-and-go driving compared to torque converters which optimize power delivery and fuel economy in dynamic driving conditions.

Maintenance and Reliability

Fluid couplings require minimal maintenance due to their simple design and fewer moving parts, offering high reliability for consistent power transmission in industrial applications. Torque converters, while providing enhanced torque multiplication and smoother vehicle acceleration, involve more complex components like a stator and turbine, necessitating regular fluid checks and potential repairs to maintain optimal performance. Your choice between the two should consider the maintenance resources available and the reliability needed for the specific operational environment.

Choosing Between Fluid Coupling and Torque Converter

Choosing between fluid coupling and torque converter depends on the specific application requirements, such as the need for torque multiplication and smooth power transmission. Fluid couplings offer simple and efficient power transfer without torque multiplication, making them suitable for applications with steady load conditions. Torque converters provide variable torque multiplication, improved acceleration, and protection against shock loads, ideal for vehicles and machinery requiring dynamic performance.

Fluid coupling vs torque converter Infographic

libmatt.com

libmatt.com