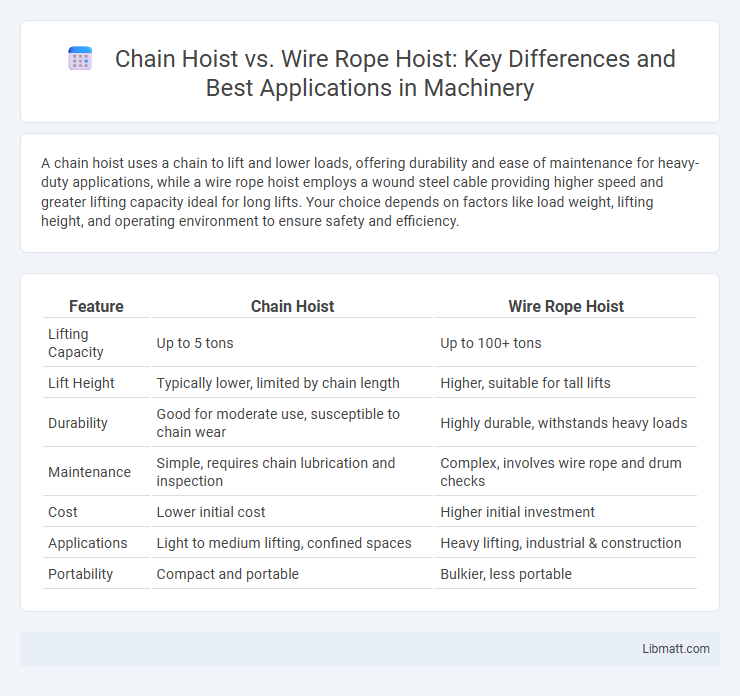

A chain hoist uses a chain to lift and lower loads, offering durability and ease of maintenance for heavy-duty applications, while a wire rope hoist employs a wound steel cable providing higher speed and greater lifting capacity ideal for long lifts. Your choice depends on factors like load weight, lifting height, and operating environment to ensure safety and efficiency.

Table of Comparison

| Feature | Chain Hoist | Wire Rope Hoist |

|---|---|---|

| Lifting Capacity | Up to 5 tons | Up to 100+ tons |

| Lift Height | Typically lower, limited by chain length | Higher, suitable for tall lifts |

| Durability | Good for moderate use, susceptible to chain wear | Highly durable, withstands heavy loads |

| Maintenance | Simple, requires chain lubrication and inspection | Complex, involves wire rope and drum checks |

| Cost | Lower initial cost | Higher initial investment |

| Applications | Light to medium lifting, confined spaces | Heavy lifting, industrial & construction |

| Portability | Compact and portable | Bulkier, less portable |

Introduction to Lifting Hoists

Lifting hoists are essential tools designed to raise and lower heavy loads safely and efficiently in industrial settings. Chain hoists utilize a chain loop, offering durability and resistance to harsh environments, making them ideal for heavy-duty lifting tasks. Wire rope hoists employ steel wire ropes, providing higher lifting capacities and smoother operation for precise load control in construction and manufacturing industries.

What is a Chain Hoist?

A chain hoist is a mechanical device used for lifting heavy loads by utilizing a chain wrapped around a drum or wheel. Its design provides high durability and precise control, especially in environments requiring frequent lifting and lowering operations. You can rely on a chain hoist for tasks demanding strong load-holding capacity and easy maintenance in industrial or construction settings.

What is a Wire Rope Hoist?

A wire rope hoist is a lifting device that uses a steel wire rope wound around a drum to raise or lower heavy loads with precision and durability. Known for its high load capacity and long service life, it is commonly used in industrial environments such as manufacturing plants and construction sites. Wire rope hoists offer superior strength compared to chain hoists, making them ideal for handling extremely heavy materials and equipment.

Key Differences Between Chain Hoists and Wire Rope Hoists

Chain hoists utilize a chain loop to lift and lower heavy loads, offering precise control and durability for moderate lifting tasks. Wire rope hoists employ a wire rope wound around a drum, providing higher lifting capacity and faster operation ideal for heavy-duty industrial applications. The key differences lie in load capacity, lifting speed, and suitability for various environments, with chain hoists favored for compact, low-to-medium weight lifting and wire rope hoists for larger, more demanding operations.

Load Capacity Comparison

Wire rope hoists typically offer higher load capacities than chain hoists, often handling loads exceeding 20 tons, making them suitable for heavy industrial applications. Chain hoists are generally rated for lighter loads, usually up to 5 tons, and are preferred for precise, moderate lifting tasks. Understanding your load requirements ensures you choose the right hoist for safety and efficiency in lifting operations.

Durability and Maintenance Requirements

Chain hoists offer superior durability due to their robust metal chains that resist stretching and wear, making them ideal for heavy-duty applications with minimal maintenance. Wire rope hoists require regular inspections and lubricant applications to prevent corrosion and fraying, which can increase maintenance efforts and costs over time. Understanding your operation's demands helps determine whether the lower upkeep of chain hoists or the flexibility of wire rope hoists better suits your durability and maintenance needs.

Application Scenarios: When to Use Each

Chain hoists are ideal for lifting heavy loads in confined spaces such as workshops, warehouses, and construction sites due to their compact design and durability in rugged environments. Wire rope hoists excel in applications requiring high lifting speeds and longer lift heights, commonly found in manufacturing plants, shipyards, and outdoor construction projects. Choosing between chain hoists and wire rope hoists depends on factors like load weight, lifting height, operating conditions, and the need for precision or speed.

Safety Considerations

Chain hoists offer robust safety features like overload protection and lower risk of wire rope failure due to their durable chain construction. Wire rope hoists require regular inspections for fraying, corrosion, and proper lubrication to prevent accidents caused by wire strand breakage. Ensuring your hoist is well-maintained and equipped with safety devices like limit switches and emergency brakes is critical for safe lifting operations.

Cost and Investment Analysis

Chain hoists generally offer a lower upfront cost compared to wire rope hoists, making them a budget-friendly option for light to medium lifting applications. Wire rope hoists, while more expensive initially, provide greater durability, higher load capacities, and reduced maintenance costs over time, leading to better long-term investment value. Evaluating your specific lifting requirements and total cost of ownership will help determine which hoist type aligns best with your operational budget and efficiency goals.

Choosing the Right Hoist for Your Needs

Selecting the right hoist depends on your specific lifting requirements, such as weight capacity, precision, and environment. Chain hoists excel in durability and compactness for heavy loads with slower lifting speeds, while wire rope hoists offer faster lifting and greater height capability, ideal for industrial settings. Evaluating your load characteristics and operational conditions will help determine whether a chain hoist or wire rope hoist best suits your lifting needs.

Chain hoist vs wire rope hoist Infographic

libmatt.com

libmatt.com