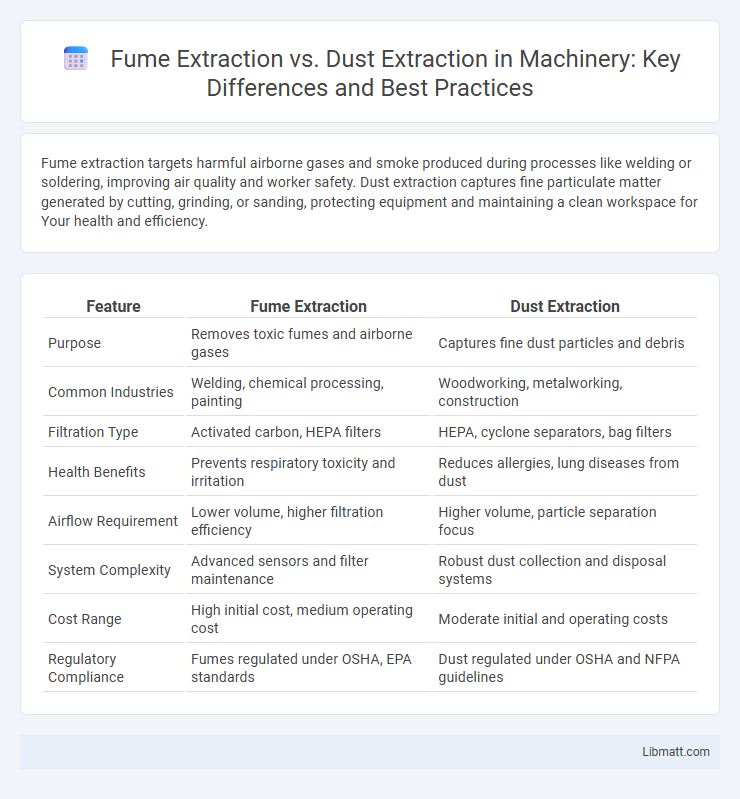

Fume extraction targets harmful airborne gases and smoke produced during processes like welding or soldering, improving air quality and worker safety. Dust extraction captures fine particulate matter generated by cutting, grinding, or sanding, protecting equipment and maintaining a clean workspace for Your health and efficiency.

Table of Comparison

| Feature | Fume Extraction | Dust Extraction |

|---|---|---|

| Purpose | Removes toxic fumes and airborne gases | Captures fine dust particles and debris |

| Common Industries | Welding, chemical processing, painting | Woodworking, metalworking, construction |

| Filtration Type | Activated carbon, HEPA filters | HEPA, cyclone separators, bag filters |

| Health Benefits | Prevents respiratory toxicity and irritation | Reduces allergies, lung diseases from dust |

| Airflow Requirement | Lower volume, higher filtration efficiency | Higher volume, particle separation focus |

| System Complexity | Advanced sensors and filter maintenance | Robust dust collection and disposal systems |

| Cost Range | High initial cost, medium operating cost | Moderate initial and operating costs |

| Regulatory Compliance | Fumes regulated under OSHA, EPA standards | Dust regulated under OSHA and NFPA guidelines |

Introduction to Fume and Dust Extraction

Fume extraction targets airborne gases and vapors produced by processes like welding or soldering, effectively removing toxic fumes to improve air quality and worker safety. Dust extraction focuses on capturing airborne particles generated from cutting, grinding, or sanding operations, preventing respiratory hazards and contamination. Choosing the appropriate system depends on the type of pollutants present, with fume extraction requiring filtration suited for gases and vapors, while dust extraction utilizes filtration designed for solid particulate matter.

Understanding Fume Extraction Systems

Fume extraction systems are designed to capture and filter harmful airborne contaminants generated during processes like welding, soldering, and chemical manufacturing, targeting gases, vapors, and fine particulate matter. These systems use specialized filters such as activated carbon or HEPA filters to efficiently remove toxic fumes, ensuring cleaner air and protecting respiratory health in your workspace. Unlike dust extraction which primarily handles larger particles like wood or metal dust, fume extraction focuses on microscopic and often chemically hazardous pollutants to maintain compliance with occupational safety standards.

Overview of Dust Extraction Solutions

Dust extraction solutions are designed to capture airborne particulate matter generated during industrial processes, improving air quality and worker safety. These systems typically use high-efficiency filters and cyclonic separators to remove dust particles from the air before releasing clean air back into the environment. Implementing advanced dust extraction technology reduces respiratory hazards and complies with occupational health standards.

Key Differences Between Fume and Dust Extraction

Fume extraction systems are designed specifically to capture hazardous airborne gases and vapors generated from processes like welding, soldering, and chemical applications, whereas dust extraction targets solid particulate matter produced by grinding, cutting, and sanding activities. Fume extraction utilizes high-efficiency filters such as activated carbon or HEPA to neutralize toxic fumes and odors, while dust extraction employs mechanical filtration methods to collect dust particles and prevent respiratory exposure. The key difference lies in the nature of the contaminants: fumes are gaseous pollutants requiring specialized filtration, whereas dust consists of solid particles necessitating robust dust collection and containment methods.

Applications of Fume Extraction in Industries

Fume extraction systems are critical in industries such as welding, metal fabrication, and chemical manufacturing to remove hazardous fumes and gases generated during processes like soldering and solder flux vaporization. These systems improve air quality by capturing fine particulates, toxic fumes, and volatile organic compounds (VOCs) at the source, protecting worker health and ensuring regulatory compliance with OSHA and NIOSH standards. Applications extend to pharmaceutical and electronics industries, where precise fume control is essential to maintain product integrity and prevent contamination.

Common Uses for Dust Extraction Technology

Dust extraction technology is commonly used in woodworking, metalworking, and construction industries to capture airborne particles generated during cutting, grinding, and sanding processes. It effectively improves air quality by removing fine dust and debris, which helps prevent respiratory issues and equipment damage. Typical applications include sawmills, foundries, and pharmaceutical manufacturing, where controlling particulate matter is critical for safety and product quality.

Health and Safety Benefits: Fume vs. Dust Extraction

Fume extraction systems specifically target hazardous airborne gases and vapors produced during welding, soldering, and chemical processes, significantly reducing respiratory risks such as metal fume fever and chronic lung conditions. Dust extraction captures particulate matter from grinding, sanding, and cutting operations, preventing inhalation of silica, asbestos, and other harmful dusts linked to silicosis and occupational asthma. Both technologies enhance workplace air quality, but selecting the appropriate system depends on the contaminant type to maximize health and safety benefits.

Equipment Features and Efficiency

Fume extraction systems are designed with specialized filters like activated carbon and HEPA to capture hazardous gases and fine particles, ensuring high filtration efficiency for welding and soldering applications. Dust extraction equipment typically uses cyclonic separators and cartridge filters to handle larger particulate matter from woodworking or construction, offering robust airflow and dust containment. Your choice between these systems should consider the specific contaminants and efficiency requirements to maintain a safe and clean workspace.

Maintenance and Cost Considerations

Fume extraction systems generally require more frequent filter replacements and specialized maintenance due to the hazardous nature of fumes, leading to higher operational costs compared to dust extraction systems, which often have longer-lasting filters and simpler upkeep. Dust extraction units typically involve routine cleaning of collection bins and periodic filter changes, making them more cost-effective and easier to maintain over time. Your choice between the two should consider the specific environmental hazards and the associated maintenance schedules to optimize both performance and budget.

Choosing the Right Extraction System for Your Needs

Fume extraction systems target harmful gases and vapors from welding, soldering, or chemical processes, while dust extraction efficiently captures particulate matter from grinding, cutting, or sanding. Selecting the right extraction system depends on the specific contaminants generated, workspace size, and regulatory safety standards applicable to your industry. Your choice should focus on optimizing air quality, ensuring worker health, and complying with occupational safety requirements.

Fume extraction vs dust extraction Infographic

libmatt.com

libmatt.com