Steel offers excellent strength and durability for general applications, while high-speed steel (HSS) provides superior heat resistance and cutting performance in demanding machining tasks. Choosing high-speed steel ensures your tools maintain sharpness and efficiency at higher temperatures, enhancing productivity and tool life.

Table of Comparison

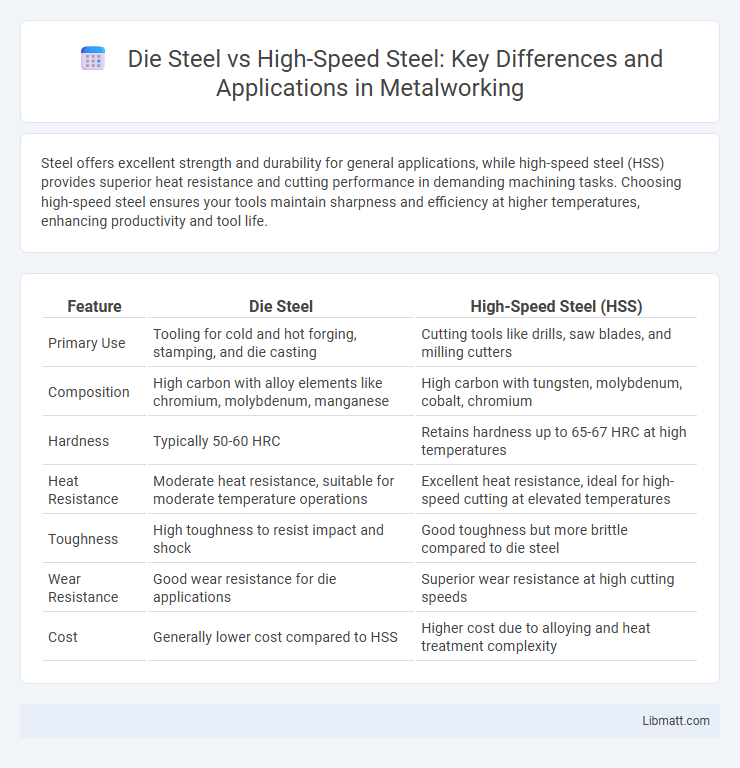

| Feature | Die Steel | High-Speed Steel (HSS) |

|---|---|---|

| Primary Use | Tooling for cold and hot forging, stamping, and die casting | Cutting tools like drills, saw blades, and milling cutters |

| Composition | High carbon with alloy elements like chromium, molybdenum, manganese | High carbon with tungsten, molybdenum, cobalt, chromium |

| Hardness | Typically 50-60 HRC | Retains hardness up to 65-67 HRC at high temperatures |

| Heat Resistance | Moderate heat resistance, suitable for moderate temperature operations | Excellent heat resistance, ideal for high-speed cutting at elevated temperatures |

| Toughness | High toughness to resist impact and shock | Good toughness but more brittle compared to die steel |

| Wear Resistance | Good wear resistance for die applications | Superior wear resistance at high cutting speeds |

| Cost | Generally lower cost compared to HSS | Higher cost due to alloying and heat treatment complexity |

Introduction to Die Steel and High-Speed Steel

Die steel, known for its exceptional hardness and wear resistance, is primarily used in manufacturing molds and dies requiring prolonged durability under high pressure. High-speed steel (HSS) offers superior toughness and heat resistance, making it ideal for cutting tools operating at elevated speeds and temperatures. Understanding the distinct properties of die steel and high-speed steel can significantly enhance your tool performance and application efficiency.

Composition Differences: Die Steel vs High-Speed Steel

Die steel primarily consists of high carbon content combined with manganese, chromium, and sometimes molybdenum, tailored for hardness and toughness to withstand high-impact stresses. High-speed steel (HSS) contains elevated amounts of tungsten, molybdenum, chromium, vanadium, and cobalt, enhancing its ability to retain hardness at elevated temperatures and resist wear during rapid cutting operations. The key compositional difference lies in HSS's alloying elements designed for heat resistance, whereas die steel emphasizes structural strength and durability under static loads.

Manufacturing Processes of Both Steels

Die steel is primarily produced through controlled melting processes such as vacuum induction melting and electro-slag remelting to enhance purity and uniformity, followed by forging and heat treatment to achieve desired mechanical properties. High-speed steel (HSS) manufacturing involves powder metallurgy techniques or conventional melting with alloying elements like tungsten, molybdenum, and cobalt, combined with precise heat treatment cycles to attain exceptional hardness and wear resistance. Both steels undergo specialized heat treatments such as quenching and tempering, but HSS requires more complex thermal processing to maintain performance at elevated cutting speeds.

Key Mechanical Properties Comparison

Die steel offers superior hardness and wear resistance, making it ideal for heavy-duty applications requiring long tool life, while high-speed steel (HSS) excels in toughness and heat resistance for high-temperature cutting operations. Your choice depends on the need for impact strength versus the ability to maintain hardness at elevated temperatures. Both materials possess excellent tensile strength, but HSS typically has better red hardness, enabling it to perform effectively under conditions of intense friction and heat.

Heat Resistance and Hardness Factors

Die steel offers superior hardness, typically ranging from 55 to 62 HRC, which ensures excellent wear resistance under high-pressure machining conditions. High-speed steel (HSS) exhibits greater heat resistance, retaining hardness up to temperatures around 600degC, making it ideal for cutting tools that operate at elevated speeds. While die steel provides durability under mechanical stress, HSS balances hardness with thermal stability for applications involving intense heat exposure.

Tool Life and Wear Resistance

Die steel offers superior wear resistance due to its higher carbon and alloy content, ensuring extended tool life in demanding stamping and cutting applications. High-speed steel contains tungsten and molybdenum, providing excellent hardness at elevated temperatures but typically exhibits lower wear resistance compared to die steel in abrasive environments. Selecting die steel maximizes durability in abrasive and high-pressure uses, while high-speed steel excels in high-temperature cutting operations where thermal endurance is critical.

Suitable Applications for Die Steel

Die steel is ideal for applications requiring high wear resistance and toughness, such as forging dies, extrusion dies, and blanking punches. Its superior hardness and ability to withstand repeated impact make it suitable for heavy-duty manufacturing processes. You can rely on die steel for tools that demand prolonged durability under high-stress conditions.

Suitable Applications for High-Speed Steel

High-Speed Steel (HSS) is highly suitable for cutting tools such as drills, taps, and milling cutters due to its excellent hardness, wear resistance, and ability to retain strength at elevated temperatures. This material excels in applications requiring sustained high-speed cutting and machining of hard metals like stainless steel and alloy steels. Its superior toughness also makes it ideal for tools experiencing frequent impact and thermal cycling during industrial manufacturing processes.

Cost Implications and Economic Considerations

Die steel generally offers a lower upfront cost compared to high-speed steel, making it a more budget-friendly option for large-scale production runs. However, high-speed steel provides superior wear resistance and longer tool life, which can reduce the frequency of replacements and maintenance expenses over time. Your choice between die steel and high-speed steel should weigh initial investment against long-term economic benefits to optimize overall cost efficiency.

Choosing the Right Steel: Key Factors to Consider

Choosing the right steel between die steel and high-speed steel depends on your application's required hardness, wear resistance, and heat tolerance. Die steel excels in toughness and impact resistance, ideal for heavy-duty stamping and forming, while high-speed steel offers superior hardness and heat resistance suited for cutting tools at high temperatures. Your decision should prioritize the specific mechanical properties and thermal stability required for optimal performance and tool longevity.

Die Steel vs High-Speed Steel Infographic

libmatt.com

libmatt.com