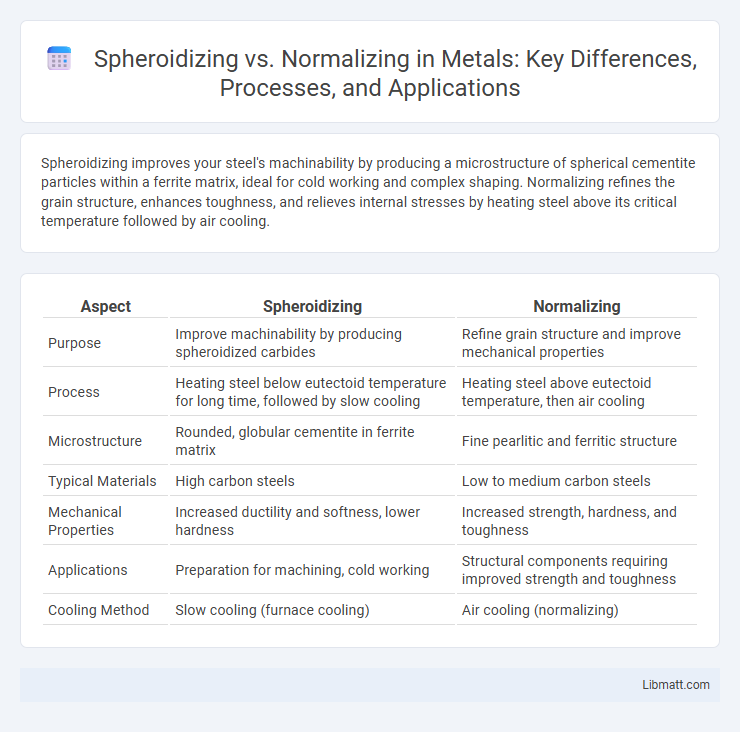

Spheroidizing improves your steel's machinability by producing a microstructure of spherical cementite particles within a ferrite matrix, ideal for cold working and complex shaping. Normalizing refines the grain structure, enhances toughness, and relieves internal stresses by heating steel above its critical temperature followed by air cooling.

Table of Comparison

| Aspect | Spheroidizing | Normalizing |

|---|---|---|

| Purpose | Improve machinability by producing spheroidized carbides | Refine grain structure and improve mechanical properties |

| Process | Heating steel below eutectoid temperature for long time, followed by slow cooling | Heating steel above eutectoid temperature, then air cooling |

| Microstructure | Rounded, globular cementite in ferrite matrix | Fine pearlitic and ferritic structure |

| Typical Materials | High carbon steels | Low to medium carbon steels |

| Mechanical Properties | Increased ductility and softness, lower hardness | Increased strength, hardness, and toughness |

| Applications | Preparation for machining, cold working | Structural components requiring improved strength and toughness |

| Cooling Method | Slow cooling (furnace cooling) | Air cooling (normalizing) |

Introduction to Heat Treatment Processes

Spheroidizing and normalizing are heat treatment processes applied to steel to modify its microstructure and improve mechanical properties. Spheroidizing involves heating steel just below the lower critical temperature for an extended period, promoting the formation of spherical cementite particles, which enhances machinability and ductility. Normalizing heats steel above the upper critical temperature followed by air cooling, resulting in a refined, uniform grain structure that increases strength and toughness.

Understanding Spheroidizing

Spheroidizing is a heat treatment process that transforms the microstructure of steel into spherical cementite particles within a ferrite matrix, enhancing machinability and ductility. This process is conducted at temperatures just below the eutectoid point for extended periods, allowing carbides to coalesce into globular shapes. Unlike normalizing, which refines grain size and improves strength, spheroidizing primarily aims to reduce hardness and increase the steel's formability for subsequent machining operations.

Overview of Normalizing

Normalizing is a heat treatment process where steel is heated to a temperature above its critical point and then air-cooled to refine grain size, improve uniformity, and enhance mechanical properties such as strength and toughness. Unlike spheroidizing, which aims to produce a soft and ductile microstructure by forming spherical cementite particles, normalizing results in a balanced structure ideal for further machining or mechanical use. Your materials can benefit from normalizing when improved hardness and fatigue resistance are required in structural applications.

Key Differences Between Spheroidizing and Normalizing

Spheroidizing is a heat treatment process aimed at producing a microstructure of spherical carbide particles within a ferritic matrix to improve machinability and ductility, typically performed at lower temperatures for extended periods. Normalizing involves heating steel above its critical temperature and air cooling to refine grain size, enhance mechanical properties like toughness and strength, and achieve a uniform microstructure. The key differences lie in their objectives: spheroidizing softens the steel by forming globular carbides, while normalizing refines the grain structure to balance hardness and toughness.

Microstructural Changes in Spheroidizing

Spheroidizing transforms steel microstructure by converting lamellar pearlite or cementite into spherical carbide particles within a ferrite matrix, enhancing ductility and machinability. This process reduces internal stresses and decreases hardness by promoting globular carbides, which eases deformation during subsequent forming operations. The resulting microstructure contrasts with normalizing, where finer pearlitic structures are formed, improving strength but maintaining higher hardness levels.

Microstructural Effects of Normalizing

Normalizing refines the grain structure by heating steel above its critical temperature and air cooling, producing a uniform and fine pearlitic microstructure. This process enhances mechanical properties such as toughness and strength by homogenizing the microstructure and reducing internal stresses. Unlike spheroidizing, which produces a soft and ductile ferrite-cementite matrix, normalizing results in a harder and more wear-resistant microstructure ideal for machining and structural applications.

Applications of Spheroidized Steels

Spheroidized steels are widely used in applications requiring high ductility and enhanced machinability, such as in automotive components, bearings, and cold heading materials. The spheroidizing process produces a microstructure with spherical carbides that improve wear resistance and reduce tool wear during machining. Your choice of spheroidized steel is ideal for parts subjected to significant deformation or requiring precision shaping.

Industrial Uses of Normalized Steels

Normalized steels are widely used in the automotive, structural, and heavy machinery industries due to their uniform grain structure, which provides improved toughness and machinability. The normalized heat treatment enhances mechanical properties like strength and ductility, making the steel ideal for gears, shafts, and structural components subjected to dynamic loading. This process ensures reliability and consistent performance in critical industrial applications requiring balanced hardness and flexibility.

Mechanical Properties: Spheroidized vs Normalized

Spheroidizing enhances ductility and machinability in steels by producing a microstructure with spherical cementite particles, resulting in lower hardness and tensile strength compared to normalized steels. Normalizing refines grain size through austenitizing and air cooling, improving toughness and strength while maintaining moderate hardness. The choice between spheroidizing and normalizing directly impacts the balance between strength, hardness, and machinability in steel components.

Choosing the Right Process: Factors to Consider

Selecting between spheroidizing and normalizing depends on the desired material properties and application requirements. Spheroidizing is ideal for improving machinability and ductility in high-carbon steels by producing rounded carbide structures, while normalizing refines grain size and enhances strength and toughness through controlled cooling. Factors such as steel composition, mechanical property targets, and subsequent manufacturing steps influence the choice of heat treatment process.

Spheroidizing vs Normalizing Infographic

libmatt.com

libmatt.com