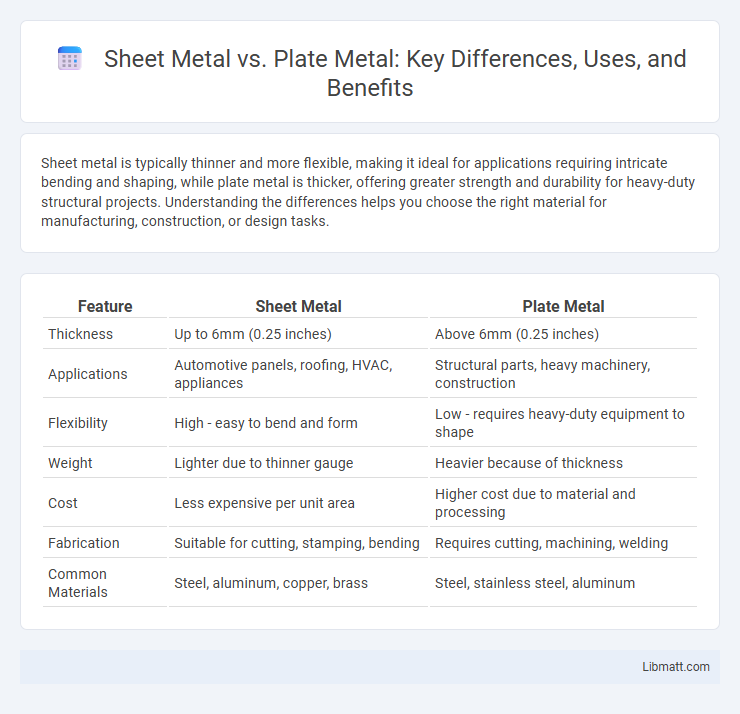

Sheet metal is typically thinner and more flexible, making it ideal for applications requiring intricate bending and shaping, while plate metal is thicker, offering greater strength and durability for heavy-duty structural projects. Understanding the differences helps you choose the right material for manufacturing, construction, or design tasks.

Table of Comparison

| Feature | Sheet Metal | Plate Metal |

|---|---|---|

| Thickness | Up to 6mm (0.25 inches) | Above 6mm (0.25 inches) |

| Applications | Automotive panels, roofing, HVAC, appliances | Structural parts, heavy machinery, construction |

| Flexibility | High - easy to bend and form | Low - requires heavy-duty equipment to shape |

| Weight | Lighter due to thinner gauge | Heavier because of thickness |

| Cost | Less expensive per unit area | Higher cost due to material and processing |

| Fabrication | Suitable for cutting, stamping, bending | Requires cutting, machining, welding |

| Common Materials | Steel, aluminum, copper, brass | Steel, stainless steel, aluminum |

Introduction to Sheet Metal and Plate Metal

Sheet metal refers to thin, flat pieces of metal typically less than 6mm thick, commonly used in automotive, aerospace, and construction industries due to its flexibility and ease of fabrication. Plate metal is thicker than 6mm, offering greater strength and durability, making it ideal for heavy-duty applications like shipbuilding, structural components, and industrial machinery. Both materials are essential in manufacturing, but their differences in thickness and mechanical properties determine their specific uses.

Defining Sheet Metal: Characteristics and Uses

Sheet metal refers to thin, flat pieces of metal typically less than 6mm thick, characterized by its flexibility and ease of fabrication through bending, cutting, and stamping processes. Commonly made from steel, aluminum, copper, or brass, sheet metal is widely used in automotive bodies, appliances, roofing, and HVAC systems due to its lightweight and versatile nature. Its precise thickness and uniform surface make it ideal for detailed, high-volume manufacturing and architectural applications.

Understanding Plate Metal: Key Features and Applications

Plate metal is characterized by its greater thickness, typically over 6mm, offering enhanced strength and durability compared to thinner sheet metal. Commonly used in heavy-duty applications such as construction, industrial machinery, and shipbuilding, plate metal provides superior structural support and wear resistance. Its ability to withstand high stress environments makes it ideal for fabricating load-bearing components and large-scale metal structures.

Thickness Differences: Sheet Metal vs Plate Metal

Sheet metal typically refers to metal with a thickness less than 6mm (0.25 inches), making it suitable for applications requiring lightweight and flexible materials. Plate metal, on the other hand, is generally thicker than 6mm, offering greater strength and rigidity for heavy-duty structural uses. This thickness difference directly influences the fabrication methods, with sheet metal often being stamped or bent, while plate metal is usually cut or machined.

Material Types Used in Sheet and Plate Metal

Sheet metal typically uses thinner materials such as aluminum, stainless steel, and mild steel, optimized for flexibility and ease of fabrication. Plate metal involves thicker materials, often made from carbon steel, stainless steel, and alloy steel, designed to endure higher mechanical stresses. Both sheet and plate metals vary in thickness, with sheet metal usually up to 6mm and plate metal exceeding that threshold, influencing the choice of material based on strength and application requirements.

Manufacturing Processes for Sheet and Plate Metal

Sheet metal manufacturing involves processes such as stamping, bending, and deep drawing, which allow precise shaping of thin metal sheets typically under 6mm thick. Plate metal, thicker than sheet metal, undergoes cutting operations like flame cutting, waterjet cutting, and heavy-duty machining to handle its greater thickness and strength. Understanding these manufacturing methods helps optimize Your project's material selection and fabrication efficiency.

Strength and Durability Comparison

Sheet metal typically ranges from 0.5 mm to 6 mm in thickness, offering flexibility but generally less strength compared to plate metal, which exceeds 6 mm thickness and provides higher structural integrity for heavy-duty applications. Plate metal's greater thickness enhances its resistance to impact, deformation, and wear, making it ideal for industrial machinery, construction, and structural components requiring durability. Strength properties vary by material type, but given equal alloy compositions, plate metal consistently outperforms sheet metal in load-bearing and longevity.

Cost Considerations: Sheet Metal vs Plate Metal

Sheet metal generally incurs lower costs due to its thinner gauge, ease of fabrication, and reduced material usage compared to plate metal, which is thicker and demands more heavy-duty processing equipment. Plate metal involves higher expenses related to cutting, welding, and handling because of its substantial thickness and weight, impacting overall project budgets. Cost efficiency in selecting sheet versus plate metal depends heavily on application requirements, material thickness, and fabrication complexity.

Common Industries and Applications

Sheet metal is widely used in automotive manufacturing, aerospace, and electronics industries due to its lightweight and versatile properties, ideal for creating car bodies, aircraft panels, and electronic enclosures. Plate metal finds common applications in heavy machinery, shipbuilding, and construction sectors where thicker, stronger material is essential for structural components, heavy equipment, and large frameworks. Your project's requirements for thickness and strength will determine whether sheet metal or plate metal is the optimal choice for durability and performance in these industries.

Choosing the Right Metal for Your Project

Selecting the right metal between sheet metal and plate metal depends on the thickness and application requirements of your project. Sheet metal, typically under 6mm thick, is ideal for lightweight, detailed work like automotive panels or HVAC ducts, while plate metal, thicker than 6mm, suits heavy-duty structural components and machinery bases. Understanding the material properties and mechanical strength ensures your project achieves optimal durability and performance.

Sheet Metal vs Plate Metal Infographic

libmatt.com

libmatt.com