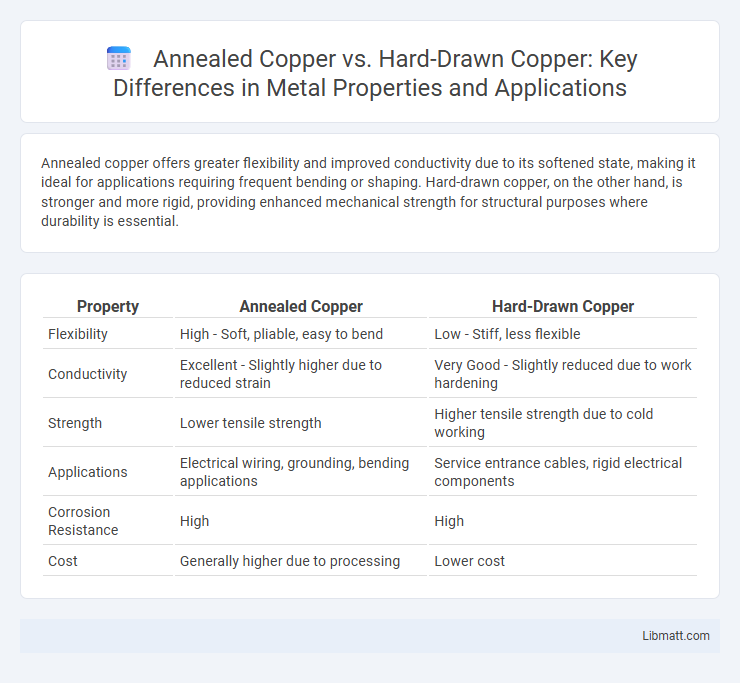

Annealed copper offers greater flexibility and improved conductivity due to its softened state, making it ideal for applications requiring frequent bending or shaping. Hard-drawn copper, on the other hand, is stronger and more rigid, providing enhanced mechanical strength for structural purposes where durability is essential.

Table of Comparison

| Property | Annealed Copper | Hard-Drawn Copper |

|---|---|---|

| Flexibility | High - Soft, pliable, easy to bend | Low - Stiff, less flexible |

| Conductivity | Excellent - Slightly higher due to reduced strain | Very Good - Slightly reduced due to work hardening |

| Strength | Lower tensile strength | Higher tensile strength due to cold working |

| Applications | Electrical wiring, grounding, bending applications | Service entrance cables, rigid electrical components |

| Corrosion Resistance | High | High |

| Cost | Generally higher due to processing | Lower cost |

Introduction to Annealed Copper and Hard-Drawn Copper

Annealed copper is a soft, flexible metal achieved through a heat treatment process that enhances its ductility and conductivity, making it ideal for electrical wiring and intricate applications requiring bending. Hard-drawn copper, on the other hand, is strengthened by cold working, resulting in increased tensile strength and rigidity, which suits structural applications where durability is critical. The choice between annealed and hard-drawn copper depends on the balance needed between flexibility and mechanical strength.

Chemical and Physical Properties Comparison

Annealed copper exhibits superior ductility and softness due to its heat treatment process, resulting in enhanced electrical conductivity and lower tensile strength compared to hard-drawn copper. Hard-drawn copper undergoes work hardening, increasing its tensile strength and hardness while reducing electrical conductivity and flexibility. Your choice depends on whether you prioritize mechanical strength or electrical performance and ease of fabrication in applications.

Manufacturing Processes Explained

Annealed copper undergoes a heat treatment process that softens the metal by heating it to a specific temperature and allowing it to cool slowly, enhancing its ductility and electrical conductivity. Hard-drawn copper is produced by mechanically deforming copper through drawing or rolling without heat treatment, resulting in a harder, stronger material with less flexibility. Your choice depends on whether you prioritize ease of bending and forming (annealed) or higher tensile strength and durability (hard-drawn) in manufacturing applications.

Electrical Conductivity Differences

Annealed copper offers higher electrical conductivity compared to hard-drawn copper due to its softer, more ductile structure that allows electrons to flow with less resistance. Hard-drawn copper, being mechanically strengthened through work hardening, exhibits slightly reduced conductivity as dislocations and strain impede electron movement. Understanding these conductivity differences is crucial for selecting the right copper type to optimize your electrical system's performance.

Mechanical Strength and Flexibility

Annealed copper exhibits lower mechanical strength but higher flexibility due to its softened microstructure achieved through heat treatment, making it ideal for applications requiring frequent bending or shaping. Hard-drawn copper, in contrast, offers increased mechanical strength and rigidity as a result of cold working processes, enhancing its resistance to deformation under stress. The choice between annealed and hard-drawn copper depends on the balance needed between ductility and tensile strength for specific electrical or structural applications.

Applications in Electrical Wiring and Electronics

Annealed copper, known for its excellent ductility and conductivity, is ideal for electrical wiring in residential and commercial buildings where flexibility and ease of installation are crucial. Hard-drawn copper offers enhanced mechanical strength, making it suitable for applications in electronics and electrical systems exposed to vibration or physical stress. Your choice between annealed and hard-drawn copper depends on the specific requirements for flexibility and durability in your electrical or electronic projects.

Cost and Availability Analysis

Annealed copper generally costs more due to its softer, more malleable properties achieved through heat treatment, making it widely available for applications requiring flexibility and easy bending. Hard-drawn copper, being stiffer and stronger without the annealing process, is typically less expensive and readily available for uses demanding durability and rigidity. Your choice depends on balancing budget constraints with the specific mechanical properties and availability required for your project.

Durability and Lifespan Considerations

Annealed copper offers enhanced flexibility but tends to have a shorter lifespan under mechanical stress due to its softer nature, making it more prone to damage over time. Hard-drawn copper is significantly more durable, maintaining its shape and strength under constant tension, which extends its operational lifespan in demanding electrical or industrial applications. Choosing between them depends on your specific needs for durability versus flexibility in your project.

Environmental Impact and Sustainability

Annealed copper, characterized by its softer and more malleable properties due to heat treatment, generally has a lower environmental impact during manufacturing because it requires less energy compared to hard-drawn copper, which undergoes extensive mechanical work hardening. Hard-drawn copper, while offering improved strength and durability that may extend product lifespan and reduce replacement frequency, typically consumes more energy and resources during production, affecting its overall sustainability footprint. Choosing between annealed and hard-drawn copper depends on balancing manufacturing energy consumption and product longevity to optimize environmental sustainability.

Choosing the Right Copper Type for Your Project

Annealed copper offers superior flexibility and enhanced conductivity, making it ideal for projects requiring frequent bending or complex wiring. Hard-drawn copper, with its increased tensile strength and rigidity, suits applications where structural durability and minimal deformation are critical. Understanding your project's mechanical demands helps you select the copper type that optimally balances performance and reliability.

Annealed copper vs hard-drawn copper Infographic

libmatt.com

libmatt.com