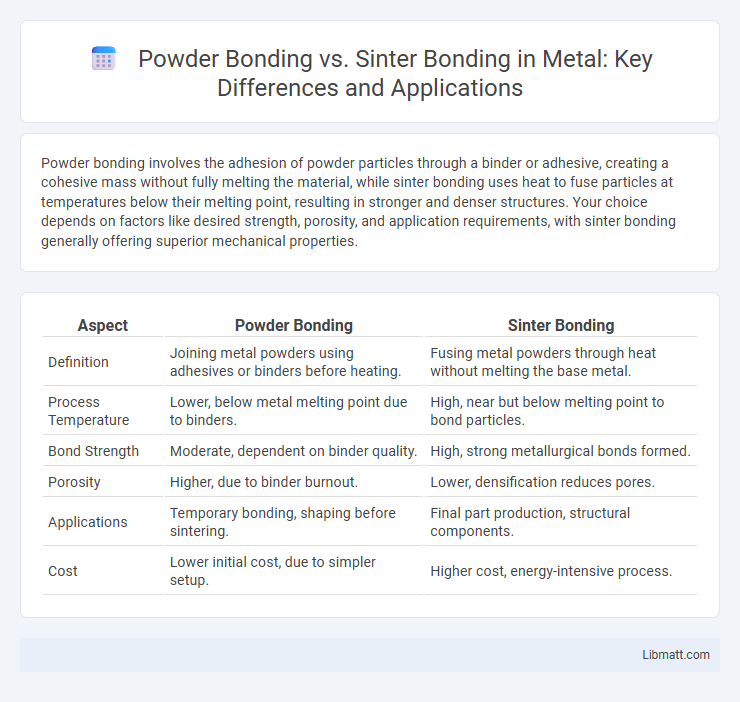

Powder bonding involves the adhesion of powder particles through a binder or adhesive, creating a cohesive mass without fully melting the material, while sinter bonding uses heat to fuse particles at temperatures below their melting point, resulting in stronger and denser structures. Your choice depends on factors like desired strength, porosity, and application requirements, with sinter bonding generally offering superior mechanical properties.

Table of Comparison

| Aspect | Powder Bonding | Sinter Bonding |

|---|---|---|

| Definition | Joining metal powders using adhesives or binders before heating. | Fusing metal powders through heat without melting the base metal. |

| Process Temperature | Lower, below metal melting point due to binders. | High, near but below melting point to bond particles. |

| Bond Strength | Moderate, dependent on binder quality. | High, strong metallurgical bonds formed. |

| Porosity | Higher, due to binder burnout. | Lower, densification reduces pores. |

| Applications | Temporary bonding, shaping before sintering. | Final part production, structural components. |

| Cost | Lower initial cost, due to simpler setup. | Higher cost, energy-intensive process. |

Introduction to Powder Bonding and Sinter Bonding

Powder bonding involves the process of mechanically or chemically adhering powder particles to form a cohesive mass without complete melting, often used in additive manufacturing and coatings. Sinter bonding, by contrast, relies on heating powder particles below their melting point until they fuse together through diffusion, commonly applied in metallurgy and ceramics to enhance material strength. Understanding these methods helps you choose the optimal bonding technique based on the desired material properties and application requirements.

Fundamental Principles of Powder Bonding

Powder bonding relies on mechanical interlocking and adhesive forces to join particles without significant heat, creating a bond through pressure or chemical agents. Sinter bonding involves heating powdered materials just below their melting point, causing diffusion and particle coalescence that form a strong, metallurgical bond. Understanding these fundamental principles helps you select the ideal bonding method based on desired strength, temperature tolerance, and material properties.

Core Mechanisms of Sinter Bonding

Sinter bonding primarily relies on atomic diffusion at particle interfaces under heat and pressure, resulting in neck growth and densification within the powder compact. This mechanism enhances mechanical strength by eliminating porosity and promoting metallurgical bonds between particles. In contrast, powder bonding often depends more on mechanical interlocking or adhesive forces without significant diffusion-driven bonding.

Material Suitability for Each Bonding Method

Powder bonding is ideal for materials with high melting points and complex compositions, such as tungsten and molybdenum, as it allows joining without melting the base metals. Sinter bonding suits materials like iron, nickel, and cobalt alloys that can densify through heat and pressure without fully liquefying, promoting strong metallurgical bonds. Selecting the appropriate bonding method depends on thermal stability, material hardness, and the intended application of the bonded components.

Process Parameters: Temperature, Pressure, and Time

Powder bonding typically occurs at lower temperatures and pressures compared to sinter bonding, with bonding achieved through mechanical interlocking and partial diffusion during short processing times. Sinter bonding requires higher temperatures, often approaching 70-90% of the material's melting point, combined with elevated pressures to promote atomic diffusion and neck growth over extended periods. Optimizing temperature, pressure, and time in sinter bonding enhances densification and mechanical strength, whereas powder bonding relies more on rapid compaction and moderate thermal exposure.

Comparative Advantages and Limitations

Powder bonding offers precise material control and flexibility in composition, making it ideal for complex shapes and customized properties, whereas sinter bonding excels in creating strong, dense parts with excellent mechanical strength due to high-temperature diffusion processes. Powder bonding may face limitations in achieving full density without additional treatments, while sinter bonding can be constrained by longer processing times and higher energy consumption. Understanding these trade-offs helps you select the optimal bonding technique based on application requirements such as strength, precision, and production efficiency.

Applications in Industry Sectors

Powder bonding is widely used in industries requiring rapid prototyping and lightweight component manufacturing, such as aerospace and automotive sectors, due to its ability to create complex geometries with minimal material waste. Sinter bonding finds extensive application in high-performance sectors like electronics and medical devices, where enhanced mechanical strength and thermal conductivity are critical. Both methods play vital roles in producing durable, high-precision parts in manufacturing, but the choice depends on industry-specific demands for structural integrity and production efficiency.

Quality Control and Bond Strength Analysis

Powder bonding requires rigorous quality control involving particle size distribution, binder uniformity, and compaction pressure to ensure consistent bond strength. Sinter bonding quality control emphasizes precise temperature profiles, atmosphere control, and dwell time to achieve optimal diffusion and grain boundary cohesion. Bond strength analysis for powder bonding relies on tensile and shear testing of green compacts, whereas sinter bonding strength is primarily evaluated through microstructural examination and fracture toughness measurements after heat treatment.

Environmental and Economic Considerations

Powder bonding typically consumes less energy compared to sinter bonding, leading to reduced greenhouse gas emissions and lower production costs. Sinter bonding requires higher temperatures and longer processing times, resulting in increased energy consumption and environmental impact. Economically, powder bonding offers cost savings through faster production cycles and less material waste, making it favorable for environmentally conscious manufacturing.

Future Trends in Powder and Sinter Bonding Technologies

Future trends in powder bonding and sinter bonding technologies emphasize enhanced material properties and process efficiencies through advanced nanoparticle manipulation and additive manufacturing integration. Researchers are exploring hybrid bonding techniques that combine powder metallurgy with sintering to improve mechanical strength and reduce porosity in complex components. Your manufacturing processes will benefit from these innovations by achieving higher precision, lower energy consumption, and improved sustainability in production.

Powder bonding vs sinter bonding Infographic

libmatt.com

libmatt.com