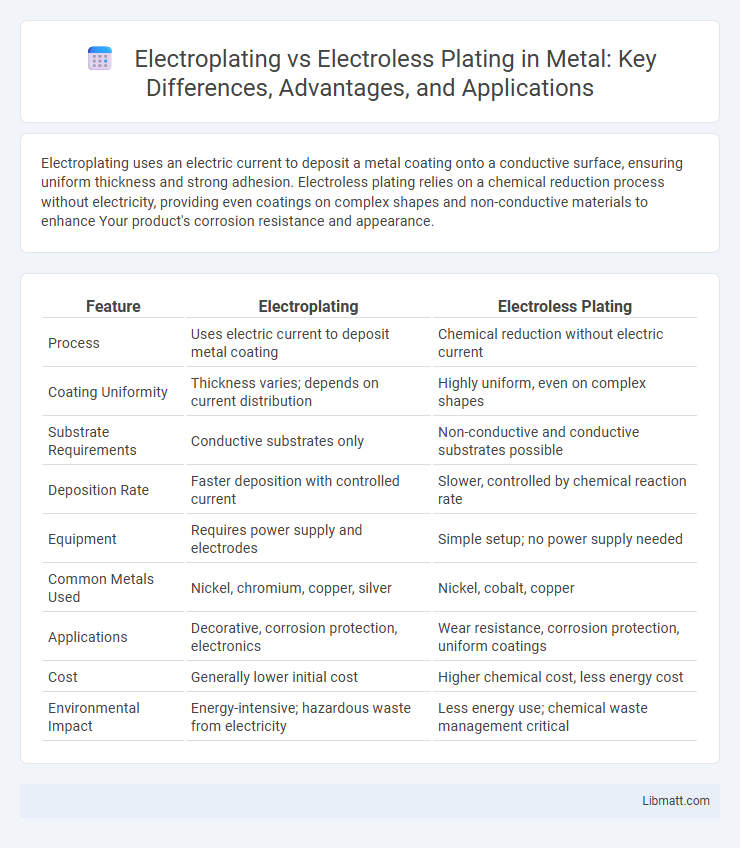

Electroplating uses an electric current to deposit a metal coating onto a conductive surface, ensuring uniform thickness and strong adhesion. Electroless plating relies on a chemical reduction process without electricity, providing even coatings on complex shapes and non-conductive materials to enhance Your product's corrosion resistance and appearance.

Table of Comparison

| Feature | Electroplating | Electroless Plating |

|---|---|---|

| Process | Uses electric current to deposit metal coating | Chemical reduction without electric current |

| Coating Uniformity | Thickness varies; depends on current distribution | Highly uniform, even on complex shapes |

| Substrate Requirements | Conductive substrates only | Non-conductive and conductive substrates possible |

| Deposition Rate | Faster deposition with controlled current | Slower, controlled by chemical reaction rate |

| Equipment | Requires power supply and electrodes | Simple setup; no power supply needed |

| Common Metals Used | Nickel, chromium, copper, silver | Nickel, cobalt, copper |

| Applications | Decorative, corrosion protection, electronics | Wear resistance, corrosion protection, uniform coatings |

| Cost | Generally lower initial cost | Higher chemical cost, less energy cost |

| Environmental Impact | Energy-intensive; hazardous waste from electricity | Less energy use; chemical waste management critical |

Introduction to Electroplating and Electroless Plating

Electroplating relies on an external electric current to deposit a metal coating onto a substrate, enhancing corrosion resistance and aesthetic appeal. Electroless plating, however, uses a chemical reduction process without electricity, allowing for uniform metal layers on complex shapes and non-conductive surfaces. Understanding these fundamental differences helps you choose the appropriate method for your specific coating needs.

Fundamental Principles of Electroplating

Electroplating relies on an external electric current to reduce metal ions from a solution, depositing a thin, uniform metallic coating onto a conductive substrate. This process requires an electrolyte bath, electrodes, and a power source to facilitate ion migration and metal deposition on your workpiece. In contrast, electroless plating uses a chemical reduction reaction without electrical input, making electroplating unique in offering precise control over coating thickness and adhesion through adjustable current parameters.

Core Concepts of Electroless Plating

Electroless plating involves the chemical reduction of metal ions onto a substrate without the use of electrical current, relying on an autocatalytic reaction to deposit a uniform, corrosion-resistant coating. This process allows for consistent thickness on complex geometries and non-conductive surfaces, unlike electroplating which requires an external power source and conductive substrates. Key components in electroless plating baths include a reducing agent, metal salts, complexing agents, and stabilizers to control the deposition rate and metal layer quality.

Key Differences Between Electroplating and Electroless Plating

Electroplating requires an external electric current to reduce metal ions onto a substrate, whereas electroless plating relies on a chemical reduction process without electricity. Electroplating typically produces uniform coatings only on conductive surfaces, while electroless plating can uniformly coat complex shapes and non-conductive materials due to its autocatalytic nature. Thickness control in electroplating depends on current density and plating time, whereas electroless plating achieves consistent thickness through controlled chemical bath composition and temperature.

Advantages of Electroplating

Electroplating offers precise control over coating thickness and uniformity, resulting in enhanced corrosion resistance and improved surface hardness. This method enables efficient metal deposition on complex geometries with minimal waste, making it cost-effective for high-volume production. Your products benefit from superior adhesion and strong metallurgical bonds, which contribute to longer-lasting, durable finishes.

Benefits of Electroless Plating

Electroless plating offers uniform metal deposition on complex shapes without requiring an external power source, ensuring consistent thickness and excellent surface coverage. Its superior corrosion resistance and enhanced hardness improve the durability and wear resistance of your components. This method reduces processing steps and achieves high precision, making it ideal for intricate and high-performance applications.

Applications of Electroplating in Industry

Electroplating is widely used in automotive manufacturing to enhance corrosion resistance and improve aesthetic appeal of car parts. In electronics, it provides conductive coatings to circuit boards and connectors, ensuring reliable electrical performance. Your components benefit from improved wear resistance and durability due to electroplating's precise metal deposition process in industrial applications.

Real-World Uses of Electroless Plating

Electroless plating is widely used in industries requiring uniform metal coatings without electricity, such as automotive, electronics, and aerospace sectors. It provides corrosion resistance, enhanced hardness, and improved wear properties on complex geometries like circuit boards, fuel injector components, and aerospace hardware. The method's ability to deposit metal evenly on non-conductive surfaces and intricate parts makes it indispensable for manufacturing precision components and improving product longevity.

Factors Affecting the Choice of Plating Method

The choice between electroplating and electroless plating depends on factors such as substrate conductivity, desired coating uniformity, and complexity of part geometry. Electroplating requires an electrically conductive surface and provides faster deposition on simpler shapes, whereas electroless plating offers uniform coatings on non-conductive or complex surfaces without the need for external electrical power. Cost considerations, environmental impact, and required corrosion or wear resistance also influence the selection of the plating method.

Future Trends in Plating Technologies

Electroplating advances integrate AI-driven process controls and environmentally friendly, phosphate-free chemistries to enhance coating precision and sustainability. Electroless plating evolves through nanostructured coatings and pulse plating techniques, improving corrosion resistance and uniformity on complex geometries. Emerging hybrid methodologies combine both technologies to capitalize on their respective strengths for next-generation industrial applications.

electroplating vs electroless plating Infographic

libmatt.com

libmatt.com