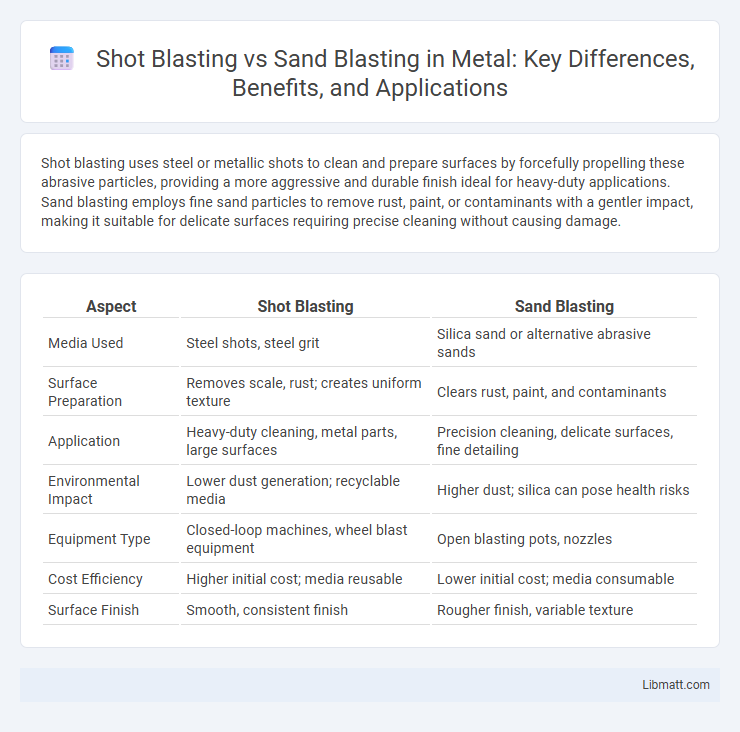

Shot blasting uses steel or metallic shots to clean and prepare surfaces by forcefully propelling these abrasive particles, providing a more aggressive and durable finish ideal for heavy-duty applications. Sand blasting employs fine sand particles to remove rust, paint, or contaminants with a gentler impact, making it suitable for delicate surfaces requiring precise cleaning without causing damage.

Table of Comparison

| Aspect | Shot Blasting | Sand Blasting |

|---|---|---|

| Media Used | Steel shots, steel grit | Silica sand or alternative abrasive sands |

| Surface Preparation | Removes scale, rust; creates uniform texture | Clears rust, paint, and contaminants |

| Application | Heavy-duty cleaning, metal parts, large surfaces | Precision cleaning, delicate surfaces, fine detailing |

| Environmental Impact | Lower dust generation; recyclable media | Higher dust; silica can pose health risks |

| Equipment Type | Closed-loop machines, wheel blast equipment | Open blasting pots, nozzles |

| Cost Efficiency | Higher initial cost; media reusable | Lower initial cost; media consumable |

| Surface Finish | Smooth, consistent finish | Rougher finish, variable texture |

Introduction to Shot Blasting and Sand Blasting

Shot blasting uses high-velocity steel pellets to clean or prepare metal surfaces, providing superior surface finish and enhanced durability. Sand blasting employs abrasive sand particles propelled at high speeds to remove rust, paint, or contaminants, ideal for rough surface preparation. Both methods optimize surface texture for coating adherence but differ in media material, impact force, and environmental considerations.

Core Differences Between Shot Blasting and Sand Blasting

Shot blasting uses steel shots or beads propelled at high velocity to clean or strengthen metal surfaces, while sand blasting employs abrasive sand particles to remove surface contaminants and rust. The core difference lies in their applications: shot blasting is ideal for heavy-duty cleaning and surface preparation with reusability of the abrasive media, whereas sand blasting is better suited for detailed surface etching and finishing but typically requires disposable sand media. Your choice depends on the desired surface finish, material type, and operational efficiency.

Applications and Use Cases

Shot blasting is commonly used for heavy-duty surface preparation in industries such as automotive, aerospace, and construction, effectively removing rust, scale, and old coatings from metal surfaces. Sand blasting is preferred for delicate cleaning tasks, glass etching, and preparing softer materials due to its finer abrasive action and versatility in industrial maintenance and restoration projects. Both methods enhance surface texture and adhesion but are selected based on material sensitivity and desired finish quality.

Advantages of Shot Blasting

Shot blasting offers superior surface cleaning and preparation by using high-velocity steel beads, which enhance metal durability and improve paint adhesion. It produces less dust and waste compared to sand blasting, making it a more environmentally friendly and lower-maintenance option. The process is highly efficient for removing rust, scale, and old coatings, resulting in a consistent and uniform surface finish.

Benefits of Sand Blasting

Sand blasting offers superior surface cleaning by effectively removing rust, paint, and contaminants, enhancing adhesion for coatings and paints. It provides greater control over abrasiveness, making it suitable for delicate surfaces without causing damage. Your project will benefit from faster preparation times and a smoother finish compared to shot blasting.

Material Suitability: Shot Blasting vs Sand Blasting

Shot blasting is ideal for hard, heavy metals like steel and cast iron, providing efficient surface cleaning and preparation by using small steel shots to remove rust and scale. Sand blasting works best on softer materials such as wood, glass, and aluminum, effectively removing paint, corrosion, and contaminants through abrasive sand particles. Your choice between shot blasting and sand blasting should depend on the specific material and desired surface finish to ensure optimal results.

Safety Considerations and Environmental Impact

Shot blasting uses steel or metallic pellets, which pose less respiratory risk compared to the fine silica dust generated by sand blasting, making it a safer option for operator health. The environmental impact of shot blasting is generally lower as it produces less airborne dust and contaminants, while sand blasting can release harmful silica particles that require stringent containment measures. Your choice should weigh these safety and environmental factors to ensure compliance with regulations and protect worker health.

Surface Finish and Quality Comparison

Shot blasting produces a more uniform and consistent surface finish by using steel beads that create a roughened texture ideal for coating adhesion and rust removal. Sand blasting offers a finer, smoother finish due to its abrasive sand particles, making it suitable for delicate surfaces and detailed cleaning. The quality of shot blasting excels in heavy-duty applications requiring durable surface preparation, whereas sand blasting is preferred for precision and aesthetic improvements.

Cost Analysis and Efficiency

Shot blasting offers a higher initial equipment cost compared to sand blasting but results in lower long-term operational expenses due to faster cleaning speeds and reduced abrasive consumption. Sand blasting incurs lower upfront costs but often requires more abrasive material and longer processing times, increasing overall expenses for large-scale projects. Efficiency in shot blasting is enhanced by its ability to clean surfaces uniformly and quickly, making it ideal for industrial applications where cost per unit area is critical.

Choosing the Right Blasting Method for Your Project

Choosing the right blasting method for your project depends on factors like surface type, desired finish, and environmental considerations. Shot blasting uses steel pellets, providing a more aggressive clean for heavy-duty metal surfaces, while sand blasting employs abrasive sand particles ideal for removing rust and paint on various materials. Understanding your project's specific needs ensures optimal results, protecting your equipment and improving surface preparation quality.

Shot blasting vs sand blasting Infographic

libmatt.com

libmatt.com