Die casting involves forcing molten metal under high pressure into a mold, resulting in precise, high-strength parts with excellent surface finish, while gravity casting relies on natural gravity to fill the mold, offering simpler, cost-effective production for larger, less intricate components. You should choose die casting for high-volume, detailed applications and gravity casting for lower-volume or bulky items where simplicity is key.

Table of Comparison

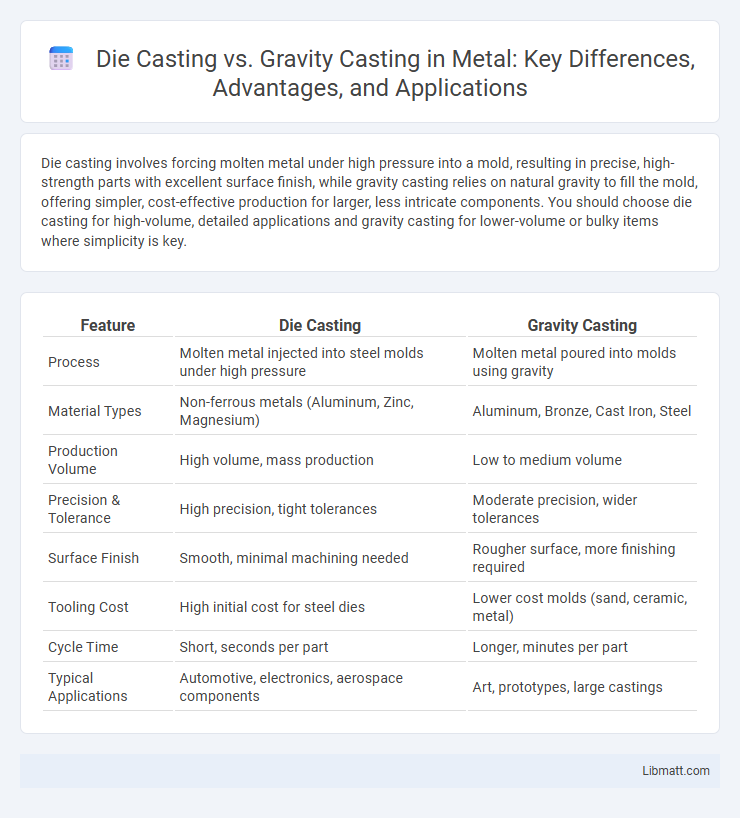

| Feature | Die Casting | Gravity Casting |

|---|---|---|

| Process | Molten metal injected into steel molds under high pressure | Molten metal poured into molds using gravity |

| Material Types | Non-ferrous metals (Aluminum, Zinc, Magnesium) | Aluminum, Bronze, Cast Iron, Steel |

| Production Volume | High volume, mass production | Low to medium volume |

| Precision & Tolerance | High precision, tight tolerances | Moderate precision, wider tolerances |

| Surface Finish | Smooth, minimal machining needed | Rougher surface, more finishing required |

| Tooling Cost | High initial cost for steel dies | Lower cost molds (sand, ceramic, metal) |

| Cycle Time | Short, seconds per part | Longer, minutes per part |

| Typical Applications | Automotive, electronics, aerospace components | Art, prototypes, large castings |

Introduction to Die Casting and Gravity Casting

Die casting uses high-pressure injection of molten metal into steel molds, enabling rapid production of complex, precise parts with superior surface finish and structural integrity. Gravity casting relies on the force of gravity to fill molds, typically using sand or permanent molds, making it suitable for larger, less intricate components with lower tooling costs. Both processes cater to different manufacturing needs based on part complexity, volume, and material properties.

Process Overview: Die Casting vs Gravity Casting

Die casting involves forcing molten metal into a steel mold under high pressure, resulting in precise, high-volume production with excellent surface finish and dimensional accuracy. Gravity casting relies on pouring molten metal into a mold using gravity alone, which is simpler and more cost-effective for low-volume or large, complex parts but may yield less uniformity and surface quality. Your choice between these processes depends on the required production scale, detail complexity, and mechanical properties.

Material Compatibility in Both Methods

Die casting excels in processing non-ferrous metals such as aluminum, magnesium, and zinc alloys due to its high-pressure injection, which ensures fine detail and strength. Gravity casting is compatible with a wider range of materials, including ferrous metals like cast iron and steel, because it uses a slower, low-pressure pour allowing for larger, more complex shapes. Material properties such as melting point and fluidity significantly influence the selection between die casting and gravity casting techniques.

Tooling and Equipment Requirements

Die casting requires high-pressure machines and durable metal molds capable of withstanding rapid injections of molten metal, resulting in substantial upfront tooling costs. Gravity casting utilizes simpler, often reusable sand or metal molds and relies on gravity to fill the mold, leading to lower initial equipment investment but reduced dimensional precision. The choice between die casting and gravity casting tooling hinges on production volume, tolerance demands, and budget constraints.

Differences in Production Speed

Die casting offers significantly faster production speeds compared to gravity casting due to its automated high-pressure process, allowing rapid metal injection and solidification in molds. Gravity casting relies on slower natural flow and solidification under gravity, resulting in longer cycle times and lower throughput. High-volume manufacturing benefits from die casting's efficiency, while gravity casting suits lower volume or larger, complex parts requiring more time.

Cost Comparison: Die Casting vs Gravity Casting

Die casting generally involves higher initial costs due to expensive molds and machinery but offers lower per-unit costs for large production runs, making it cost-effective for high-volume manufacturing. Gravity casting requires less upfront investment with simpler molds, resulting in higher per-unit costs that suit low-volume or custom projects. Your choice depends on balancing these cost factors against production volume and precision requirements.

Quality and Surface Finish

Die casting produces superior quality with precise dimensional accuracy and a smooth, consistent surface finish due to high-pressure injection of molten metal into detailed molds. Gravity casting often results in coarser surfaces and less uniformity, as molten metal flows into the mold relying solely on gravity, leading to potential porosity and surface imperfections. Your choice depends on whether you prioritize high surface finish and intricate detail or cost-effective, simpler production.

Design Flexibility and Complexity

Die casting offers superior design flexibility with the ability to produce complex shapes, intricate details, and thin walls due to high-pressure metal injection into precise molds. Gravity casting, relying on low-pressure metal flow, is limited to simpler geometries and thicker sections, making it less suitable for fine features or highly detailed parts. The enhanced precision and repeatability of die casting enable the creation of complex components with tight tolerances that gravity casting cannot consistently achieve.

Typical Applications and Industries

Die casting excels in high-volume production of complex, thin-walled components commonly used in automotive, aerospace, and electronics industries due to its precision and rapid cycle times. Gravity casting is preferred for manufacturing larger, simpler parts like engine blocks and heavy machinery components in industries such as marine, construction, and industrial equipment because of its ability to produce dense, defect-free castings with minimal pressure. Your choice depends on the required production scale, part complexity, and mechanical properties essential for the target application.

Choosing the Right Casting Method

Choosing the right casting method depends on factors such as production volume, material properties, and desired dimensional accuracy. Die casting offers high precision and fast production rates for metals like aluminum, zinc, and magnesium, making it ideal for large-scale manufacturing. Gravity casting suits lower volume applications and materials with higher melting points, providing simpler tooling and lower initial costs.

die casting vs gravity casting Infographic

libmatt.com

libmatt.com