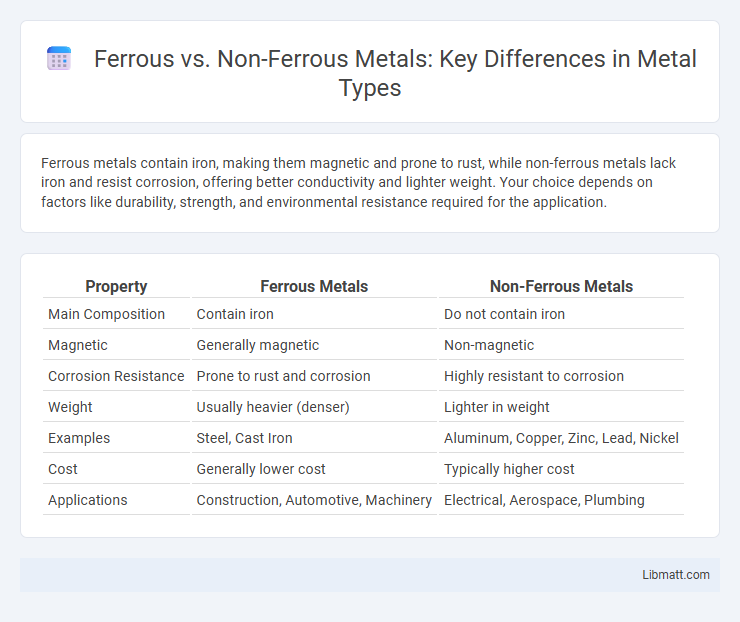

Ferrous metals contain iron, making them magnetic and prone to rust, while non-ferrous metals lack iron and resist corrosion, offering better conductivity and lighter weight. Your choice depends on factors like durability, strength, and environmental resistance required for the application.

Table of Comparison

| Property | Ferrous Metals | Non-Ferrous Metals |

|---|---|---|

| Main Composition | Contain iron | Do not contain iron |

| Magnetic | Generally magnetic | Non-magnetic |

| Corrosion Resistance | Prone to rust and corrosion | Highly resistant to corrosion |

| Weight | Usually heavier (denser) | Lighter in weight |

| Examples | Steel, Cast Iron | Aluminum, Copper, Zinc, Lead, Nickel |

| Cost | Generally lower cost | Typically higher cost |

| Applications | Construction, Automotive, Machinery | Electrical, Aerospace, Plumbing |

Introduction to Ferrous and Non-Ferrous Metals

Ferrous metals contain iron as the primary element, making them magnetic and prone to rust, with common examples including steel and cast iron. Non-ferrous metals lack iron content, offering superior corrosion resistance and lighter weight, such as aluminum, copper, and zinc. These fundamental differences influence their applications in industries like construction, automotive, and electronics due to varying strength, durability, and conductivity properties.

Definition and Key Differences

Ferrous metals contain iron as their primary component, making them magnetic and prone to rust, examples include steel and cast iron. Non-ferrous metals lack iron, exhibit higher resistance to corrosion, and often possess superior conductivity, such as aluminum, copper, and zinc. Key differences lie in magnetic properties, corrosion resistance, weight, and applications across industries like construction, automotive, and electronics.

Common Types of Ferrous Metals

Common types of ferrous metals include carbon steel, cast iron, and stainless steel, each characterized by their iron content and magnetic properties. Carbon steel is widely used in construction and automotive industries due to its strength and affordability. Cast iron offers excellent compressive strength and wear resistance, while stainless steel provides corrosion resistance and is used extensively in medical and food processing equipment.

Popular Non-Ferrous Metals Examples

Popular non-ferrous metals include aluminum, copper, lead, zinc, nickel, and precious metals like gold and silver, known for their corrosion resistance and high conductivity. Unlike ferrous metals, which contain iron, these metals do not rust and are widely used in electrical wiring, plumbing, and aerospace applications. Your choice of non-ferrous metal depends on factors like weight, durability, and specific conductivity needs.

Physical and Chemical Properties Comparison

Ferrous metals contain iron, offering high tensile strength and magnetic properties, while non-ferrous metals lack iron, resulting in enhanced corrosion resistance and non-magnetic qualities. Chemically, ferrous metals tend to oxidize easily, forming rust when exposed to moisture, whereas non-ferrous metals like aluminum and copper exhibit superior chemical stability and resistance to oxidation. Your choice between ferrous and non-ferrous metals depends on the specific physical durability and chemical resistance required for your application.

Applications in Industry and Construction

Ferrous metals, such as steel and cast iron, are extensively used in construction for structural frameworks, bridges, and heavy machinery due to their high strength and durability. Non-ferrous metals like aluminum, copper, and zinc find critical applications in electrical wiring, roofing, and corrosion-resistant components because of their excellent conductivity and resistance to rust. The choice between ferrous and non-ferrous metals in industry depends on factors like mechanical strength, weight, and environmental resistance for optimal performance.

Advantages of Ferrous Metals

Ferrous metals, primarily composed of iron and carbon, offer superior strength, durability, and magnetic properties compared to non-ferrous metals. Their high tensile strength and resistance to wear make them ideal for construction, automotive, and heavy machinery applications. The recyclability and cost-effectiveness of ferrous metals enhance their advantages in large-scale industrial use.

Benefits of Non-Ferrous Metals

Non-ferrous metals offer superior resistance to corrosion, making them ideal for applications exposed to harsh environments such as marine and aerospace industries. They are generally lighter than ferrous metals, enhancing fuel efficiency and ease of handling in manufacturing and construction. Your projects benefit from the excellent electrical conductivity of non-ferrous metals like copper and aluminum, essential for electrical wiring and electronic components.

Recycling and Environmental Impact

Ferrous metals, primarily composed of iron and steel, are highly recyclable and dominate global metal recycling streams due to their magnetic properties, allowing efficient separation and reuse. Non-ferrous metals like aluminum, copper, and zinc, though less abundant, offer significant environmental benefits through recycling by reducing the need for energy-intensive mining and lowering greenhouse gas emissions. Your commitment to recycling both ferrous and non-ferrous metals supports resource conservation and minimizes environmental pollution, promoting sustainable manufacturing practices.

Choosing the Right Metal for Your Project

Selecting the right metal for your project depends on factors such as strength, corrosion resistance, and magnetic properties. Ferrous metals, primarily composed of iron, offer high strength and durability but are prone to rust without proper treatment. Non-ferrous metals like aluminum, copper, and brass provide excellent corrosion resistance, lighter weight, and non-magnetic properties, making them ideal for applications requiring longevity and reduced weight.

ferrous vs non ferrous metals Infographic

libmatt.com

libmatt.com