Pack carburizing involves placing steel parts in a sealed container filled with carbon-rich material, allowing carbon to diffuse into the surface at high temperatures, producing a hard, wear-resistant layer. Gas carburizing uses a carbonaceous gas atmosphere to introduce carbon into the steel surface, offering better control over case depth and surface finish for your precision components.

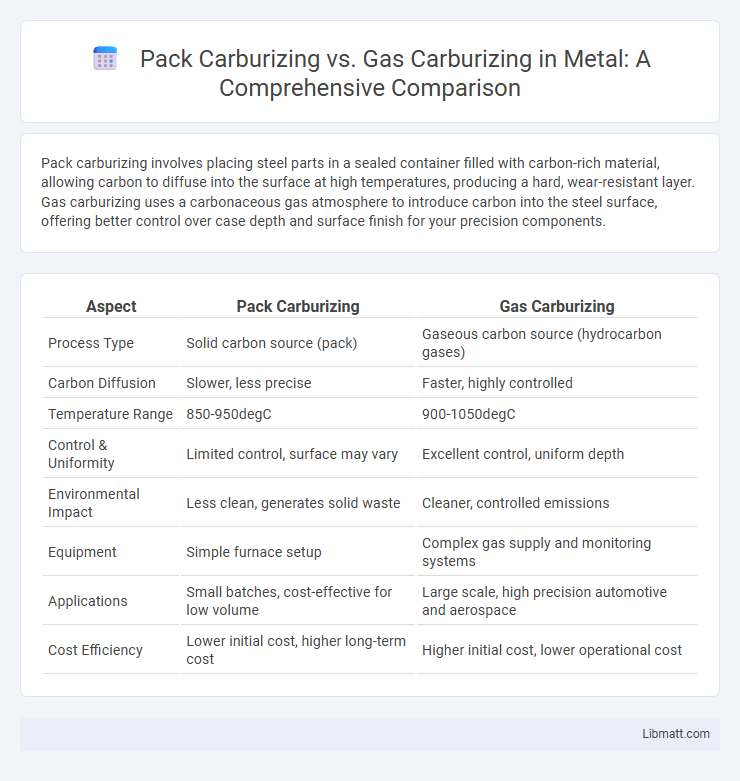

Table of Comparison

| Aspect | Pack Carburizing | Gas Carburizing |

|---|---|---|

| Process Type | Solid carbon source (pack) | Gaseous carbon source (hydrocarbon gases) |

| Carbon Diffusion | Slower, less precise | Faster, highly controlled |

| Temperature Range | 850-950degC | 900-1050degC |

| Control & Uniformity | Limited control, surface may vary | Excellent control, uniform depth |

| Environmental Impact | Less clean, generates solid waste | Cleaner, controlled emissions |

| Equipment | Simple furnace setup | Complex gas supply and monitoring systems |

| Applications | Small batches, cost-effective for low volume | Large scale, high precision automotive and aerospace |

| Cost Efficiency | Lower initial cost, higher long-term cost | Higher initial cost, lower operational cost |

Introduction to Carburizing Processes

Pack carburizing uses solid carbon materials such as charcoal or carbon-rich powders packed around steel parts, facilitating carbon diffusion at high temperatures to enhance surface hardness. Gas carburizing employs a carbon-rich gas atmosphere, typically methane or propane, allowing precise control over carbon potential and case depth through continuous gas flow and temperature regulation. Both methods aim to improve wear resistance and fatigue strength by creating a hardened surface layer, but gas carburizing offers greater process control and efficiency for industrial applications.

Overview of Pack Carburizing

Pack carburizing is a heat treatment process where steel parts are embedded in a carbon-rich solid compound and heated in a sealed retort to diffuse carbon into the surface. This method effectively increases surface hardness and wear resistance through a controlled carbon transfer, making it suitable for complex shapes and heavy components. Compared to gas carburizing, pack carburizing typically operates at lower costs but requires longer processing times and more post-treatment cleaning.

Overview of Gas Carburizing

Gas carburizing is a heat treatment process that enhances surface hardness and wear resistance by introducing carbon into the steel's surface using carbon-rich gases such as methane or propane. Unlike pack carburizing, where the metal is embedded in carbonaceous material, gas carburizing offers precise control of carbon potential and temperature, resulting in uniform case depth and minimal distortion. This method is widely used in automotive and aerospace industries for components like gears and shafts requiring improved fatigue life and surface durability.

Key Differences Between Pack and Gas Carburizing

Pack carburizing involves embedding parts in a carbon-rich solid medium at high temperatures, while gas carburizing uses a carbon-containing gas atmosphere to diffuse carbon into the metal surface. Pack carburizing typically offers deeper carbon penetration and is better suited for complex shapes, whereas gas carburizing allows more precise control over carbon potential and surface hardness. Gas carburizing is generally faster and cleaner, making it favorable for mass production with consistent results.

Process Parameters of Pack Carburizing

Pack carburizing involves placing a steel component into a sealed container filled with carbon-rich solid media, heated typically between 900degC to 950degC, where the carbon diffuses into the surface. Key process parameters include temperature control, carburizing time ranging from 1 to 24 hours depending on desired case depth, and the composition of the carbonaceous pack material, which directly influence carbon potential and case uniformity. Your choice of pack carburizing parameters impacts surface hardness, wear resistance, and case depth, making precise control critical for optimal performance.

Process Parameters of Gas Carburizing

Gas carburizing involves heating the workpiece in a controlled atmosphere containing carbon-rich gases like methane, propane, or natural gas, typically at temperatures between 900degC and 950degC. The carbon potential of the gas atmosphere is carefully regulated to ensure proper diffusion of carbon into the steel surface, enhancing hardness and wear resistance. Your choice of gas flow rate, carburizing time, and temperature directly influences case depth and uniformity compared to the more batch-oriented and less controllable pack carburizing process.

Advantages of Pack Carburizing

Pack carburizing offers superior control over carbon diffusion, resulting in a deeper and more uniform case hardening compared to gas carburizing. This method is cost-effective and does not require complex equipment or gas supplies, making it ideal for small batches and maintenance work. Your components benefit from enhanced surface hardness and wear resistance without the risk of decarburization often associated with gas carburizing processes.

Benefits of Gas Carburizing

Gas carburizing offers superior control over carbon concentration and depth, resulting in more uniform and consistent case hardening compared to pack carburizing. This method reduces environmental waste and improves efficiency by using controlled atmospheres instead of solid carburizing agents. Enhanced surface quality and shorter processing times make gas carburizing a preferred choice for high-precision industrial applications.

Applications and Industry Use Cases

Pack carburizing is widely employed in heavy-duty applications such as gears, crankshafts, and other large steel components requiring deep case hardening, commonly found in automotive and heavy machinery industries. Gas carburizing offers more precise control over carbon diffusion, making it ideal for aerospace components, tooling, and smaller parts demanding uniform surface hardness and dimensional accuracy. Your choice between pack and gas carburizing depends on the specific industry requirements for case depth, component size, and production volume.

Choosing the Right Carburizing Method

Choosing the right carburizing method depends on factors like part size, complexity, and desired surface hardness. Pack carburizing offers deep, uniform case depth ideal for small batches and complex shapes, while gas carburizing provides precise control, faster processing, and cleaner surfaces for larger production runs. Understanding your specific metallurgical requirements ensures Your components achieve optimal wear resistance and durability.

pack carburizing vs gas carburizing Infographic

libmatt.com

libmatt.com