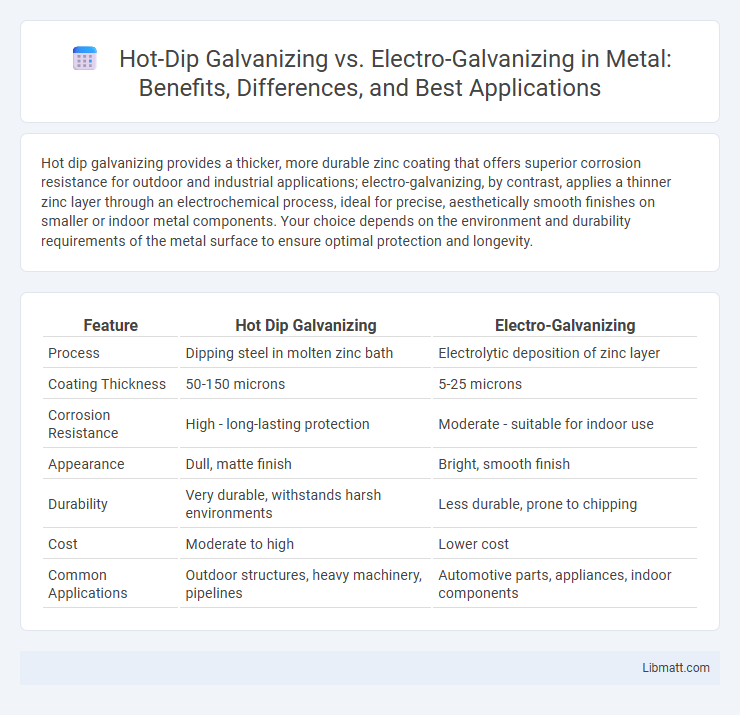

Hot dip galvanizing provides a thicker, more durable zinc coating that offers superior corrosion resistance for outdoor and industrial applications; electro-galvanizing, by contrast, applies a thinner zinc layer through an electrochemical process, ideal for precise, aesthetically smooth finishes on smaller or indoor metal components. Your choice depends on the environment and durability requirements of the metal surface to ensure optimal protection and longevity.

Table of Comparison

| Feature | Hot Dip Galvanizing | Electro-Galvanizing |

|---|---|---|

| Process | Dipping steel in molten zinc bath | Electrolytic deposition of zinc layer |

| Coating Thickness | 50-150 microns | 5-25 microns |

| Corrosion Resistance | High - long-lasting protection | Moderate - suitable for indoor use |

| Appearance | Dull, matte finish | Bright, smooth finish |

| Durability | Very durable, withstands harsh environments | Less durable, prone to chipping |

| Cost | Moderate to high | Lower cost |

| Common Applications | Outdoor structures, heavy machinery, pipelines | Automotive parts, appliances, indoor components |

Introduction to Galvanizing Processes

Hot dip galvanizing involves immersing steel in molten zinc at approximately 450degC, creating a robust, corrosion-resistant coating through metallurgical bonding. Electro-galvanizing uses an electric current to deposit a thin zinc layer onto steel, resulting in a smooth, uniform finish ideal for automotive and appliance industries. Both processes enhance steel durability but differ in coating thickness, adhesion, and suitability for various environmental conditions.

What is Hot Dip Galvanizing?

Hot Dip Galvanizing is a corrosion protection process where steel is submerged in molten zinc at approximately 450degC, forming a robust metallurgical bond. This coating provides superior durability and resistance against rust, making it ideal for outdoor and industrial applications. The thick, zinc layer created enhances longevity, outperforming thinner coatings like those from electro-galvanizing.

What is Electro-Galvanizing?

Electro-galvanizing is a metal coating process that uses electrical current to deposit a thin layer of zinc onto the surface of steel or iron, enhancing corrosion resistance. This method produces a smooth, uniform finish ideal for automotive parts, appliances, and electronic components requiring precise thickness control. Your choice of electro-galvanizing ensures improved paint adhesion and a sleek appearance compared to traditional coating techniques.

Key Differences Between Hot Dip and Electro-Galvanizing

Hot dip galvanizing involves immersing steel in molten zinc, creating a thick, durable coating that offers superior corrosion resistance and is ideal for outdoor and industrial applications. Electro-galvanizing uses an electrical current to deposit a thin zinc layer, providing a smoother finish but less protection against corrosion, making it suited for indoor or less demanding environments. The key differences include coating thickness, durability, corrosion resistance, surface finish, and application suitability.

Comparative Corrosion Resistance

Hot dip galvanizing provides superior corrosion resistance compared to electro-galvanizing due to its thicker zinc coating that forms a robust barrier against moisture and environmental elements. Electro-galvanizing offers a thinner, more uniform zinc layer ideal for indoor use or applications requiring a smoother finish but typically corrodes faster in harsh conditions. Your choice between these methods should consider the specific environmental exposure and durability requirements to ensure optimal long-term protection.

Surface Finish and Appearance

Hot dip galvanizing produces a thick, rough, and matte zinc coating with a slightly uneven surface finish that offers robust corrosion resistance and a rugged appearance. Electro-galvanizing yields a thinner, smoother, and shinier zinc layer, providing a uniform, aesthetically pleasing surface ideal for decorative applications. The choice between these methods depends on the desired balance between durability and visual appeal, with hot dip favored for heavy-duty protection and electro-galvanizing preferred for a polished look.

Cost Considerations: Hot Dip vs Electro-Galvanizing

Hot dip galvanizing generally incurs higher initial costs compared to electro-galvanizing due to the intense heating process and thicker zinc coating applied. Your choice depends on budget constraints and the required corrosion resistance, with hot dip galvanizing providing longer-lasting protection at a premium price. Electro-galvanizing offers a more cost-effective solution for applications with moderate exposure to corrosive environments.

Application Suitability and Industry Use

Hot dip galvanizing offers superior corrosion resistance and is ideal for heavy-duty applications such as construction, automotive, and infrastructure where long-term protection is critical. Electro-galvanizing provides a thinner, more uniform coating suited for precision components in electronics, appliances, and automotive interiors where appearance and dimensional accuracy are key. Your choice between these galvanizing methods depends on the durability requirements and environmental exposure of the industry application.

Durability and Maintenance Requirements

Hot dip galvanizing provides superior durability with a thick zinc coating that resists corrosion and mechanical damage, making it ideal for outdoor and industrial applications. Electro-galvanizing offers a thinner zinc layer, which provides adequate corrosion resistance in less demanding environments but requires more frequent maintenance and touch-ups. Maintenance for hot dip galvanized steel is minimal due to its robust protective layer, whereas electro-galvanized steel surfaces often need regular inspection and occasional re-coating to prevent rust.

Choosing the Right Galvanizing Method

Choosing the right galvanizing method depends on factors such as corrosion resistance, coating thickness, and application environment. Hot dip galvanizing offers a thicker, more durable zinc coating ideal for outdoor or industrial use, while electro-galvanizing provides a smoother finish suited for indoor applications requiring precise dimensions. Understanding your project's exposure and durability needs ensures you select the most effective galvanizing technique for long-lasting protection.

Hot Dip Galvanizing vs Electro-Galvanizing Infographic

libmatt.com

libmatt.com