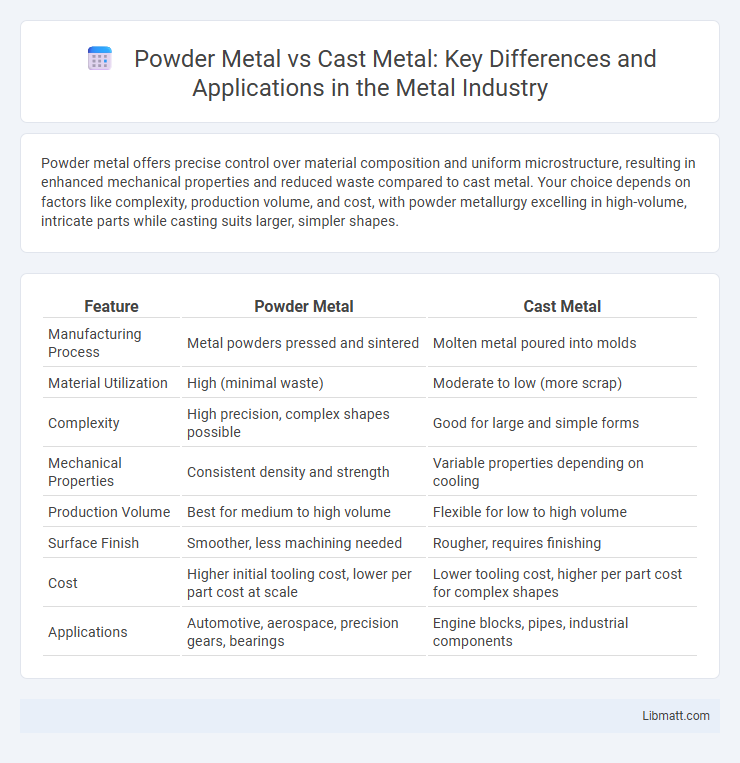

Powder metal offers precise control over material composition and uniform microstructure, resulting in enhanced mechanical properties and reduced waste compared to cast metal. Your choice depends on factors like complexity, production volume, and cost, with powder metallurgy excelling in high-volume, intricate parts while casting suits larger, simpler shapes.

Table of Comparison

| Feature | Powder Metal | Cast Metal |

|---|---|---|

| Manufacturing Process | Metal powders pressed and sintered | Molten metal poured into molds |

| Material Utilization | High (minimal waste) | Moderate to low (more scrap) |

| Complexity | High precision, complex shapes possible | Good for large and simple forms |

| Mechanical Properties | Consistent density and strength | Variable properties depending on cooling |

| Production Volume | Best for medium to high volume | Flexible for low to high volume |

| Surface Finish | Smoother, less machining needed | Rougher, requires finishing |

| Cost | Higher initial tooling cost, lower per part cost at scale | Lower tooling cost, higher per part cost for complex shapes |

| Applications | Automotive, aerospace, precision gears, bearings | Engine blocks, pipes, industrial components |

Introduction to Powder Metal and Cast Metal

Powder metal is produced by compressing and sintering metal powders, resulting in precise shapes with minimal waste, enhanced strength, and excellent material utilization. Cast metal involves melting metal alloys and pouring them into molds, allowing complex geometries but often requiring additional machining due to shrinkage and porosity. Powder metallurgy is ideal for high-volume production with tight tolerances, while casting suits larger, intricate components where design flexibility is paramount.

Overview of Manufacturing Processes

Powder metal manufacturing involves compressing metal powders into desired shapes followed by sintering at high temperatures to bond particles, enabling precise control of microstructure and minimal material waste. Cast metal processing melts metal alloys and pours them into molds where the metal solidifies, allowing for complex geometries but often resulting in coarser grain structures and potential porosity. Powder metallurgy provides improved mechanical properties and dimensional accuracy compared to traditional casting methods due to finer microstructures and reduced defects.

Material Properties Comparison

Powder metal exhibits superior uniformity in microstructure and reduced porosity compared to cast metal, resulting in enhanced mechanical properties such as increased tensile strength and wear resistance. Cast metal often contains larger grain sizes and potential defects like shrinkage cavities, which can compromise durability and fatigue performance. By selecting powder metal for your components, you can achieve consistent material properties tailored to high-performance applications.

Strength and Durability Differences

Powder metal components exhibit superior uniformity and fewer defects compared to cast metal, resulting in enhanced strength and durability under cyclic loads. Cast metals often contain porosity and inclusions that can act as stress concentrators, reducing fatigue resistance and long-term performance. Understanding these differences helps you select the optimal material for applications requiring high mechanical reliability.

Design Flexibility and Complexity

Powder metal manufacturing enables superior design flexibility by allowing intricate geometries, fine details, and complex internal structures that are difficult to achieve with traditional casting. This technique supports high precision and near-net-shape production, minimizing the need for machining and reducing material waste. In contrast, cast metal often faces limitations in forming complex shapes due to mold constraints and shrinkage issues, restricting the design complexity achievable in a single piece.

Cost Efficiency and Scalability

Powder metal manufacturing offers superior cost efficiency for complex, high-volume parts due to minimal material waste and reduced machining requirements compared to cast metal processes. Scalability in powder metal production is enhanced by its ability to produce consistent parts with tight tolerances in large quantities, whereas cast metal may face limitations due to mold costs and longer cycle times. Your choice between these methods should consider volume needs and budget constraints to maximize production efficiency.

Applications in Various Industries

Powder metal excels in producing complex shapes with high precision, making it ideal for the automotive, aerospace, and medical industries where intricate components like gears, implants, and turbine blades are essential. Cast metal offers advantages in large-scale manufacturing of heavy-duty parts such as engine blocks, pipes, and machinery components used extensively in construction, shipping, and energy sectors. Your choice between powder metal and cast metal depends on the required mechanical properties, production volume, and cost-efficiency for specific industrial applications.

Environmental Impact and Sustainability

Powder metal manufacturing significantly reduces material waste by utilizing near-net shaping processes, whereas cast metal production often generates excess scrap and requires more energy-intensive melting. Your choice of powder metal can lower greenhouse gas emissions due to its energy-efficient sintering techniques and reduced material consumption. Sustainable manufacturing benefits from powder technology's ability to recycle metal powders and minimize environmental pollution compared to traditional casting methods.

Quality Control and Consistency

Powder metal offers superior quality control and consistency compared to cast metal, as its manufacturing process involves precise blending, compaction, and sintering of metal powders that reduce defects and ensure uniform microstructure. Cast metal, while versatile, is more prone to internal porosity and variability in grain structure due to cooling rates and mold design, leading to potential inconsistencies in mechanical properties. Your choice of powder metal can result in more reliable performance and tighter dimensional tolerances for high-precision applications.

Choosing Between Powder Metal and Cast Metal

Choosing between powder metal and cast metal depends on the specific application requirements, including material properties, production volume, and cost efficiency. Powder metal offers superior precision, reduced waste, and enhanced mechanical properties, making it ideal for complex shapes and high-performance applications. Cast metal is typically better suited for large, robust components where lower initial tooling costs and versatility in alloy selection are prioritized.

powder metal vs cast metal Infographic

libmatt.com

libmatt.com