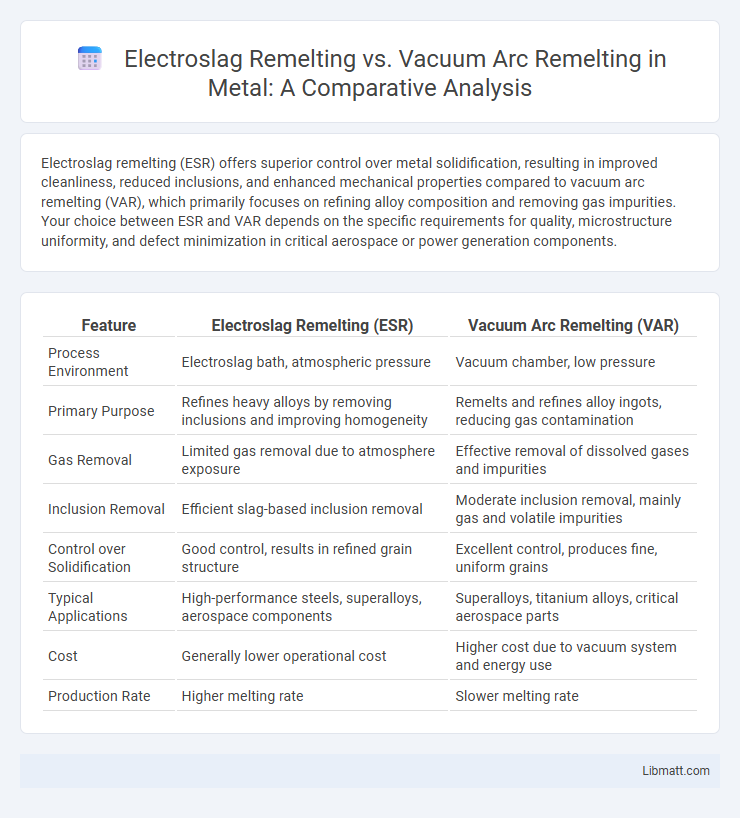

Electroslag remelting (ESR) offers superior control over metal solidification, resulting in improved cleanliness, reduced inclusions, and enhanced mechanical properties compared to vacuum arc remelting (VAR), which primarily focuses on refining alloy composition and removing gas impurities. Your choice between ESR and VAR depends on the specific requirements for quality, microstructure uniformity, and defect minimization in critical aerospace or power generation components.

Table of Comparison

| Feature | Electroslag Remelting (ESR) | Vacuum Arc Remelting (VAR) |

|---|---|---|

| Process Environment | Electroslag bath, atmospheric pressure | Vacuum chamber, low pressure |

| Primary Purpose | Refines heavy alloys by removing inclusions and improving homogeneity | Remelts and refines alloy ingots, reducing gas contamination |

| Gas Removal | Limited gas removal due to atmosphere exposure | Effective removal of dissolved gases and impurities |

| Inclusion Removal | Efficient slag-based inclusion removal | Moderate inclusion removal, mainly gas and volatile impurities |

| Control over Solidification | Good control, results in refined grain structure | Excellent control, produces fine, uniform grains |

| Typical Applications | High-performance steels, superalloys, aerospace components | Superalloys, titanium alloys, critical aerospace parts |

| Cost | Generally lower operational cost | Higher cost due to vacuum system and energy use |

| Production Rate | Higher melting rate | Slower melting rate |

Introduction to Remelting Technologies

Electroslag remelting (ESR) and vacuum arc remelting (VAR) are advanced metallurgical processes used to improve the purity and mechanical properties of high-performance alloys. ESR utilizes a molten slag to purify metal by remelting an electrode under controlled conditions, reducing non-metallic inclusions and enhancing homogeneity. VAR operates in a vacuum environment where an electric arc remelts the electrode, minimizing gas contamination and ensuring superior cleanliness and structural integrity in aerospace and nuclear-grade superalloys.

Overview of Electroslag Remelting (ESR)

Electroslag Remelting (ESR) is a secondary melting process primarily used to refine steel and superalloys, improving their purity, microstructure, and mechanical properties by controlled solidification under a molten slag. The ESR process reduces inclusions and homogenizes the composition, resulting in enhanced cleanliness and superior fatigue resistance compared to traditional remelting methods. Your choice of ESR for critical applications ensures improved material performance, especially in aerospace, power generation, and high-stress engineering components.

Overview of Vacuum Arc Remelting (VAR)

Vacuum Arc Remelting (VAR) is a secondary melting process that refines metals by remelting an electrode under a controlled vacuum atmosphere to reduce impurities and improve alloy homogeneity. VAR enhances the mechanical properties and cleanliness of high-performance alloys, such as titanium, stainless steel, and superalloys, by minimizing gas absorption and segregation defects. Your choice of VAR ensures superior ingot quality for critical aerospace, medical, and power generation applications requiring precise metallurgical control.

Key Differences Between ESR and VAR

Electroslag Remelting (ESR) uses a molten slag pool to refine metal, producing a clean, dense ingot with improved chemical homogeneity and reduced inclusion content. Vacuum Arc Remelting (VAR) operates under a vacuum to minimize gas contamination, enhancing metal purity and controlling solidification structure for better mechanical properties. Your choice depends on the specific requirements for inclusion control, chemical uniformity, and material performance in critical applications.

Metallurgical Advantages of ESR

Electroslag remelting (ESR) provides superior metallurgical benefits by producing ingots with refined microstructures, reduced segregation, and minimized impurities compared to vacuum arc remelting (VAR). ESR achieves a more uniform grain size and improved cleanliness due to the controlled slag environment, which filters out non-metallic inclusions and promotes better solidification conditions. These advantages result in enhanced mechanical properties and corrosion resistance for critical aerospace and high-performance components.

Metallurgical Advantages of VAR

Vacuum arc remelting (VAR) offers superior control over metal cleanliness and solidification due to its vacuum environment, significantly reducing gas contamination and inclusions compared to electroslag remelting (ESR). This process enhances the mechanical properties and homogeneity of high-performance alloys, making VAR ideal for aerospace and medical applications requiring stringent metallurgical standards. Your components benefit from refined microstructures and improved toughness, ensuring reliability in critical service conditions.

Applications of Electroslag Remelting

Electroslag Remelting (ESR) is widely employed in the production of high-quality steel and superalloys used in aerospace, turbine components, and heavy machinery where enhanced purity and uniformity are essential. This process is particularly valuable for manufacturing large structural parts and components exposed to extreme mechanical stress and high temperatures. Your choice of ESR ensures superior cleanliness and reduced segregation, leading to improved mechanical properties and longer service life.

Applications of Vacuum Arc Remelting

Vacuum Arc Remelting (VAR) is widely applied in aerospace, medical implants, and nuclear industries due to its ability to produce ultra-clean, high-purity metal alloys with homogeneous microstructures. This process is essential for manufacturing superalloys, titanium, and specialty steels where superior mechanical properties and reduced impurities are critical. Your components benefit from VAR's precise control over solidification, minimizing defects and ensuring enhanced performance in demanding environments.

Cost Implications: ESR vs. VAR

Electroslag Remelting (ESR) typically incurs higher operational costs due to its energy-intensive slag melting process and the requirement for specialized equipment. Vacuum Arc Remelting (VAR) often presents lower initial investment expenses but can have increased maintenance costs related to vacuum system components and electrode preparation. Cost-efficiency depends on production volume and material quality requirements, with ESR favored for high-performance alloys demanding superior cleanliness and uniformity despite its higher price point.

Choosing the Optimal Remelting Process

Electroslag remelting (ESR) and vacuum arc remelting (VAR) are advanced metallurgical processes used to enhance the purity and mechanical properties of specialty alloys. ESR excels in producing large ingots with improved chemical homogeneity and reduced inclusion levels, while VAR is particularly effective in removing gas impurities and achieving ultra-clean steel with precise control over solidification. Choosing the optimal remelting process depends on your alloy composition, desired material properties, and specific application requirements, balancing factors such as cost, scale, and impurity control.

Electroslag remelting vs vacuum arc remelting Infographic

libmatt.com

libmatt.com