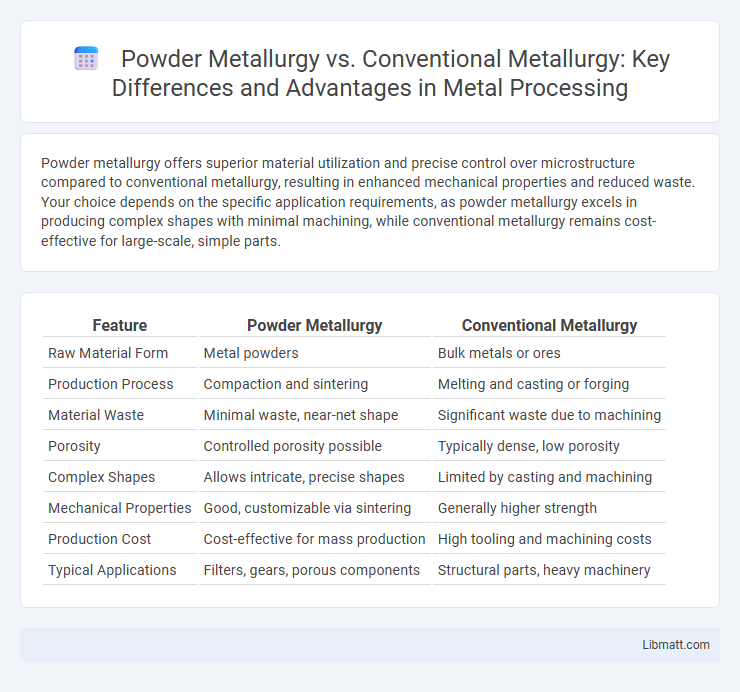

Powder metallurgy offers superior material utilization and precise control over microstructure compared to conventional metallurgy, resulting in enhanced mechanical properties and reduced waste. Your choice depends on the specific application requirements, as powder metallurgy excels in producing complex shapes with minimal machining, while conventional metallurgy remains cost-effective for large-scale, simple parts.

Table of Comparison

| Feature | Powder Metallurgy | Conventional Metallurgy |

|---|---|---|

| Raw Material Form | Metal powders | Bulk metals or ores |

| Production Process | Compaction and sintering | Melting and casting or forging |

| Material Waste | Minimal waste, near-net shape | Significant waste due to machining |

| Porosity | Controlled porosity possible | Typically dense, low porosity |

| Complex Shapes | Allows intricate, precise shapes | Limited by casting and machining |

| Mechanical Properties | Good, customizable via sintering | Generally higher strength |

| Production Cost | Cost-effective for mass production | High tooling and machining costs |

| Typical Applications | Filters, gears, porous components | Structural parts, heavy machinery |

Introduction to Powder Metallurgy and Conventional Metallurgy

Powder metallurgy involves producing metal components by compacting metal powders into desired shapes and sintering them at high temperatures, offering precise control over material properties and minimal waste. Conventional metallurgy relies on melting and casting metals, followed by shaping through forging, rolling, or machining, which often leads to higher energy consumption and material loss. Powder metallurgy excels in creating complex geometries with superior material homogeneity compared to conventional melting and forming techniques.

Fundamental Differences Between Powder and Conventional Metallurgy

Powder metallurgy involves producing metal parts by compacting and sintering powdered materials, whereas conventional metallurgy relies on melting and casting or forging solid metal. The fundamental difference lies in the process phases: powder metallurgy offers precise control over composition and microstructure, enabling near-net shape manufacturing with minimal waste. Your choice between these methods depends on factors like part complexity, material properties, and production volume.

Raw Materials and Processing Techniques

Powder metallurgy utilizes finely powdered metals as raw materials, allowing precise control over alloy composition and minimal material waste through sintering and compaction processes. Conventional metallurgy relies on bulk raw metals, typically requiring melting, casting, and forging, which lead to higher energy consumption and potential material loss. Powder metallurgy's specialized processing techniques enable the production of complex shapes with enhanced mechanical properties, contrasting the more straightforward shaping methods in conventional metallurgy.

Manufacturing Process Steps Comparison

Powder metallurgy involves powder production, compaction, and sintering, enabling precise control over material composition and minimal machining requirements. Conventional metallurgy typically includes melting, casting, forging, and machining, which can lead to more material waste and longer processing times. The powder metallurgy process allows for near-net-shape manufacturing, reducing secondary operations compared to the multi-stage deformation and shaping steps in conventional metallurgy.

Material Properties and Performance Outcomes

Powder metallurgy offers superior control over material properties such as porosity, hardness, and wear resistance compared to conventional metallurgy, resulting in enhanced performance outcomes like improved strength-to-weight ratios and tailored microstructures. Conventional metallurgy typically involves melting and casting processes that can lead to grain growth and segregation, affecting uniformity and mechanical properties. Your choice between these methods impacts the final component's durability, precision, and suitability for high-performance applications.

Design Flexibility and Complexity

Powder metallurgy offers superior design flexibility and complexity compared to conventional metallurgy due to its ability to produce intricate shapes and detailed geometries with minimal material waste. This process enables the fabrication of components with tailored porosity, controlled microstructures, and precise dimensions that are difficult to achieve through traditional casting or forging methods. Your manufacturing requirements benefit from powder metallurgy's capacity to create complex parts efficiently, reducing the need for extensive machining and assembly.

Cost Efficiency and Economic Considerations

Powder metallurgy offers significant cost efficiency through reduced material waste, lower energy consumption, and the ability to produce complex parts in near-net shapes, minimizing machining expenses. Conventional metallurgy often requires extensive machining and material removal, increasing labor and production costs, especially for intricate designs. Economic considerations favor powder metallurgy for high-volume production runs where consistent quality and minimal post-processing reduce overall manufacturing costs.

Environmental Impact and Sustainability

Powder metallurgy significantly reduces material wastage by using nearly 100% of metal powders, contrasting with the substantial scrap generated in conventional metallurgy processes. Your choice of powder metallurgy can lower energy consumption by up to 40% due to lower melting and processing temperatures, contributing to a smaller carbon footprint. Sustainable manufacturing is enhanced by powder metallurgy's ability to recycle powders and minimize emissions, aligning with eco-friendly production goals.

Common Applications and Industry Use Cases

Powder metallurgy excels in producing complex, high-precision components for automotive gears, aerospace turbine blades, and medical implants, benefiting industries requiring lightweight, high-strength parts with minimal material waste. Conventional metallurgy remains dominant in large-scale construction, shipbuilding, and heavy machinery manufacturing where bulk metal products like steel beams and structural components are essential. Both methods complement industrial needs by balancing cost, material properties, and production efficiency across diverse sectors.

Advantages and Limitations of Each Method

Powder metallurgy offers advantages such as precise control over material composition, reduced waste, and the ability to create complex shapes with minimal machining. However, it faces limitations including higher initial tooling costs and lower mechanical strength compared to conventional metallurgy. Conventional metallurgy provides superior mechanical properties and is cost-effective for large-scale production but involves more material waste and requires extensive machining for intricate components.

powder metallurgy vs conventional metallurgy Infographic

libmatt.com

libmatt.com