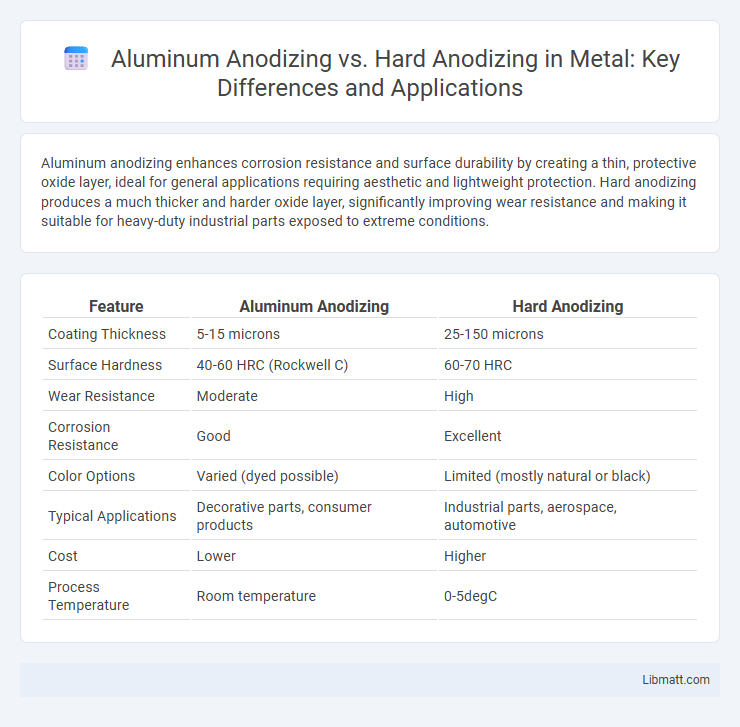

Aluminum anodizing enhances corrosion resistance and surface durability by creating a thin, protective oxide layer, ideal for general applications requiring aesthetic and lightweight protection. Hard anodizing produces a much thicker and harder oxide layer, significantly improving wear resistance and making it suitable for heavy-duty industrial parts exposed to extreme conditions.

Table of Comparison

| Feature | Aluminum Anodizing | Hard Anodizing |

|---|---|---|

| Coating Thickness | 5-15 microns | 25-150 microns |

| Surface Hardness | 40-60 HRC (Rockwell C) | 60-70 HRC |

| Wear Resistance | Moderate | High |

| Corrosion Resistance | Good | Excellent |

| Color Options | Varied (dyed possible) | Limited (mostly natural or black) |

| Typical Applications | Decorative parts, consumer products | Industrial parts, aerospace, automotive |

| Cost | Lower | Higher |

| Process Temperature | Room temperature | 0-5degC |

Introduction to Aluminum Anodizing

Aluminum anodizing enhances the metal's surface by creating a durable oxide layer that improves corrosion resistance, wear resistance, and aesthetic appeal. Standard anodizing produces a thinner, decorative coating ideal for everyday applications, while hard anodizing forms a thicker, harder layer suited for demanding industrial uses. Understanding the differences helps you select the best anodizing process to meet your aluminum's performance and durability requirements.

What is Hard Anodizing?

Hard anodizing is an advanced electrochemical process that significantly increases the thickness and hardness of the aluminum oxide layer on aluminum surfaces, producing a durable, wear-resistant coating typically ranging from 25 to 150 microns thick. Unlike standard aluminum anodizing, which forms a thinner and more decorative oxide layer, hard anodizing provides enhanced corrosion resistance, improved abrasion resistance, and superior thermal conductivity, making it ideal for industrial applications such as aerospace, automotive, and heavy machinery. The resulting surface is harder than steel, capable of withstanding extreme conditions while maintaining the metal's lightweight advantages.

Key Differences Between Standard and Hard Anodizing

Standard aluminum anodizing creates a thin oxide layer primarily for corrosion resistance and aesthetic enhancement, while hard anodizing produces a much thicker, denser oxide coating that significantly improves wear resistance and surface hardness. The temperature and voltage conditions differ, with hard anodizing requiring lower temperatures and higher voltages to achieve the robust, durable finish ideal for heavy-duty applications. Your choice depends on whether you need enhanced protection and durability or just a standard protective and decorative layer on aluminum surfaces.

Process Overview: Aluminum Anodizing

Aluminum anodizing is an electrochemical process that converts the metal surface into a durable, corrosion-resistant oxide layer through controlled oxidation. This process enhances aluminum's natural oxide barrier, increasing wear resistance and providing a porous surface ideal for dye absorption. Hard anodizing, a subtype of aluminum anodizing, uses lower temperatures and higher current densities to create a thicker, denser oxide layer suitable for heavy-duty applications.

Process Details: Hard Anodizing Explained

Hard anodizing involves an electrochemical process that thickens the natural oxide layer on aluminum, typically producing a coating thickness of 25 to 150 microns, compared to standard anodizing's 5 to 25 microns. This results in a denser, harder surface with increased wear and corrosion resistance, ideal for industrial applications requiring high durability. Your projects benefit from hard anodizing's enhanced protection and longer lifespan under extreme conditions.

Thickness and Durability Comparison

Hard anodizing creates a significantly thicker oxide layer, typically ranging from 25 to 150 microns, compared to standard aluminum anodizing which generally produces a layer between 5 to 25 microns. This increased thickness in hard anodizing enhances durability, providing superior resistance to wear, abrasion, and corrosion, making it ideal for heavy-duty applications. Standard anodizing offers adequate protection for everyday use but lacks the robustness required for extreme environmental and mechanical stresses.

Surface Finish and Appearance

Aluminum anodizing typically produces a smooth, consistent surface finish with a natural metallic sheen, enhancing corrosion resistance while allowing for vibrant dye penetration. Hard anodizing creates a thicker, more wear-resistant surface layer that often appears matte and slightly rougher, providing superior durability for industrial applications. The visual distinction lies in the softer luster of standard anodizing versus the robust, utilitarian finish of hard anodizing.

Applications of Standard Anodizing

Standard aluminum anodizing is widely used in decorative and protective applications, providing corrosion resistance and enhancing surface hardness for architectural panels, consumer electronics, and automotive parts. This process produces a thin, porous oxide layer that can be dyed in various colors, making it ideal for aesthetic purposes. Your choice of standard anodizing supports both durability and visual appeal without the increased thickness or hardness characteristic of hard anodizing.

Applications of Hard Anodizing

Hard anodizing is widely used in aerospace, automotive, and military industries where enhanced surface durability, corrosion resistance, and wear protection are critical. Its applications include aircraft structural components, automotive engine parts, and firearm barrels, benefiting from a thicker, harder oxide layer compared to standard aluminum anodizing. This process significantly improves the lifespan and performance of parts exposed to extreme environmental and mechanical conditions.

Choosing the Right Anodizing Type for Your Project

Aluminum anodizing enhances corrosion resistance and surface durability, while hard anodizing provides a thicker, more wear-resistant coating ideal for heavy-duty applications. Hard anodizing typically achieves oxide layer thicknesses between 25 to 150 microns, compared to conventional anodizing's 5 to 25 microns, making it suitable for parts requiring higher abrasion resistance. Choosing the right anodizing type depends on your project's performance requirements, environmental exposure, and mechanical stress factors to ensure optimal protection and longevity.

aluminum anodizing vs hard anodizing Infographic

libmatt.com

libmatt.com