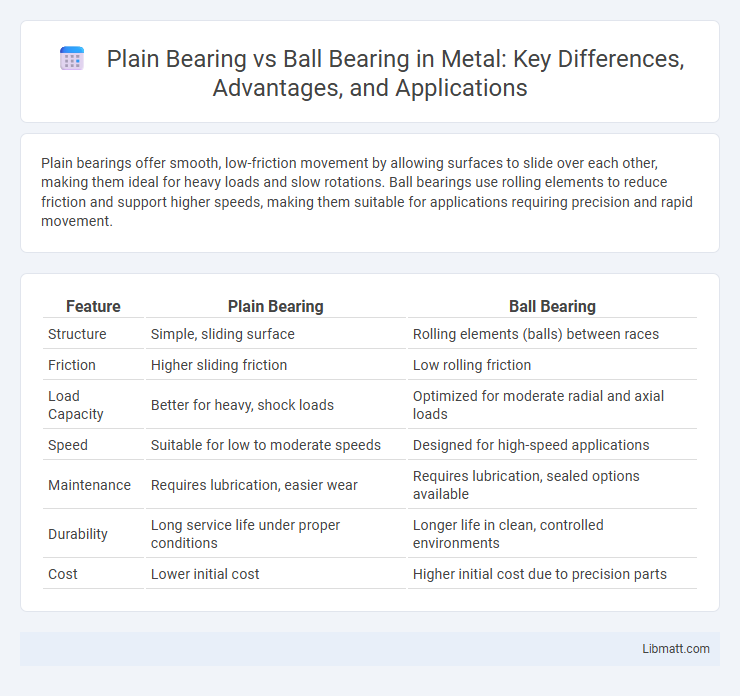

Plain bearings offer smooth, low-friction movement by allowing surfaces to slide over each other, making them ideal for heavy loads and slow rotations. Ball bearings use rolling elements to reduce friction and support higher speeds, making them suitable for applications requiring precision and rapid movement.

Table of Comparison

| Feature | Plain Bearing | Ball Bearing |

|---|---|---|

| Structure | Simple, sliding surface | Rolling elements (balls) between races |

| Friction | Higher sliding friction | Low rolling friction |

| Load Capacity | Better for heavy, shock loads | Optimized for moderate radial and axial loads |

| Speed | Suitable for low to moderate speeds | Designed for high-speed applications |

| Maintenance | Requires lubrication, easier wear | Requires lubrication, sealed options available |

| Durability | Long service life under proper conditions | Longer life in clean, controlled environments |

| Cost | Lower initial cost | Higher initial cost due to precision parts |

Introduction to Plain Bearings and Ball Bearings

Plain bearings provide smooth motion by using a sliding surface that reduces friction, ideal for applications with heavy loads and low-speed operations. Ball bearings utilize rolling elements to minimize friction and enhance rotational speed, making them suitable for high-speed machinery and precision equipment. Understanding the differences in load capacity, friction behavior, and maintenance needs can help you choose the right bearing type for your specific mechanical requirements.

Fundamental Differences: Design and Operation

Plain bearings feature a simple design with sliding contact surfaces that support loads through friction, using a lubricant film to reduce wear. Ball bearings utilize rolling elements--steel or ceramic balls--between inner and outer races to minimize friction by converting sliding motion into rolling motion. The fundamental operational difference lies in plain bearings relying on fluid or boundary lubrication for smooth movement, whereas ball bearings depend on rolling elements to achieve low-friction rotational motion with higher precision and speed capabilities.

Load Capacity: Plain vs Ball Bearings

Plain bearings typically offer higher load capacity than ball bearings due to their larger contact surface area, which distributes loads more evenly and reduces stress concentrations. Ball bearings excel in applications requiring lower friction and high-speed rotation but tend to have lower load capacity because their point contact supports less weight. Your choice between plain and ball bearings should depend on whether maximum load capacity or rotational speed and precision are the primary requirements.

Friction and Efficiency Comparison

Plain bearings typically exhibit higher friction coefficients ranging from 0.001 to 0.03 due to direct surface contact, resulting in lower efficiency compared to ball bearings. Ball bearings feature rolling elements that reduce friction significantly, with coefficients as low as 0.001, enhancing mechanical efficiency and energy savings. These friction characteristics influence selection criteria in applications where minimizing energy loss and maximizing operational longevity are critical.

Maintenance and Lifespan Considerations

Plain bearings require regular lubrication and are prone to wear due to metal-to-metal contact, impacting their maintenance frequency and lifespan. Ball bearings typically have sealed designs that reduce the need for frequent maintenance and provide longer service life under proper operating conditions. Choosing the right bearing depends on your application's load, speed, and maintenance capabilities to optimize durability and performance.

Cost Analysis: Initial and Long-Term Expenses

Plain bearings generally have lower initial costs due to simpler design and cheaper materials, making them economically favorable for applications with limited budgets. Ball bearings, while more expensive upfront because of precision manufacturing and complex components, often result in lower long-term expenses through enhanced durability, reduced friction, and extended maintenance intervals. The choice between the two depends on balancing immediate investment against lifecycle costs, considering factors like operating conditions and expected service life.

Application Suitability and Industry Usage

Plain bearings excel in heavy-load, low-speed applications such as construction machinery and agricultural equipment where durability and vibration dampening are critical. Ball bearings are preferred in high-speed, precision environments like automotive engines and aerospace systems due to their low friction and ability to handle radial and axial loads. Understanding your application's load, speed, and maintenance requirements will guide the choice between these bearing types to optimize performance and longevity.

Performance in Extreme Conditions

Plain bearings excel in extreme conditions due to their simple design and ability to operate with minimal lubrication, making them resistant to dust, dirt, and high temperatures. Ball bearings, while offering lower friction and higher precision, may struggle in harsh environments as their rolling elements and cages are more susceptible to contamination and thermal expansion. In applications involving heavy loads and abrasive conditions, plain bearings provide greater durability and reliability compared to ball bearings.

Noise and Vibration Characteristics

Plain bearings generate less noise and vibration compared to ball bearings due to their sliding motion and larger contact surface area, which dampens oscillations more effectively. Ball bearings, with their rolling elements, tend to produce higher noise levels and vibrations, especially at high speeds or under misalignment conditions. Understanding these characteristics helps you select the optimal bearing type for applications requiring quiet and smooth operation.

Choosing the Right Bearing for Your Needs

Selecting the right bearing hinges on load capacity, speed, and maintenance requirements, where plain bearings excel in handling heavy loads at low speeds with minimal noise and cost, while ball bearings offer superior performance at high speeds and precise movement with lower friction. Plain bearings are ideal for applications requiring simple design and durability under heavy, oscillating loads, whereas ball bearings suit high-speed machinery with rotational accuracy and reduced wear. Understanding operational conditions and environmental factors ensures optimal bearing choice for longevity and efficiency.

plain bearing vs ball bearing Infographic

libmatt.com

libmatt.com