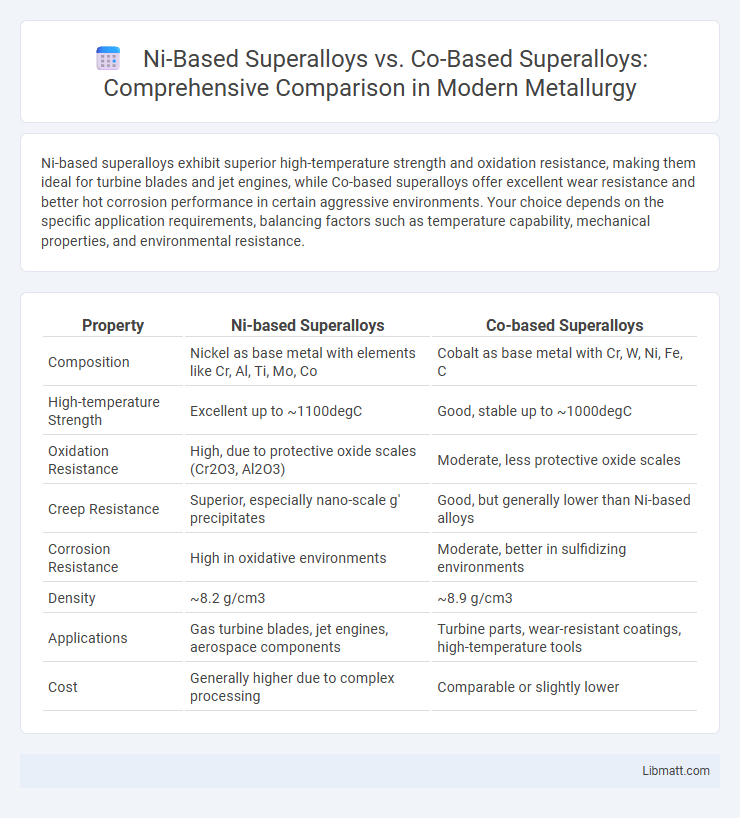

Ni-based superalloys exhibit superior high-temperature strength and oxidation resistance, making them ideal for turbine blades and jet engines, while Co-based superalloys offer excellent wear resistance and better hot corrosion performance in certain aggressive environments. Your choice depends on the specific application requirements, balancing factors such as temperature capability, mechanical properties, and environmental resistance.

Table of Comparison

| Property | Ni-based Superalloys | Co-based Superalloys |

|---|---|---|

| Composition | Nickel as base metal with elements like Cr, Al, Ti, Mo, Co | Cobalt as base metal with Cr, W, Ni, Fe, C |

| High-temperature Strength | Excellent up to ~1100degC | Good, stable up to ~1000degC |

| Oxidation Resistance | High, due to protective oxide scales (Cr2O3, Al2O3) | Moderate, less protective oxide scales |

| Creep Resistance | Superior, especially nano-scale g' precipitates | Good, but generally lower than Ni-based alloys |

| Corrosion Resistance | High in oxidative environments | Moderate, better in sulfidizing environments |

| Density | ~8.2 g/cm3 | ~8.9 g/cm3 |

| Applications | Gas turbine blades, jet engines, aerospace components | Turbine parts, wear-resistant coatings, high-temperature tools |

| Cost | Generally higher due to complex processing | Comparable or slightly lower |

Introduction to Ni-Based and Co-Based Superalloys

Ni-based superalloys exhibit superior high-temperature strength and oxidation resistance, making them the preferred choice for turbine blades and jet engines. Co-based superalloys offer enhanced hot corrosion resistance and higher thermal fatigue strength, ideal for extreme combustion environments. Your selection between Ni-based and Co-based superalloys depends on the specific application requirements such as operating temperature and environmental conditions.

Historical Development and Evolution

Ni-based superalloys emerged in the 1940s, driven by the aerospace industry's demand for materials with exceptional high-temperature strength and oxidation resistance. Co-based superalloys, developed slightly later, offered superior corrosion resistance and wear properties, often catering to different industrial applications such as cutting tools and gas turbines. Your choice between Ni-based and Co-based superalloys depends on balancing high-temperature performance with environmental resistance, reflecting their distinct evolutionary paths shaped by specific engineering challenges.

Chemical Composition and Alloying Elements

Ni-based superalloys primarily contain nickel as the base element, supplemented with chromium, cobalt, aluminum, titanium, and molybdenum to enhance high-temperature strength and corrosion resistance. Co-based superalloys feature cobalt as the matrix, with significant amounts of chromium, tungsten, and tantalum, promoting wear resistance and stability at elevated temperatures. Your choice between these alloys depends on the specific performance requirements, such as thermal stability or oxidation resistance, dictated by their distinct chemical compositions and alloying elements.

Microstructural Characteristics

Ni-based superalloys exhibit a complex microstructure characterized by a g matrix strengthened with coherent g' (Ni3Al) precipitates, enhancing their high-temperature strength and creep resistance. Co-based superalloys generally feature a g matrix with g' and carbides, providing superior corrosion and wear resistance but often less pronounced precipitation hardening compared to Ni-based alloys. Your choice between these superalloys depends on the required balance between microstructural stability and environmental resistance at elevated temperatures.

Mechanical Properties Comparison

Ni-based superalloys exhibit superior high-temperature strength and creep resistance due to their gamma-prime (g') phase precipitation, making them ideal for turbine blades and aerospace applications. Co-based superalloys offer enhanced wear resistance and corrosion resistance, especially in thermal oxidative environments, but generally have lower creep resistance at extreme temperatures. The mechanical properties of Ni-based superalloys typically outperform Co-based variants in tensile strength and fatigue life under prolonged high-temperature exposure.

High-Temperature Performance and Oxidation Resistance

Ni-based superalloys exhibit superior high-temperature performance due to their stable gamma-prime (g') precipitates, maintaining strength and creep resistance above 1000degC, while Co-based superalloys generally perform well up to 900-950degC with lower creep resistance. Oxidation resistance in Ni-based superalloys benefits from the formation of a protective alumina (Al2O3) scale, whereas Co-based superalloys rely on chromium oxide (Cr2O3) scales that offer comparatively less stability at extreme temperatures. These differences influence the selection of superalloys for gas turbine and aerospace applications where sustained high-temperature strength and oxidation resistance are critical.

Applications in Aerospace and Power Generation

Ni-based superalloys dominate aerospace and power generation sectors due to their exceptional high-temperature strength, oxidation resistance, and creep resistance, allowing turbine blades and jet engine components to maintain structural integrity under extreme conditions. Co-based superalloys, while less common, offer superior wear and corrosion resistance and are increasingly used in specialized aerospace components and high-performance gas turbine parts where thermal fatigue and corrosion are critical concerns. Your choice between these materials depends on balancing temperature capabilities with environmental resistance for optimal performance in demanding aerospace and power generation applications.

Manufacturing and Processing Techniques

Ni-based superalloys typically utilize advanced casting and powder metallurgy techniques, including investment casting and hot isostatic pressing, to achieve complex geometries and superior mechanical properties. Co-based superalloys often require hot working processes like forging and extrusion to enhance their inherent wear resistance and thermal stability. Your choice between Ni-based and Co-based superalloys impacts the manufacturing route due to differences in melting points, phase stability, and response to heat treatment.

Cost and Availability Considerations

Ni-based superalloys generally offer more cost-effective solutions due to their widespread availability and established supply chains compared to the rarer and often pricier Co-based superalloys. Your choice may depend on budget constraints, as Co-based superalloys tend to have higher raw material costs and more limited sources. These factors significantly impact procurement strategies and overall project feasibility in high-temperature applications.

Future Trends and Research Directions

Ni-based superalloys continue to dominate high-temperature applications due to their superior creep resistance and thermal stability, yet research increasingly explores Co-based superalloys for their exceptional wear resistance and corrosion behavior at elevated temperatures. Future trends emphasize developing novel alloy compositions with enhanced oxidation resistance and lightweight properties, leveraging advanced computational modeling and additive manufacturing techniques to optimize microstructures. Your investment in these materials can benefit from ongoing studies targeting improved performance in aerospace turbines and next-generation power plants.

Ni-based superalloys vs Co-based superalloys Infographic

libmatt.com

libmatt.com