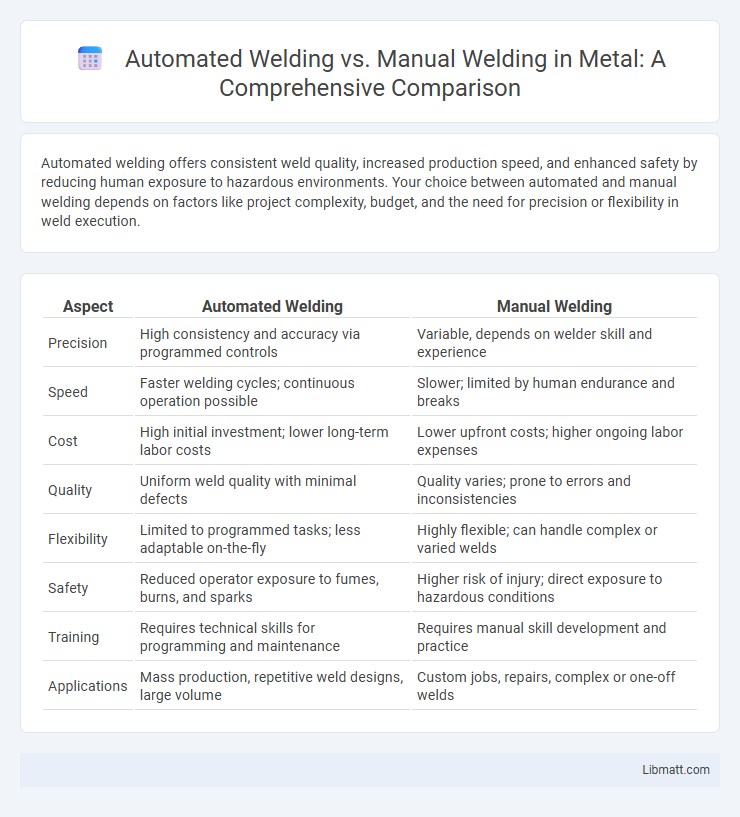

Automated welding offers consistent weld quality, increased production speed, and enhanced safety by reducing human exposure to hazardous environments. Your choice between automated and manual welding depends on factors like project complexity, budget, and the need for precision or flexibility in weld execution.

Table of Comparison

| Aspect | Automated Welding | Manual Welding |

|---|---|---|

| Precision | High consistency and accuracy via programmed controls | Variable, depends on welder skill and experience |

| Speed | Faster welding cycles; continuous operation possible | Slower; limited by human endurance and breaks |

| Cost | High initial investment; lower long-term labor costs | Lower upfront costs; higher ongoing labor expenses |

| Quality | Uniform weld quality with minimal defects | Quality varies; prone to errors and inconsistencies |

| Flexibility | Limited to programmed tasks; less adaptable on-the-fly | Highly flexible; can handle complex or varied welds |

| Safety | Reduced operator exposure to fumes, burns, and sparks | Higher risk of injury; direct exposure to hazardous conditions |

| Training | Requires technical skills for programming and maintenance | Requires manual skill development and practice |

| Applications | Mass production, repetitive weld designs, large volume | Custom jobs, repairs, complex or one-off welds |

Introduction to Welding Methods

Automated welding uses robotics and computer-controlled systems to deliver consistent, high-quality welds with increased speed and precision, reducing human error and labor costs. Manual welding relies on skilled welders to operate welding equipment directly, offering flexibility for complex or custom projects but is more prone to variability and slower production. Your choice between automated and manual welding depends on factors like project scale, complexity, budget, and the desired balance between efficiency and craftsmanship.

Overview of Automated Welding

Automated welding utilizes advanced machinery and robotic systems to perform precise and consistent welds, significantly increasing production speed and reducing human error. This technology is especially beneficial in industries requiring high-volume output and stringent quality control, such as automotive and aerospace manufacturing. Your manufacturing process can achieve enhanced efficiency and safety by integrating automated welding solutions compared to traditional manual welding methods.

Overview of Manual Welding

Manual welding relies on skilled welders who control the welding torch and filler material by hand, enabling precise adjustments based on visual inspection and experience. It offers greater flexibility for complex or customized projects where robotic programming may be impractical or cost-prohibitive. Despite higher labor costs and variability in weld quality, manual welding remains essential in industries requiring intricate joint configurations and on-site repairs.

Precision and Consistency Comparison

Automated welding offers superior precision and consistency compared to manual welding by utilizing programmed controls and robotic arms that maintain exact parameters throughout the process. This technology minimizes human error, resulting in uniform weld quality and reduced material waste. Your projects benefit from enhanced reliability and repeatability, critical for industries requiring high standards such as aerospace and automotive manufacturing.

Efficiency and Productivity Analysis

Automated welding significantly enhances efficiency by maintaining consistent weld quality and reducing the need for rework, making it ideal for high-volume production environments. Manual welding relies heavily on operator skill and speed, which can result in variability and slower throughput compared to automation. Your choice between these methods impacts productivity metrics, with automated systems delivering faster cycle times and increased output.

Cost Implications of Automated vs Manual Welding

Automated welding significantly reduces labor costs by minimizing the need for skilled welders and increasing production speed, resulting in higher throughput and lower per-unit expenses. Initial investment in robotic systems and maintenance can be substantial, but the long-term return on investment is often favorable due to consistent quality and reduced rework. Manual welding incurs lower upfront equipment costs but generally demands higher labor expenses and increased variability in weld quality, which can lead to costly repairs and downtime.

Safety Considerations in Welding Processes

Automated welding significantly enhances safety by minimizing human exposure to hazardous fumes, intense light, and high temperatures, reducing the risk of burns and respiratory issues. Manual welding poses greater safety challenges due to direct operator involvement with hot materials and potentially harmful UV radiation. Implementing robotic welding systems alongside effective ventilation and protective gear further mitigates workplace accidents and long-term health hazards.

Skill Requirements and Training Needs

Automated welding systems significantly reduce the skill requirements and training time compared to manual welding, as robotic setups are programmed to perform precise, repetitive tasks with minimal human intervention. Manual welding demands extensive hands-on experience and advanced skills in technique, heat control, and positioning to ensure quality welds, often requiring years of training and practice. Investing in automated welding training focuses more on programming, maintenance, and supervision, while manual welding training centers on developing craftsmanship and adaptability.

Applications and Industry Use Cases

Automated welding dominates high-volume industries like automotive, aerospace, and shipbuilding, where precision and repeatability are crucial for manufacturing complex components and assemblies. Manual welding remains essential in construction, repair, and custom fabrication sectors, offering flexibility and adaptability for intricate or non-standard tasks. Both methods serve aerospace quality standards and heavy machinery production, with automation enhancing efficiency and manual welding providing skilled craftsmanship for unique applications.

Future Trends in Welding Technologies

Automated welding technologies are rapidly advancing with innovations such as AI-powered robotic welders and real-time monitoring systems that enhance precision and efficiency. Manual welding remains essential for complex, customized tasks but is increasingly complemented by hybrid systems that combine human skill with automation. Your welding operations can benefit from integrating these future trends, boosting productivity and consistency while reducing labor costs and error rates.

automated welding vs manual welding Infographic

libmatt.com

libmatt.com