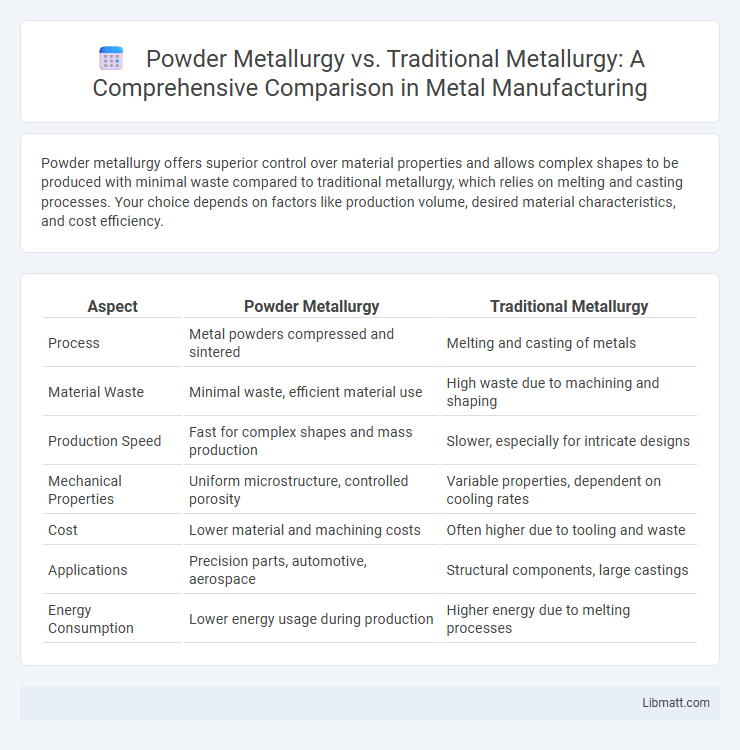

Powder metallurgy offers superior control over material properties and allows complex shapes to be produced with minimal waste compared to traditional metallurgy, which relies on melting and casting processes. Your choice depends on factors like production volume, desired material characteristics, and cost efficiency.

Table of Comparison

| Aspect | Powder Metallurgy | Traditional Metallurgy |

|---|---|---|

| Process | Metal powders compressed and sintered | Melting and casting of metals |

| Material Waste | Minimal waste, efficient material use | High waste due to machining and shaping |

| Production Speed | Fast for complex shapes and mass production | Slower, especially for intricate designs |

| Mechanical Properties | Uniform microstructure, controlled porosity | Variable properties, dependent on cooling rates |

| Cost | Lower material and machining costs | Often higher due to tooling and waste |

| Applications | Precision parts, automotive, aerospace | Structural components, large castings |

| Energy Consumption | Lower energy usage during production | Higher energy due to melting processes |

Introduction to Powder Metallurgy and Traditional Metallurgy

Powder metallurgy involves producing metal parts by compacting fine metal powders and sintering them at high temperatures, offering precise control over material properties and minimal waste. Traditional metallurgy relies on melting and casting metals, shaping components through forging, rolling, and machining processes that often result in higher material loss. Understanding the benefits of powder metallurgy can enhance your manufacturing efficiency with improved material utilization and complex geometries.

Basic Principles and Processes

Powder metallurgy involves producing metal parts by compacting fine metal powders and sintering them at high temperatures, enabling precise control over composition and microstructure. Traditional metallurgy relies on melting and casting metals, followed by deformation processes like forging and rolling to shape the material. Powder metallurgy offers advantages such as reduced material waste and the ability to create complex geometries that are challenging for conventional metallurgical methods.

Materials Used in Each Technique

Powder metallurgy primarily utilizes fine metal powders such as iron, copper, aluminum, and their alloys, enabling precise control over material composition and microstructure. Traditional metallurgy typically processes bulk metals and ores, including steel, cast iron, and various alloys, relying on melting and casting methods that can limit material uniformity. Your choice between these techniques depends on the specific material properties and production requirements desired for the application.

Key Differences in Manufacturing Methods

Powder metallurgy involves compacting metal powders into desired shapes followed by sintering, whereas traditional metallurgy primarily relies on melting and casting metals. Powder metallurgy offers precise control over material composition and minimal waste, while traditional methods often require extensive machining and involve higher energy consumption. The powder process allows manufacturing complex geometries and materials that are difficult to achieve through conventional casting or forging techniques.

Mechanical Properties Comparison

Powder metallurgy often yields superior mechanical properties such as higher strength, improved wear resistance, and better hardness compared to traditional metallurgy due to its fine and uniform microstructure. The controlled particle size and sintering processes in powder metallurgy enhance mechanical performance by reducing porosity and increasing density. Your choice between these methods should consider that powder metallurgy allows for tailored properties and complex shapes with minimal material waste, unlike conventional casting or forging.

Cost Efficiency and Economic Considerations

Powder metallurgy offers superior cost efficiency compared to traditional metallurgy by minimizing material waste and reducing machining time through near-net shape manufacturing. The use of powdered materials enables lower energy consumption during production, leading to significant savings in operational expenses. Economically, powder metallurgy supports large-scale, high-volume production with consistent quality, decreasing overall product costs and enhancing profitability.

Environmental Impact and Sustainability

Powder metallurgy significantly reduces material waste by utilizing precise powder consolidation techniques, enhancing sustainability compared to traditional metallurgy, which often involves extensive machining and higher scrap rates. The lower energy consumption in powder metallurgy processes, due to near-net shape manufacturing, results in decreased greenhouse gas emissions and a smaller carbon footprint. Traditional metallurgy typically relies on high-temperature smelting and refining, generating more pollutants and environmental degradation than the eco-friendly powder metallurgy approach.

Application Areas and Industry Usage

Powder metallurgy excels in producing complex, high-precision components used in automotive, aerospace, and medical industries due to its ability to create parts with controlled porosity and superior material utilization. Traditional metallurgy remains dominant in heavy industries such as construction, shipbuilding, and large-scale manufacturing where large, solid metal components and structural strength are prioritized. Both techniques cater to distinct industry requirements, with powder metallurgy favoring lightweight, wear-resistant parts and traditional metallurgy supporting large-scale, high-strength applications.

Advantages and Limitations of Each Method

Powder metallurgy offers advantages such as superior material utilization, complex shape formation, and consistent microstructure control, making it ideal for high-precision and lightweight components while reducing waste. Traditional metallurgy allows for the production of large, strong parts with established manufacturing processes but often involves higher energy consumption and limited shape complexity. Your choice between these methods depends on factors like production volume, design intricacy, material properties, and cost efficiency.

Future Trends in Metallurgical Technologies

Powder metallurgy is driving future trends in metallurgical technologies by enabling precise alloy compositions and reducing material waste compared to traditional metallurgy methods. Innovations like additive manufacturing and advanced sintering techniques enhance the production of complex, high-performance metal parts with improved mechanical properties and sustainability. Integration of digital control systems and AI in powder metallurgy processes promises increased efficiency, customizability, and reduced energy consumption in metal fabrication.

Powder metallurgy vs traditional metallurgy Infographic

libmatt.com

libmatt.com