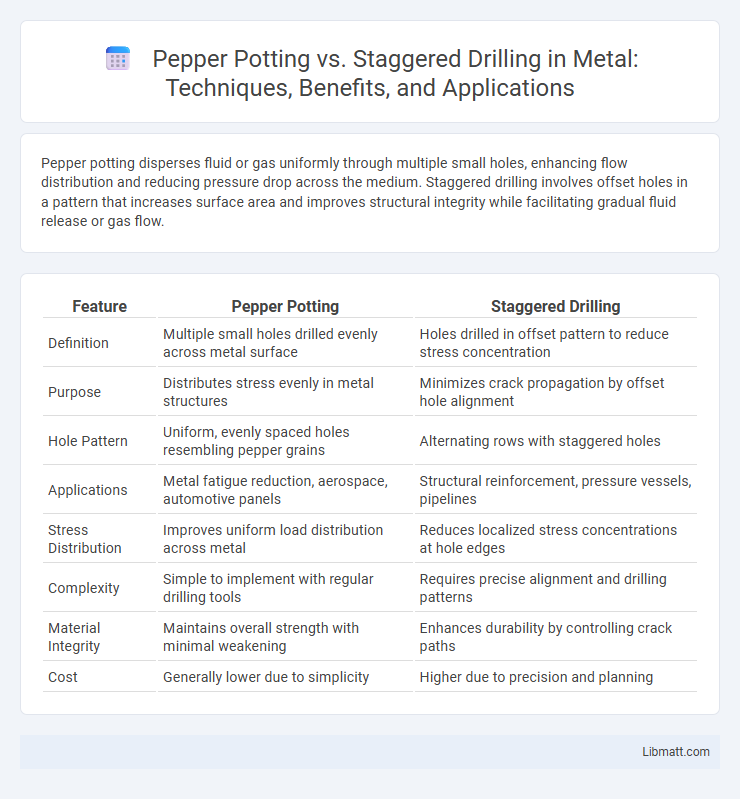

Pepper potting disperses fluid or gas uniformly through multiple small holes, enhancing flow distribution and reducing pressure drop across the medium. Staggered drilling involves offset holes in a pattern that increases surface area and improves structural integrity while facilitating gradual fluid release or gas flow.

Table of Comparison

| Feature | Pepper Potting | Staggered Drilling |

|---|---|---|

| Definition | Multiple small holes drilled evenly across metal surface | Holes drilled in offset pattern to reduce stress concentration |

| Purpose | Distributes stress evenly in metal structures | Minimizes crack propagation by offset hole alignment |

| Hole Pattern | Uniform, evenly spaced holes resembling pepper grains | Alternating rows with staggered holes |

| Applications | Metal fatigue reduction, aerospace, automotive panels | Structural reinforcement, pressure vessels, pipelines |

| Stress Distribution | Improves uniform load distribution across metal | Reduces localized stress concentrations at hole edges |

| Complexity | Simple to implement with regular drilling tools | Requires precise alignment and drilling patterns |

| Material Integrity | Maintains overall strength with minimal weakening | Enhances durability by controlling crack paths |

| Cost | Generally lower due to simplicity | Higher due to precision and planning |

Introduction to Drilling Techniques

Pepper potting and staggered drilling are advanced drilling techniques designed for precise material removal and enhanced structural integrity. Pepper potting involves creating a pattern of closely spaced small holes to reduce material stress and improve flexibility, often used in composite materials. Staggered drilling arranges holes in an offset pattern to distribute loads evenly and minimize crack propagation, ensuring durability and performance of drilled components.

What is Pepper Potting?

Pepper potting is a drilling technique used to enhance gas extraction or fluid flow by creating multiple small-diameter holes in a staggered pattern, increasing the surface area exposed to the reservoir. This method contrasts with staggered drilling, which typically involves fewer, larger holes arranged in a non-uniform pattern. You can optimize recovery and drainage efficiency by choosing pepper potting for complex reservoirs requiring extensive contact points.

What is Staggered Drilling?

Staggered drilling is a technique used in machining where holes are drilled in alternating or offset patterns to reduce stress and improve material stability. This method enhances heat dissipation and chip removal compared to pepper potting, which involves drilling multiple holes in a grid-like arrangement. Your choice of staggered drilling can increase tool life and improve overall machining efficiency in complex metalworking tasks.

Key Differences Between Pepper Potting and Staggered Drilling

Pepper potting uses closely spaced, small-diameter holes to enhance fluid flow and reduce weight, while staggered drilling involves offsetting larger holes in a zigzag pattern to maintain structural integrity. Pepper potting is ideal for lightweight composites requiring uniform stress distribution, whereas staggered drilling suits applications needing balanced mechanical strength and reduced stress concentration. The key difference lies in hole size, spacing, and the resulting impact on material performance and stress management.

Advantages of Pepper Potting

Pepper potting offers enhanced ventilation and improved fluid drainage by creating multiple small perforations, which prevents material weakening compared to staggered drilling's larger holes. This method increases the surface area for airflow and liquid passage, making it ideal for applications requiring efficient pressure equalization. You benefit from reduced structural stress and better moisture control with pepper potting's finely distributed perforations.

Advantages of Staggered Drilling

Staggered drilling enhances wellbore stability by minimizing formation damage and optimizing fluid distribution within the reservoir. This technique improves production efficiency by creating multiple drainage pathways, reducing pressure drop, and increasing hydrocarbon recovery. Moreover, staggered drilling allows for better control over trajectory accuracy and reduces the risk of wellbore collision in complex geological settings.

Common Applications for Each Technique

Pepper potting is commonly used in aerospace and automotive industries for creating lightweight, high-strength composite materials by evenly distributing resin through layers. Staggered drilling is often applied in structural engineering and metal fabrication to reduce stress concentration and prevent crack propagation in load-bearing components. Your choice between these techniques should consider the material type and desired mechanical properties for optimal performance.

Factors Influencing Technique Selection

Factors influencing the selection between pepper potting and staggered drilling primarily include the material type, desired ventilation or fluid flow rate, and structural integrity requirements. Pepper potting is favored for materials requiring uniform distribution of small perforations, optimizing permeability and minimizing stress concentration. Staggered drilling suits applications needing larger, spaced holes that enhance mechanical strength and ease of manufacturing while maintaining fluid flow efficiency.

Challenges and Limitations

Pepper potting faces challenges such as uneven material distribution and potential weakening of structural integrity due to closely spaced perforations. Staggered drilling, while improving hole distribution and stress management, may encounter limitations in precision and increased complexity in drill path planning. Your choice between these methods should consider material properties and the specific application to minimize defects and optimize performance.

Conclusion: Choosing the Right Drilling Method

Selecting the appropriate drilling method depends on project goals, subsurface conditions, and operational efficiency. Pepper potting offers precision in unstable formations by distributing perforations evenly, reducing stress concentration and improving wellbore stability. Staggered drilling enhances reservoir contact and fluid flow by alternating shot patterns, making it ideal for maximizing production in heterogeneous formations.

Pepper Potting vs Staggered Drilling Infographic

libmatt.com

libmatt.com