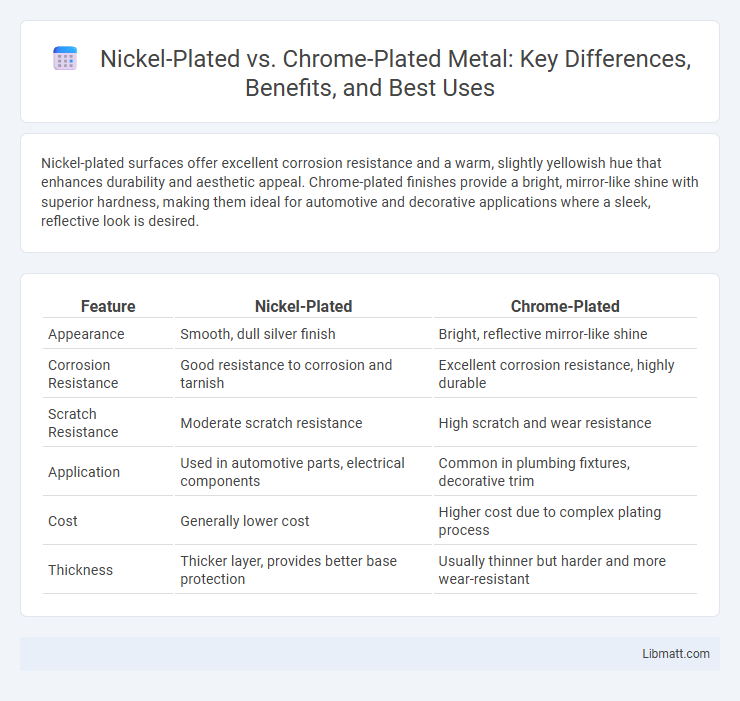

Nickel-plated surfaces offer excellent corrosion resistance and a warm, slightly yellowish hue that enhances durability and aesthetic appeal. Chrome-plated finishes provide a bright, mirror-like shine with superior hardness, making them ideal for automotive and decorative applications where a sleek, reflective look is desired.

Table of Comparison

| Feature | Nickel-Plated | Chrome-Plated |

|---|---|---|

| Appearance | Smooth, dull silver finish | Bright, reflective mirror-like shine |

| Corrosion Resistance | Good resistance to corrosion and tarnish | Excellent corrosion resistance, highly durable |

| Scratch Resistance | Moderate scratch resistance | High scratch and wear resistance |

| Application | Used in automotive parts, electrical components | Common in plumbing fixtures, decorative trim |

| Cost | Generally lower cost | Higher cost due to complex plating process |

| Thickness | Thicker layer, provides better base protection | Usually thinner but harder and more wear-resistant |

Introduction to Metal Plating Techniques

Nickel-plated surfaces provide excellent corrosion resistance and a smooth, durable finish ideal for both industrial and decorative applications. Chrome plating offers a highly reflective, mirror-like appearance with superior hardness, making it popular for automotive and household fixtures. Understanding these metal plating techniques helps you choose the right finish based on factors like durability, aesthetics, and environmental exposure.

What is Nickel Plating?

Nickel plating involves applying a thin layer of nickel onto a metal surface through electroplating, enhancing corrosion resistance and providing a smooth, durable finish. This process offers excellent adhesion qualities and improved wear resistance, making it ideal for protecting automotive parts, electronic components, and household fixtures. Nickel plating also imparts a bright, silvery appearance that resists tarnishing better than many other metals.

What is Chrome Plating?

Chrome plating is a metal finishing process where a thin layer of chromium is electroplated onto a metal or plastic object to enhance corrosion resistance, surface hardness, and aesthetic appeal. This coating provides a distinctive bright, mirror-like finish that is highly resistant to tarnishing and scratching. Commonly used in automotive parts, plumbing fixtures, and hardware, chrome plating improves durability while delivering a sleek, reflective surface.

Key Differences Between Nickel and Chrome Plating

Nickel plating offers excellent corrosion resistance and a warm, reflective finish, while chrome plating provides a harder, more durable surface with a bright, mirror-like shine. Nickel coatings are often used for decorative and protective purposes on automotive parts and hardware, whereas chrome plating is preferred for its scratch resistance and ease of cleaning in applications like plumbing fixtures and tools. Your choice depends on the desired aesthetic, durability, and environmental exposure for the plated item.

Appearance and Finish Comparison

Nickel-plated surfaces exhibit a warm, slightly yellowish metallic hue with a smooth, satin-like finish that offers moderate reflectivity, enhancing durability and corrosion resistance. Chrome-plated finishes provide a bright, mirror-like, highly reflective surface with a cooler silver tone, known for its exceptional hardness and superior resistance to tarnishing and scratching. Both plating types enhance aesthetic appeal but nickel plating is preferred for vintage or industrial looks, while chrome plating is favored for modern, sleek designs.

Durability and Corrosion Resistance

Nickel-plated surfaces offer superior corrosion resistance due to their dense, compact structure, making them highly durable in harsh environments and ideal for protecting underlying metals from rust and wear. Chrome-plated finishes provide excellent hardness and surface gloss, enhancing scratch resistance but are generally less effective against corrosion compared to nickel plating, especially in moist or acidic conditions. Choosing between nickel-plated and chrome-plated coatings depends on the specific application's exposure to corrosive elements and required longevity.

Maintenance Requirements

Nickel-plated surfaces demand regular cleaning with mild soap and water to prevent tarnishing and corrosion, while avoiding abrasive materials that can scratch the finish. Chrome-plated items require less frequent maintenance, benefiting from simple wiping with a soft cloth and occasional polishing to preserve their bright, reflective appearance. Your choice between the two will impact the ease of upkeep, with chrome plating generally offering more durable resistance to environmental wear.

Cost Analysis: Nickel vs Chrome Plating

Nickel plating generally costs less than chrome plating due to lower material and processing expenses, making it a budget-friendly option for corrosion resistance and aesthetic appeal. Chrome plating, while more expensive, offers superior hardness and a highly reflective finish, justifying the higher price for automotive and decorative applications. Cost analysis reveals that nickel plating balances affordability and durability, whereas chrome plating demands a premium for enhanced performance and visual impact.

Common Applications of Each Plating Type

Nickel-plated finishes are commonly used in automotive parts, household appliances, and electronic components due to their excellent corrosion resistance and decorative shine. Chrome-plated surfaces are favored for automotive trim, motorcycle parts, and plumbing fixtures because of their superior hardness and mirror-like luster. You can choose nickel plating for enhanced durability in industrial settings, while chrome plating is ideal for maintaining a sleek, reflective appearance on consumer products.

Choosing the Right Plating for Your Needs

Nickel-plated surfaces provide superior corrosion resistance and excellent adhesion, making them ideal for tools and automotive parts exposed to harsh environments. Chrome plating offers a highly reflective, mirror-like finish with enhanced hardness, perfect for decorative applications and wear resistance. You should choose nickel plating for durability and corrosion protection, while chrome plating suits aesthetic appeal and surface hardness requirements.

Nickel-Plated vs Chrome-Plated Infographic

libmatt.com

libmatt.com