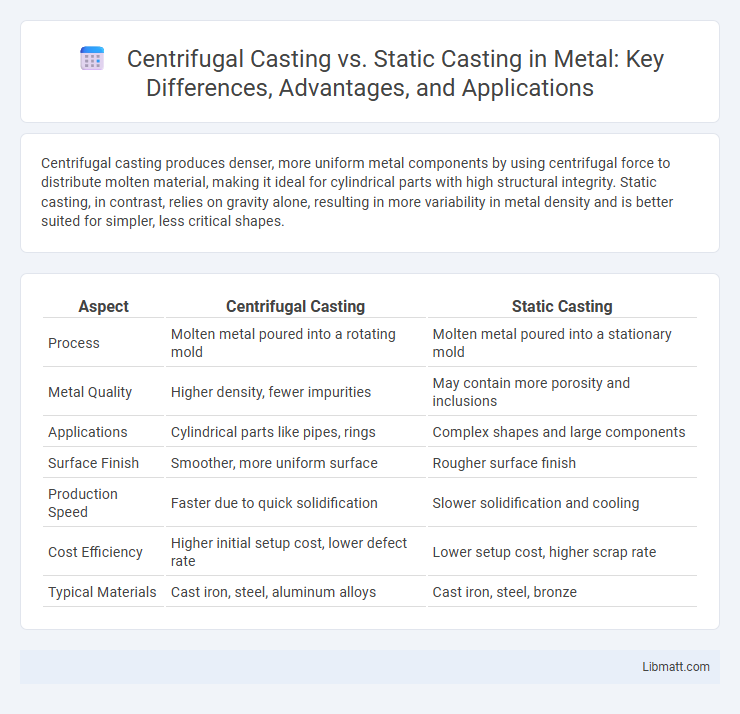

Centrifugal casting produces denser, more uniform metal components by using centrifugal force to distribute molten material, making it ideal for cylindrical parts with high structural integrity. Static casting, in contrast, relies on gravity alone, resulting in more variability in metal density and is better suited for simpler, less critical shapes.

Table of Comparison

| Aspect | Centrifugal Casting | Static Casting |

|---|---|---|

| Process | Molten metal poured into a rotating mold | Molten metal poured into a stationary mold |

| Metal Quality | Higher density, fewer impurities | May contain more porosity and inclusions |

| Applications | Cylindrical parts like pipes, rings | Complex shapes and large components |

| Surface Finish | Smoother, more uniform surface | Rougher surface finish |

| Production Speed | Faster due to quick solidification | Slower solidification and cooling |

| Cost Efficiency | Higher initial setup cost, lower defect rate | Lower setup cost, higher scrap rate |

| Typical Materials | Cast iron, steel, aluminum alloys | Cast iron, steel, bronze |

Overview of Centrifugal Casting

Centrifugal casting utilizes a rapidly spinning mold to force molten metal against its inner walls, creating dense, high-integrity cylindrical or tubular components. This process enhances material properties by reducing impurities and porosity due to centrifugal force, which drives heavier elements outward and separates slag or gas inclusions. Compared to static casting, centrifugal casting offers superior mechanical strength, uniformity, and improved grain structure in parts such as pipes, rings, and bushings.

Overview of Static Casting

Static casting involves pouring molten metal into a stationary mold, allowing the material to cool and solidify under gravity without external forces. This method produces uniform, dense castings ideal for simple shapes and moderate production volumes, offering greater dimensional accuracy compared to centrifugal casting. Your selection of static casting ensures cost-effective manufacturing for components requiring consistent mechanical properties and minimal structural defects.

Key Differences Between Centrifugal and Static Casting

Centrifugal casting uses a rapidly spinning mold to distribute molten metal by centrifugal force, resulting in denser, stronger metal with fewer impurities, while static casting relies on gravity alone to fill the mold, often leading to more porosity and lower structural integrity. Key differences include the enhanced mechanical properties and superior surface finish achieved through centrifugal casting, compared to the simpler and more cost-effective static casting method. Your choice between these methods depends on the required material quality, complexity, and production volume.

Material Suitability for Each Casting Process

Centrifugal casting is highly suitable for producing cylindrical parts with metals like cast iron, steel, and copper alloys, thanks to its ability to create dense, fine-grained structures by using centrifugal force. Static casting works well with a variety of materials, including aluminum, brass, and bronze, but may result in uneven grain structures and porosity in larger or more complex shapes. Your choice of material should align with the casting process to optimize mechanical properties and reduce defects in the final product.

Process Steps: Centrifugal vs Static Casting

Centrifugal casting involves pouring molten metal into a rotating mold, which uses centrifugal force to distribute the metal evenly and eliminate impurities, enhancing density and mechanical properties. Static casting requires pouring molten metal into a stationary mold where gravity allows the metal to solidify naturally, often resulting in more porosity and less uniformity. Understanding these process steps can help you choose the optimal casting method based on your desired component quality and structural integrity.

Advantages of Centrifugal Casting

Centrifugal casting offers superior material density and enhanced mechanical properties compared to static casting due to the centrifugal force that distributes molten metal evenly, reducing porosity and impurities. This technique provides better dimensional accuracy and surface finish, minimizing machining requirements for your final product. Its ability to produce cylindrical components with consistent quality makes it ideal for pipes, rings, and automotive parts requiring high strength and reliability.

Advantages of Static Casting

Static casting offers advantages such as uniform thickness and consistent mechanical properties due to the absence of mold rotation. Your components benefit from reduced internal stresses and minimal defect formation, resulting in higher structural integrity. This method is cost-effective for producing complex shapes with fine surface finishes and fewer impurities.

Common Applications and Industries

Centrifugal casting is predominantly used in manufacturing pipes, cylinders, and rings for industries such as aerospace, automotive, and energy due to its superior density and mechanical properties. Static casting finds broad application in producing complex, large, and intricate parts like engine blocks and molds, commonly serving construction, heavy machinery, and tool manufacturing sectors. Both techniques optimize material utilization and structural integrity but cater to different industrial needs based on component shape and performance requirements.

Quality and Defect Comparison

Centrifugal casting typically produces higher quality components with fewer defects due to its ability to distribute molten metal evenly under centrifugal force, minimizing porosity and inclusions. Static casting often results in more common defects like shrinkage porosity and slag entrapment because the metal solidifies in a stationary mold where gravity can cause uneven cooling and segregation. The enhanced grain structure and density achieved in centrifugal casting improve mechanical properties and reduce internal flaws compared to static casting techniques.

Cost Considerations and Efficiency Analysis

Centrifugal casting typically incurs higher initial equipment costs due to specialized machinery but offers superior material utilization and reduced defects, enhancing long-term cost efficiency. Static casting involves lower upfront expenses and simpler setups but often results in increased scrap rates and longer cooling times, which can escalate production costs over time. Efficiency analysis shows centrifugal casting excels in producing high-quality cylindrical parts with consistent properties, while static casting suits lower-volume, less complex shapes with more variable quality control.

Centrifugal casting vs static casting Infographic

libmatt.com

libmatt.com