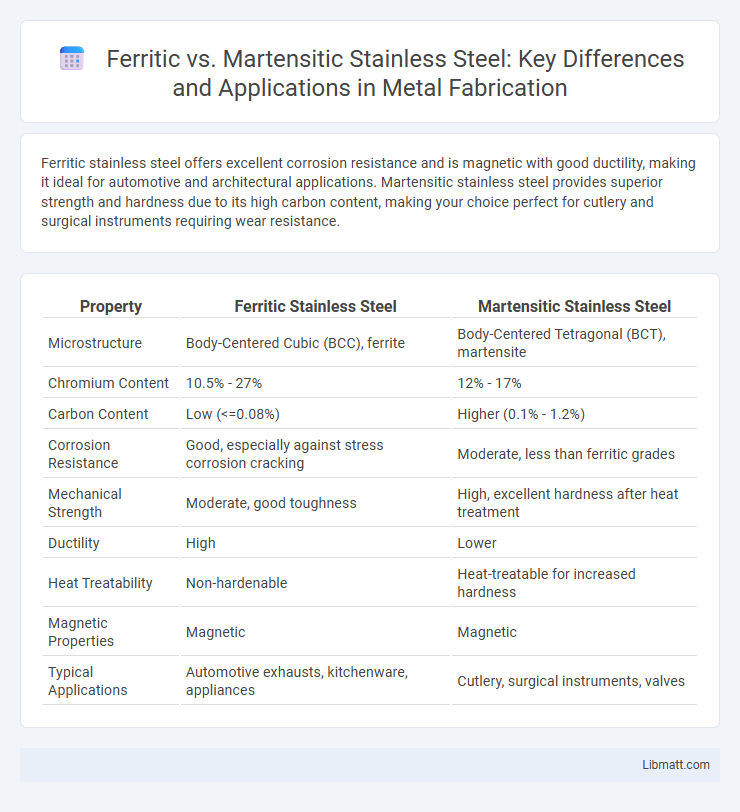

Ferritic stainless steel offers excellent corrosion resistance and is magnetic with good ductility, making it ideal for automotive and architectural applications. Martensitic stainless steel provides superior strength and hardness due to its high carbon content, making your choice perfect for cutlery and surgical instruments requiring wear resistance.

Table of Comparison

| Property | Ferritic Stainless Steel | Martensitic Stainless Steel |

|---|---|---|

| Microstructure | Body-Centered Cubic (BCC), ferrite | Body-Centered Tetragonal (BCT), martensite |

| Chromium Content | 10.5% - 27% | 12% - 17% |

| Carbon Content | Low (<=0.08%) | Higher (0.1% - 1.2%) |

| Corrosion Resistance | Good, especially against stress corrosion cracking | Moderate, less than ferritic grades |

| Mechanical Strength | Moderate, good toughness | High, excellent hardness after heat treatment |

| Ductility | High | Lower |

| Heat Treatability | Non-hardenable | Heat-treatable for increased hardness |

| Magnetic Properties | Magnetic | Magnetic |

| Typical Applications | Automotive exhausts, kitchenware, appliances | Cutlery, surgical instruments, valves |

Introduction to Ferritic and Martensitic Stainless Steels

Ferritic stainless steels contain high chromium content with low carbon, offering excellent corrosion resistance and magnetic properties ideal for automotive and kitchen applications. Martensitic stainless steels feature higher carbon content enabling heat treatment for superior hardness and strength, making them suitable for cutlery, tools, and turbine blades. Understanding these differences helps you select the right steel type based on mechanical performance and corrosion resistance requirements.

Chemical Composition Differences

Ferritic stainless steel primarily contains 10-30% chromium with very low carbon content, typically less than 0.1%, which gives it good corrosion resistance and magnetic properties. Martensitic stainless steel has higher carbon content, usually between 0.1-1.2%, combined with 12-18% chromium, enhancing hardness and strength but reducing corrosion resistance. The key difference lies in carbon levels and chromium percentage, directly impacting their mechanical properties and applications.

Microstructure Comparison

Ferritic stainless steel features a body-centered cubic (BCC) microstructure, characterized by its stable, magnetic, and relatively ductile nature. Martensitic stainless steel exhibits a body-centered tetragonal (BCT) structure, formed by rapid quenching that results in a harder, more brittle phase with enhanced strength. Your choice between these alloys depends on whether you prioritize corrosion resistance and ductility or high hardness and wear resistance.

Mechanical Properties Overview

Ferritic stainless steel exhibits moderate strength and high ductility, making it resistant to stress corrosion cracking but generally less hardenable through heat treatment. Martensitic stainless steel offers superior hardness, high tensile strength, and excellent wear resistance due to its ability to be heat-treated and tempered. While ferritic stainless steels are magnetic and maintain toughness at lower temperatures, martensitic variants deliver enhanced mechanical performance suitable for applications requiring cutting-edge strength and hardness.

Corrosion Resistance Capabilities

Ferritic stainless steel offers moderate corrosion resistance, particularly effective against stress corrosion cracking in chloride environments but less resistant to pitting and crevice corrosion compared to martensitic grades. Martensitic stainless steel provides higher hardness and strength but typically exhibits lower corrosion resistance, making it more prone to rust in aggressive environments unless properly alloyed or coated. Your choice depends on balancing corrosion resistance needs with mechanical strength requirements for optimal performance.

Common Applications

Ferritic stainless steel is commonly used in automotive trim, kitchen utensils, and industrial equipment due to its excellent corrosion resistance and good formability. Martensitic stainless steel finds widespread application in cutlery, surgical instruments, and turbine blades because of its high hardness and strength after heat treatment. Both types serve distinct industrial needs, with ferritic preferred for aesthetic and corrosion-resistant purposes while martensitic excels in wear-resistant and structural applications.

Heat Treatment and Hardening

Ferritic stainless steel exhibits limited hardening through heat treatment due to its body-centered cubic (BCC) structure, which prevents martensitic transformation. Martensitic stainless steel undergoes significant hardening when quenched from high temperatures, transforming its face-centered cubic (FCC) austenite phase into a brittle, hard martensite phase. Tempering martensitic stainless steel improves toughness while retaining hardness, making it ideal for applications requiring a balance of strength and wear resistance.

Machinability and Fabrication

Ferritic stainless steel offers superior machinability due to its lower carbon content and softer microstructure, allowing easier cutting, drilling, and shaping during fabrication. Martensitic stainless steel, known for its higher hardness and strength, presents challenges in machining processes, often requiring specialized tools and slower cutting speeds to prevent wear and heat buildup. Your choice between these steels should consider the balance between fabrication ease and desired mechanical properties for the final application.

Cost and Availability

Ferritic stainless steel generally offers lower cost and higher availability due to its simpler alloy composition and widespread use in automotive and construction industries. Martensitic stainless steel tends to be more expensive because of higher carbon content and heat treatment requirements, which enhance hardness and strength for applications like cutlery and aerospace. Your choice between ferritic and martensitic stainless steel should consider these factors alongside performance needs to balance budget and material availability.

Choosing the Right Stainless Steel Grade

Selecting between ferritic and martensitic stainless steel depends on application requirements such as corrosion resistance, mechanical strength, and heat treatment capabilities. Ferritic stainless steels offer excellent corrosion resistance and formability, making them ideal for automotive exhaust systems and architectural projects. Martensitic stainless steels provide higher hardness and tensile strength after heat treatment, suitable for cutlery, surgical instruments, and aerospace components.

Ferritic vs martensitic stainless steel Infographic

libmatt.com

libmatt.com