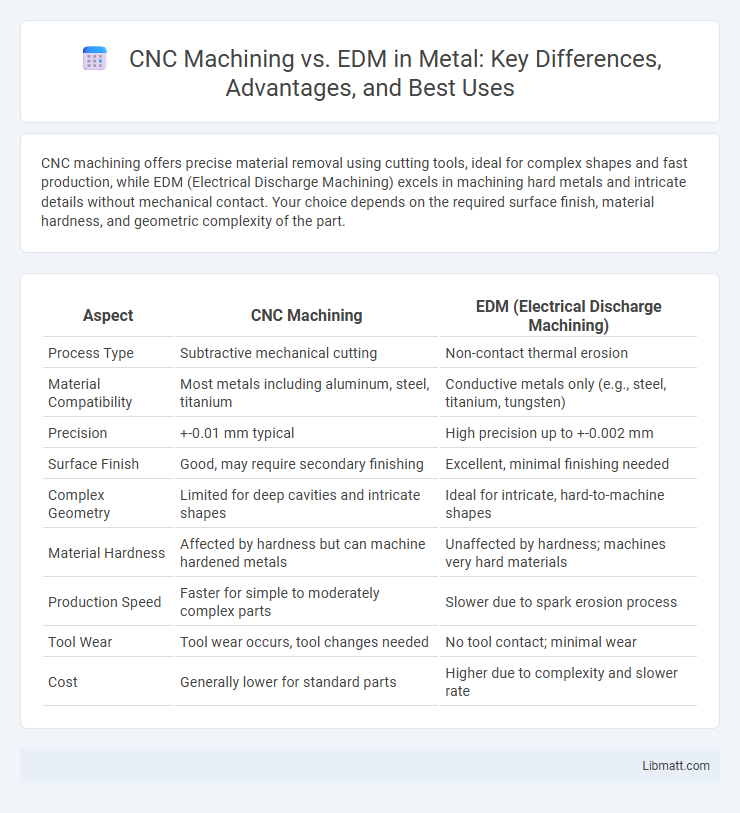

CNC machining offers precise material removal using cutting tools, ideal for complex shapes and fast production, while EDM (Electrical Discharge Machining) excels in machining hard metals and intricate details without mechanical contact. Your choice depends on the required surface finish, material hardness, and geometric complexity of the part.

Table of Comparison

| Aspect | CNC Machining | EDM (Electrical Discharge Machining) |

|---|---|---|

| Process Type | Subtractive mechanical cutting | Non-contact thermal erosion |

| Material Compatibility | Most metals including aluminum, steel, titanium | Conductive metals only (e.g., steel, titanium, tungsten) |

| Precision | +-0.01 mm typical | High precision up to +-0.002 mm |

| Surface Finish | Good, may require secondary finishing | Excellent, minimal finishing needed |

| Complex Geometry | Limited for deep cavities and intricate shapes | Ideal for intricate, hard-to-machine shapes |

| Material Hardness | Affected by hardness but can machine hardened metals | Unaffected by hardness; machines very hard materials |

| Production Speed | Faster for simple to moderately complex parts | Slower due to spark erosion process |

| Tool Wear | Tool wear occurs, tool changes needed | No tool contact; minimal wear |

| Cost | Generally lower for standard parts | Higher due to complexity and slower rate |

Introduction to CNC Machining and EDM

CNC machining utilizes computer-controlled cutting tools to shape metal and other materials with high precision and repeatability, making it ideal for medium to large production runs and complex geometries. EDM (Electrical Discharge Machining) removes material by using controlled electrical sparks, excelling in producing intricate designs and hard-to-machine materials with tight tolerances. Your choice between CNC machining and EDM depends on the complexity of the part, material properties, and desired surface finish.

How CNC Machining Works

CNC machining operates through computer numerical control systems that precisely guide cutting tools to remove material from a workpiece, achieving high accuracy and repeatability. It utilizes various cutting tools such as drills, mills, and lathes, controlled by G-code instructions to perform complex shapes and detailed finishes. This subtractive manufacturing process is ideal for metals and plastics, producing parts with tight tolerances and smooth surface finishes efficiently.

Understanding EDM (Electrical Discharge Machining)

Electrical Discharge Machining (EDM) uses controlled electrical discharges to erode material from a workpiece, allowing for precise machining of complex shapes and hard metals that are difficult to process with CNC machining. EDM operates without direct contact, minimizing mechanical stress and tool wear while achieving tight tolerances and smooth surface finishes. Your choice between CNC machining and EDM depends on material type, geometry complexity, and precision requirements.

Key Differences Between CNC Machining and EDM

CNC machining uses rotary cutting tools to remove material from a workpiece, excelling in producing complex shapes with tight tolerances and smooth finishes from metals, plastics, and composites. EDM (Electrical Discharge Machining) removes material through electrical sparks, ideal for hard metals and intricate geometries that are difficult to machine conventionally, such as deep cavities or thin walls. CNC machining operates via mechanical cutting and is faster for larger volumes, while EDM is slower but offers exceptional precision for delicate or heat-sensitive materials.

Material Compatibility: CNC vs EDM

CNC machining excels in processing a wide range of materials, including aluminum, steel, plastics, and softer metals, making it ideal for versatile manufacturing needs. EDM (Electrical Discharge Machining) specializes in hard, conductive materials such as hardened steel, titanium, and carbides that are difficult to machine with traditional methods. Your choice between CNC and EDM hinges on material compatibility, where EDM is preferred for intricate shapes in tough metals, while CNC offers faster production for softer materials.

Precision and Tolerance Comparison

CNC machining offers high precision with typical tolerances ranging from +-0.005 mm to +-0.02 mm, making it ideal for complex shapes and tight dimensional accuracy. EDM (Electrical Discharge Machining) excels in achieving superior precision and finer tolerances, often reaching +-0.001 mm, especially useful for intricate details and hard-to-machine materials. Your choice between CNC and EDM should depend on the specific tolerance requirements and material hardness of your project.

Surface Finish and Quality Considerations

CNC machining delivers precise surface finishes with tight tolerances, ideal for complex geometries and hard materials, often achieving smooth, uniform textures through controlled cutting speeds and tooling. EDM excels in producing intricate details on difficult-to-machine materials, offering superior surface quality with minimal mechanical stress and reduced risk of deformation, particularly beneficial for delicate components requiring fine finishes. Both methods optimize surface integrity, but CNC machining prioritizes material removal efficiency while EDM focuses on achieving exceptional quality on challenging surfaces.

Cost Factors in CNC and EDM Processes

CNC machining generally incurs lower initial setup costs due to standardized tooling, whereas EDM requires specialized electrodes that can increase expenses for complex shapes. Operating costs for CNC are influenced by cutting tool wear and machining time, while EDM costs rise with electrode consumption and longer processing durations. Your choice between CNC and EDM should consider these cost factors relative to the precision and material type required for your project.

Application Areas: When to Choose CNC or EDM

CNC machining excels in high-precision manufacturing of complex parts with tight tolerances, making it ideal for automotive components, aerospace parts, and intricate molds. EDM (Electrical Discharge Machining) is preferred for hard metals, intricate contours, and delicate geometries that are difficult to machine, commonly used in tool and die making, injection molds, and aerospace turbine blades. Understanding your project's material hardness, precision needs, and geometric complexity helps determine whether CNC or EDM best suits your manufacturing application.

Future Trends in CNC Machining and EDM

Future trends in CNC machining emphasize the integration of artificial intelligence and machine learning to enhance precision and reduce cycle times, while additive manufacturing hybrid systems are expected to expand capabilities. EDM technology is advancing with faster pulses and micro-EDM techniques suited for ultra-fine detail in aerospace and medical applications. Both CNC machining and EDM are trending towards increased automation and IoT connectivity for real-time monitoring and predictive maintenance.

CNC Machining vs EDM Infographic

libmatt.com

libmatt.com