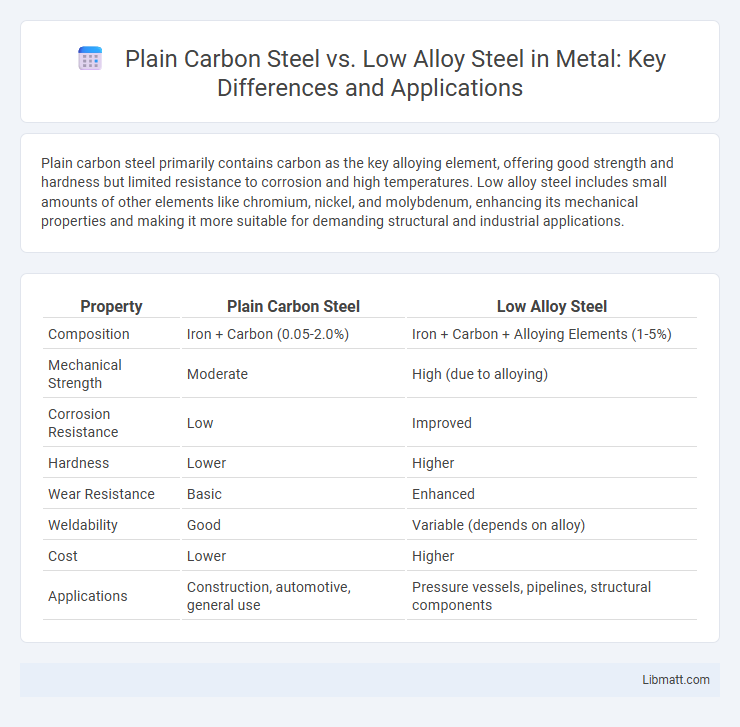

Plain carbon steel primarily contains carbon as the key alloying element, offering good strength and hardness but limited resistance to corrosion and high temperatures. Low alloy steel includes small amounts of other elements like chromium, nickel, and molybdenum, enhancing its mechanical properties and making it more suitable for demanding structural and industrial applications.

Table of Comparison

| Property | Plain Carbon Steel | Low Alloy Steel |

|---|---|---|

| Composition | Iron + Carbon (0.05-2.0%) | Iron + Carbon + Alloying Elements (1-5%) |

| Mechanical Strength | Moderate | High (due to alloying) |

| Corrosion Resistance | Low | Improved |

| Hardness | Lower | Higher |

| Wear Resistance | Basic | Enhanced |

| Weldability | Good | Variable (depends on alloy) |

| Cost | Lower | Higher |

| Applications | Construction, automotive, general use | Pressure vessels, pipelines, structural components |

Introduction to Plain Carbon Steel and Low Alloy Steel

Plain carbon steel primarily consists of iron and carbon with minimal alloying elements, offering high strength and hardness suitable for general construction and manufacturing applications. Low alloy steel contains small percentages of additional alloying elements such as chromium, nickel, and molybdenum, enhancing its mechanical properties, corrosion resistance, and weldability compared to plain carbon steel. The selection between these steels depends on performance requirements including strength, toughness, and environmental resistance for specific industrial purposes.

Chemical Composition Differences

Plain carbon steel primarily contains carbon as its main alloying element, typically ranging from 0.05% to 2.0%, with minimal amounts of other elements such as manganese, silicon, or copper. Low alloy steel includes additional alloying elements like chromium, nickel, molybdenum, and vanadium in concentrations usually between 1% and 5%, designed to enhance mechanical properties and corrosion resistance. Understanding the chemical composition differences helps you select the appropriate steel type based on performance requirements and environmental conditions.

Mechanical Properties Comparison

Plain carbon steel typically offers moderate tensile strength ranging from 400 to 550 MPa with good ductility, making it suitable for general structural applications. Low alloy steel enhances mechanical properties through added elements such as chromium, nickel, and molybdenum, resulting in higher tensile strength (up to 1000 MPa) and improved toughness, wear resistance, and fatigue strength. These improved characteristics make low alloy steels ideal for high-stress environments and demanding engineering applications.

Applications and Uses

Plain carbon steel is commonly used in construction, automotive parts, and manufacturing of tools due to its strength and affordability. Low alloy steel finds applications in aerospace, pipelines, and power generation equipment where enhanced mechanical properties and corrosion resistance are crucial. Choosing the right material for your project depends on the environmental conditions and required performance characteristics.

Cost and Availability

Plain carbon steel is generally more cost-effective and widely available due to its simple composition and mass production, making it a preferred choice for budget-conscious projects. Low alloy steel, containing additional alloying elements like chromium or molybdenum, tends to be more expensive and less readily available but offers enhanced mechanical properties and corrosion resistance. The availability of plain carbon steel in various grades and forms ensures quicker procurement and lower overall material costs compared to specialized low alloy steel variants.

Corrosion Resistance

Plain carbon steel typically exhibits lower corrosion resistance due to its higher carbon content and lack of alloying elements that form protective oxide layers. Low alloy steel contains elements such as chromium, molybdenum, and nickel, which significantly enhance its resistance to oxidation and rust in harsh environments. This improved corrosion resistance makes low alloy steel suitable for applications requiring longer service life in corrosive conditions.

Weldability and Fabrication

Plain carbon steel offers excellent weldability due to its simple chemical composition and lower carbon content, making it easier to achieve strong, defect-free welds. Low alloy steel contains various alloying elements that enhance mechanical properties but can complicate welding processes, often requiring preheating or post-weld heat treatment to prevent cracking. Fabrication of plain carbon steel involves more straightforward machining and forming techniques, whereas low alloy steel demands specialized handling to maintain material integrity during shaping and joining.

Heat Treatment and Hardening

Plain carbon steel responds well to heat treatment processes such as quenching and tempering, which enhance hardness by altering the microstructure, primarily through the formation of martensite. Low alloy steel contains additional elements like chromium, nickel, and molybdenum that improve hardenability and allow deeper hardening profiles during heat treatment, resulting in superior mechanical properties. These alloying elements also provide better resistance to softening at elevated temperatures, making low alloy steels more suitable for applications requiring enhanced strength and durability.

Advantages and Limitations

Plain carbon steel offers excellent cost-effectiveness and high strength for general applications, with good machinability and weldability. Low alloy steel provides enhanced mechanical properties such as increased toughness, corrosion resistance, and heat resistance due to added elements like chromium, nickel, and molybdenum. Your choice depends on balancing affordability and performance requirements, as plain carbon steel has limitations in extreme environments, while low alloy steel can be costlier and more complex to process.

Choosing Between Plain Carbon Steel and Low Alloy Steel

Choosing between plain carbon steel and low alloy steel depends on the specific application requirements such as strength, toughness, corrosion resistance, and weldability. Plain carbon steel offers cost-effectiveness and ease of fabrication for general use, while low alloy steel provides enhanced mechanical properties and better performance in demanding environments due to added alloying elements like chromium, nickel, and molybdenum. Selecting the appropriate steel type requires balancing factors like operating conditions, budget constraints, and required lifespan to ensure optimal material performance.

plain carbon steel vs low alloy steel Infographic

libmatt.com

libmatt.com