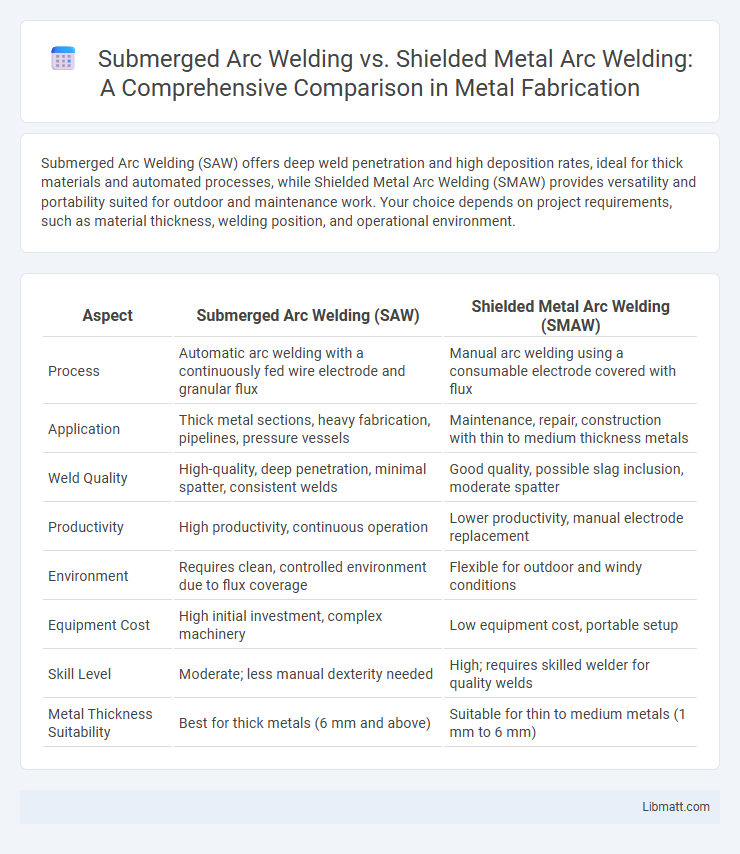

Submerged Arc Welding (SAW) offers deep weld penetration and high deposition rates, ideal for thick materials and automated processes, while Shielded Metal Arc Welding (SMAW) provides versatility and portability suited for outdoor and maintenance work. Your choice depends on project requirements, such as material thickness, welding position, and operational environment.

Table of Comparison

| Aspect | Submerged Arc Welding (SAW) | Shielded Metal Arc Welding (SMAW) |

|---|---|---|

| Process | Automatic arc welding with a continuously fed wire electrode and granular flux | Manual arc welding using a consumable electrode covered with flux |

| Application | Thick metal sections, heavy fabrication, pipelines, pressure vessels | Maintenance, repair, construction with thin to medium thickness metals |

| Weld Quality | High-quality, deep penetration, minimal spatter, consistent welds | Good quality, possible slag inclusion, moderate spatter |

| Productivity | High productivity, continuous operation | Lower productivity, manual electrode replacement |

| Environment | Requires clean, controlled environment due to flux coverage | Flexible for outdoor and windy conditions |

| Equipment Cost | High initial investment, complex machinery | Low equipment cost, portable setup |

| Skill Level | Moderate; less manual dexterity needed | High; requires skilled welder for quality welds |

| Metal Thickness Suitability | Best for thick metals (6 mm and above) | Suitable for thin to medium metals (1 mm to 6 mm) |

Introduction to Submerged Arc Welding and Shielded Metal Arc Welding

Submerged Arc Welding (SAW) utilizes a continuously fed consumable electrode and a blanket of granular flux to produce deep, high-quality welds ideal for thick materials and heavy fabrication. Shielded Metal Arc Welding (SMAW), also known as stick welding, employs a consumable electrode coated in flux to create a protective gas shield, making it versatile and suitable for various environments, including outdoor and field work. Understanding the distinctions in equipment, shielding methods, and typical applications helps you select the appropriate welding process for your specific project requirements.

Process Overview: SAW vs SMAW

Submerged Arc Welding (SAW) utilizes a continuously fed consumable electrode and a blanket of granular flux, creating a strong, high-quality weld with deep penetration and minimal spatter. Shielded Metal Arc Welding (SMAW), also known as stick welding, employs a consumable electrode coated with flux, which melts to form a protective gas shield and slag, ideal for versatility and outdoor applications. SAW is highly automated and suited for thick materials, while SMAW offers portability and ease of use in varied environments.

Equipment and Setup Requirements

Submerged Arc Welding requires a specialized setup including a continuous wire feed, a flux delivery system, and a welding power source capable of providing high amperage for deep weld penetration. Shielded Metal Arc Welding uses a simpler setup consisting of a portable welding power supply, electrode holder, and shielding electrodes, making it more adaptable to field conditions. The equipment for Submerged Arc Welding is generally more complex and suited for automated or semi-automated processes, whereas Shielded Metal Arc Welding favors manual operation with minimal gear.

Electrode Types and Consumables

Submerged Arc Welding (SAW) employs continuously fed tubular or solid wire electrodes paired with granular flux that protects the weld pool and stabilizes the arc, enhancing deposition rates and weld quality in heavy industrial applications. Shielded Metal Arc Welding (SMAW) utilizes consumable stick electrodes coated with flux, which melts during welding to provide shielding gas and slag, making it versatile for outdoors and portable jobs. SAW's flux and wire combinations are optimized for deep penetration and high-speed welding, whereas SMAW electrodes come in various classifications (E6010, E7018) tailored for different metals and positions, emphasizing repair and maintenance tasks.

Welding Speed and Productivity

Submerged Arc Welding (SAW) offers significantly higher welding speeds and productivity compared to Shielded Metal Arc Welding (SMAW) due to its continuous wire feed and automatic operation. The SAW process enables deep weld penetration and high deposition rates, making it ideal for large, heavy-duty projects requiring efficient material build-up. Your choice between SAW and SMAW will impact project timelines, with SAW providing faster completion on thick materials and long weld seams.

Weld Quality and Appearance

Submerged Arc Welding (SAW) consistently produces superior weld quality with deeper penetration, minimal spatter, and a smooth, uniform bead appearance due to its continuous weld pool protection under a flux layer. In contrast, Shielded Metal Arc Welding (SMAW) often results in more visible slag and slag inclusions, leading to a rougher surface and requiring more post-weld cleaning to achieve aesthetic appeal. The controlled environment in SAW reduces defects and enhances structural integrity, making it preferable for applications demanding high-quality, visually consistent welds.

Application Areas and Industry Uses

Submerged Arc Welding (SAW) is extensively utilized in heavy industries such as shipbuilding, pipeline construction, and structural steel fabrication due to its high deposition rate and deep weld penetration. Shielded Metal Arc Welding (SMAW) remains preferred in maintenance, repair, and fieldwork applications within construction, offshore, and manufacturing industries because of its versatility and portability. SAW excels in automated, large-scale production environments, while SMAW suits diverse welding positions and materials with lower equipment investment.

Cost Considerations and Efficiency

Submerged Arc Welding (SAW) offers higher efficiency with faster deposition rates and deeper weld penetration, reducing overall labor costs compared to Shielded Metal Arc Welding (SMAW). SAW requires a higher initial investment due to specialized equipment and consumables, but its automated process lowers operating expenses and increases productivity. Your choice should weigh upfront costs against long-term savings and project scale, as SMAW remains cost-effective for smaller or maintenance tasks.

Safety and Environmental Factors

Submerged Arc Welding (SAW) produces fewer harmful fumes and offers greater protection to operators due to the welding arc being submerged under a layer of flux, significantly reducing exposure to ultraviolet light and sparks. Shielded Metal Arc Welding (SMAW) generates more smoke and ultraviolet radiation, posing higher risks of respiratory issues and eye damage without proper protective gear. SAW's minimal spatter and lower emission rate contribute to a cleaner work environment, enhancing safety and reducing environmental impact compared to SMAW.

Choosing the Right Welding Process

Submerged Arc Welding (SAW) offers deep weld penetration and high deposition rates, making it ideal for thick materials and long, straight welds, while Shielded Metal Arc Welding (SMAW) provides versatility and portability for diverse positions and maintenance tasks. Your choice depends on factors like material thickness, welding position, production volume, and accessibility; SAW excels in automated, high-speed applications, whereas SMAW suits fieldwork with limited equipment. Evaluating these parameters ensures optimal efficiency, weld quality, and cost-effectiveness for your specific project requirements.

Submerged Arc Welding vs Shielded Metal Arc Welding Infographic

libmatt.com

libmatt.com