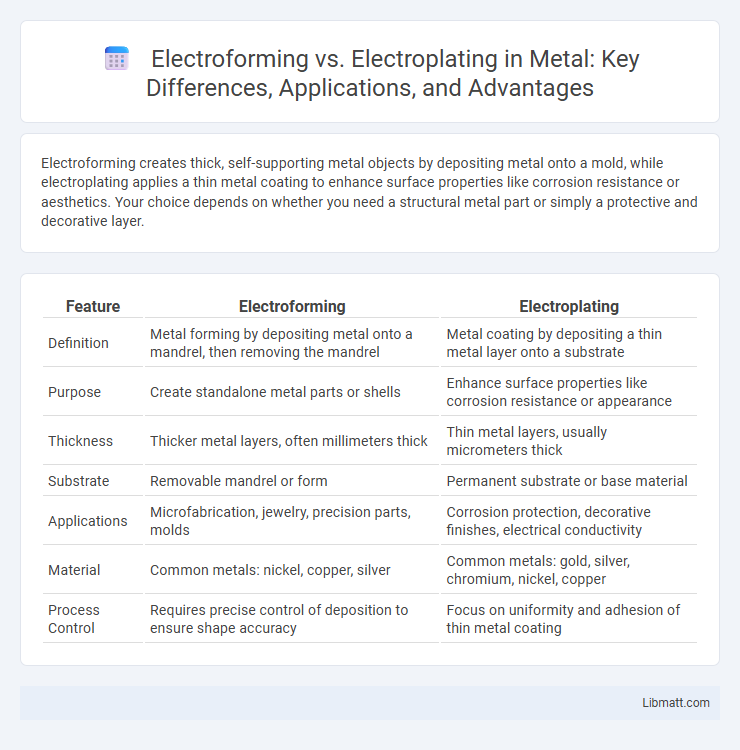

Electroforming creates thick, self-supporting metal objects by depositing metal onto a mold, while electroplating applies a thin metal coating to enhance surface properties like corrosion resistance or aesthetics. Your choice depends on whether you need a structural metal part or simply a protective and decorative layer.

Table of Comparison

| Feature | Electroforming | Electroplating |

|---|---|---|

| Definition | Metal forming by depositing metal onto a mandrel, then removing the mandrel | Metal coating by depositing a thin metal layer onto a substrate |

| Purpose | Create standalone metal parts or shells | Enhance surface properties like corrosion resistance or appearance |

| Thickness | Thicker metal layers, often millimeters thick | Thin metal layers, usually micrometers thick |

| Substrate | Removable mandrel or form | Permanent substrate or base material |

| Applications | Microfabrication, jewelry, precision parts, molds | Corrosion protection, decorative finishes, electrical conductivity |

| Material | Common metals: nickel, copper, silver | Common metals: gold, silver, chromium, nickel, copper |

| Process Control | Requires precise control of deposition to ensure shape accuracy | Focus on uniformity and adhesion of thin metal coating |

Introduction to Electroforming and Electroplating

Electroforming involves depositing metal onto a mold to create a precise, standalone metal object, often used for intricate or delicate designs requiring high fidelity. Electroplating, by contrast, applies a thin metal coating to the surface of a different substrate to enhance corrosion resistance, appearance, or conductivity without altering the base structure. Both processes utilize electrochemical deposition but serve distinct purposes in manufacturing and surface engineering.

Key Differences Between Electroforming and Electroplating

Electroforming creates a thick, self-supporting metal structure by depositing metal onto a mold, while electroplating applies a thin metal layer onto a conductive surface to enhance appearance or corrosion resistance. Electroforming involves building metal thickness up to several millimeters, making it ideal for producing intricate, standalone metal parts, whereas electroplating typically deposits micrometer-thin layers for surface protection or decoration. The key difference lies in electroforming's ability to produce metal objects through mold shaping versus electroplating's role in coating existing objects with a metal film.

How Electroforming Works: Process Overview

Electroforming works by depositing metal onto a conductive or patterned substrate through an electrolytic bath, creating a precise and durable metal layer that replicates the mold's fine details. This process begins with a mandrel or form, which is coated with a thin conductive layer before immersion in a metal ion solution where electric current causes metal ions to adhere and build up progressively. Your ability to control thickness and shape through electroforming surpasses electroplating, which typically produces thinner, less structurally integral metal coatings.

How Electroplating Works: Process Overview

Electroplating involves depositing a thin layer of metal onto a conductive surface through an electrolytic cell, where the object to be plated acts as the cathode and the metal to be coated serves as the anode. The process starts with the immersion of the workpiece in an electrolytic bath containing metal ions, which are reduced and deposited onto the surface by applying an electric current. This technique enhances properties such as corrosion resistance, surface hardness, and aesthetic appeal without significantly altering the object's dimensions.

Material Compatibility in Electroforming vs Electroplating

Electroforming offers superior material compatibility by allowing the deposition of metals onto non-conductive substrates through conductive coatings, making it ideal for intricate or delicate materials like plastics and glass. Electroplating primarily requires conductive substrates, limiting its use to metals or pre-treated surfaces. Your choice depends on the substrate material and the desired precision and adhesion for the final product.

Applications of Electroforming

Electroforming is widely used in precision industries such as aerospace, electronics, and medical device manufacturing due to its ability to create complex, high-strength metal parts with exceptional thickness control and surface detail. This technique enables the production of lightweight structural components, intricate molds, and decorative objects that require minimal post-processing. Your projects benefit from electroforming's capacity to replicate fine features and durable metal layers, distinguishing it from conventional electroplating which primarily provides thin, protective, or decorative coatings.

Applications of Electroplating

Electroplating is widely used in industries such as automotive, electronics, and jewelry to enhance corrosion resistance, improve aesthetic appeal, and increase surface hardness of metal parts. It provides a thin, uniform metallic coating that protects components from wear and oxidation, making it essential for manufacturing reliable electrical connectors and decorative finishes. Your products benefit from electroplating's precision and durability, ensuring long-lasting performance and enhanced functionality.

Advantages and Disadvantages of Electroforming

Electroforming offers superior precision and the ability to create complex, high-strength metal parts with excellent dimensional accuracy, making it ideal for intricate designs and custom applications. However, it can be costlier and slower than electroplating, requiring specialized equipment and skilled operation, which may limit its use for large-scale or simple coating tasks. Your choice should depend on whether you need detailed metal structures or a thin, decorative surface layer.

Advantages and Disadvantages of Electroplating

Electroplating offers advantages such as enhanced corrosion resistance, improved aesthetic appeal, and increased surface hardness, making it ideal for decorative and protective coatings. However, electroplating presents disadvantages including limited thickness control, potential environmental hazards from toxic chemicals, and the necessity for precise process parameters to avoid defects like peeling or uneven coating. Understanding these factors helps you decide when electroplating is suitable compared to electroforming, which builds thicker, more uniform metal parts but with longer processing times.

Choosing Between Electroforming and Electroplating

Choosing between electroforming and electroplating depends on your project's requirements for precision and thickness. Electroforming builds up thick, durable metal layers ideal for creating complex, standalone metal parts, while electroplating deposits a thin metallic coating to enhance surface properties like corrosion resistance or aesthetics. Consider electroforming when you need structural metal components and electroplating when surface finish or conductivity improvements are the primary goal.

Electroforming vs electroplating Infographic

libmatt.com

libmatt.com