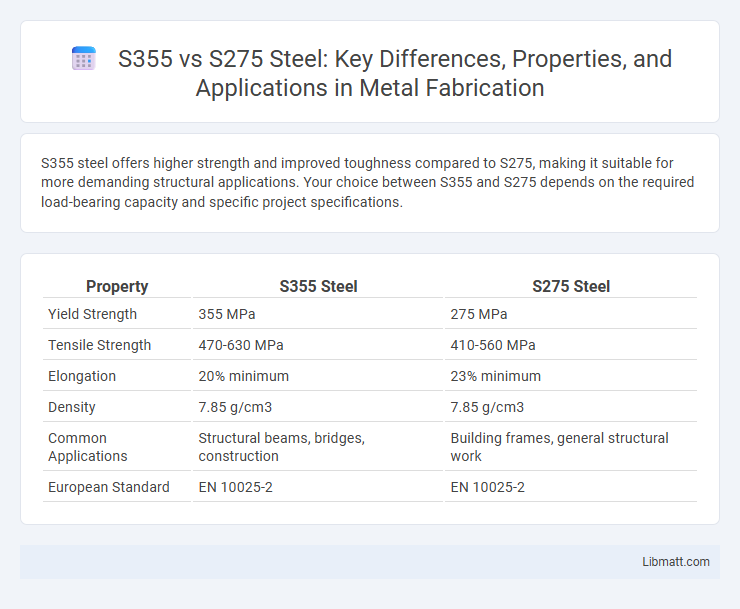

S355 steel offers higher strength and improved toughness compared to S275, making it suitable for more demanding structural applications. Your choice between S355 and S275 depends on the required load-bearing capacity and specific project specifications.

Table of Comparison

| Property | S355 Steel | S275 Steel |

|---|---|---|

| Yield Strength | 355 MPa | 275 MPa |

| Tensile Strength | 470-630 MPa | 410-560 MPa |

| Elongation | 20% minimum | 23% minimum |

| Density | 7.85 g/cm3 | 7.85 g/cm3 |

| Common Applications | Structural beams, bridges, construction | Building frames, general structural work |

| European Standard | EN 10025-2 | EN 10025-2 |

Introduction to S355 and S275 Steel

S355 and S275 steels are prominent structural steel grades defined under the EN 10025 standard, widely used in construction and engineering projects. S355 steel offers a higher yield strength of 355 N/mm2, making it suitable for heavy-duty applications requiring enhanced load-bearing capacity, whereas S275 steel has a yield strength of 275 N/mm2, ideal for lighter structural demands. Understanding the mechanical properties and applications of these steels ensures your project meets safety and performance criteria efficiently.

Chemical Composition Comparison

S355 steel contains a higher amount of carbon, typically around 0.20%, compared to S275 steel, which usually has about 0.22% maximum, enhancing S355's strength and weldability. The manganese content in S355 ranges from 1.00% to 1.60%, slightly higher than the 1.00% minimum found in S275, contributing to improved toughness and hardenability. Both grades maintain low sulfur and phosphorus levels to ensure better mechanical properties and structural performance in engineering applications.

Mechanical Properties Overview

S355 steel offers higher tensile strength, typically around 510-680 MPa, compared to S275 steel's 410-560 MPa, making it more suitable for demanding structural applications. Both grades exhibit good weldability and toughness, but S355 provides improved yield strength at 355 MPa versus S275's 275 MPa, enhancing load-bearing capacity. Your choice between S355 and S275 should consider the specific mechanical performance requirements of your project to ensure optimal strength and durability.

Yield Strength Differences

S355 steel offers a higher yield strength of approximately 355 MPa compared to S275 steel, which typically has a yield strength around 275 MPa, making S355 more suitable for structural applications requiring greater load-bearing capacity. The increased yield strength of S355 allows your projects to use thinner sections while maintaining strength, resulting in potential material savings. Understanding these differences is crucial when selecting steel grades for construction, ensuring optimal safety and performance.

Tensile Strength Analysis

S355 steel exhibits a higher tensile strength, typically around 510-680 MPa, compared to S275 steel, which ranges from 410-560 MPa. This increased tensile strength makes S355 more suitable for applications requiring greater load-bearing capacity and enhanced durability. The alloy composition and microstructure differences contribute to S355's superior mechanical performance in structural engineering scenarios.

Applications and Usage Sectors

S355 steel is commonly used in structural engineering, heavy machinery, and construction due to its higher tensile strength and better weldability, making it ideal for load-bearing applications. S275 steel finds frequent application in general engineering, bridges, and shipbuilding where moderate strength and good ductility are essential. Your choice between S355 and S275 should align with the specific strength requirements and environmental conditions of your project sector.

Weldability and Fabrication

S355 steel offers superior weldability compared to S275 due to its higher strength and improved chemical composition, allowing for easier handling during fabrication. Both steels exhibit good machinability, but S355's enhanced toughness reduces the risk of cracking in welded joints, making it preferred for structural applications requiring increased strength. Fabricators favor S355 for heavy-duty projects where welding precision and durability are critical.

Cost Comparison and Availability

S275 steel generally costs less than S355 steel due to its lower tensile strength and less demanding manufacturing process, making it a budget-friendly option for projects with moderate strength requirements. S355 steel, while more expensive, provides higher durability and better performance in structural applications, which can justify the added cost depending on your engineering needs. Both materials are widely available in standard forms and sizes, but S275 might be easier to source quickly in certain regions because of its broader usage in general construction.

Standards and Certification

S355 and S275 steel grades are classified under the EN 10025 standard, which specifies technical delivery conditions for structural steel. S355 steel offers higher tensile strength and better mechanical properties compared to S275, making it suitable for more demanding construction projects. Your choice between these grades should consider the certification requirements and compliance with relevant EN standards to ensure material quality and performance.

Choosing Between S355 and S275 Steel

Choosing between S355 and S275 steel depends on the mechanical strength and application requirements of your project. S355 offers higher yield strength of 355 MPa compared to S275's 275 MPa, making it more suitable for heavy structural components and construction where greater load-bearing capacity is essential. Your decision should also consider factors like weldability, toughness, and cost-efficiency, as S275 may be preferred for lighter structures requiring less strength.

S355 vs S275 steel Infographic

libmatt.com

libmatt.com