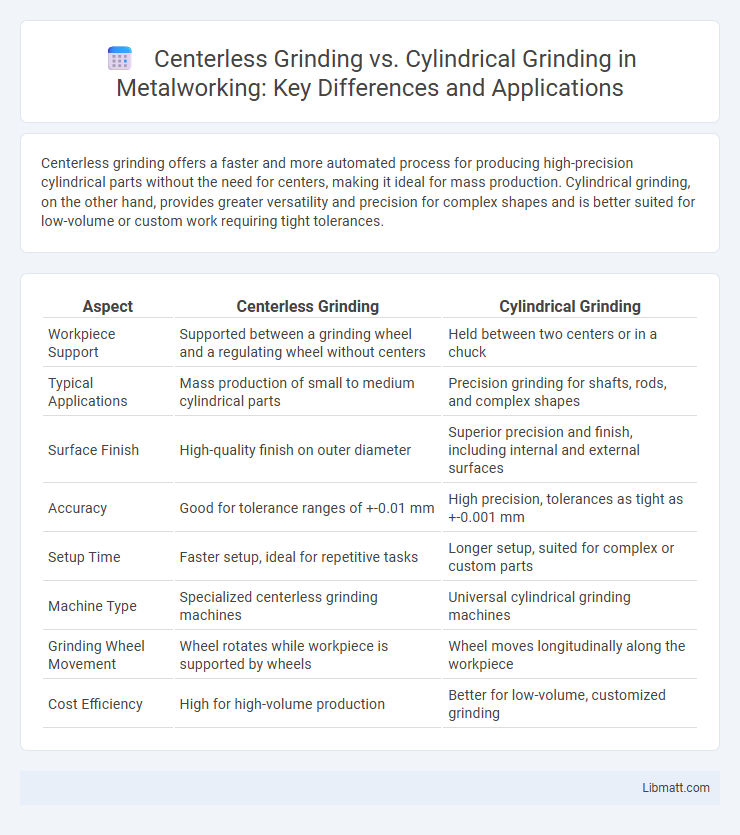

Centerless grinding offers a faster and more automated process for producing high-precision cylindrical parts without the need for centers, making it ideal for mass production. Cylindrical grinding, on the other hand, provides greater versatility and precision for complex shapes and is better suited for low-volume or custom work requiring tight tolerances.

Table of Comparison

| Aspect | Centerless Grinding | Cylindrical Grinding |

|---|---|---|

| Workpiece Support | Supported between a grinding wheel and a regulating wheel without centers | Held between two centers or in a chuck |

| Typical Applications | Mass production of small to medium cylindrical parts | Precision grinding for shafts, rods, and complex shapes |

| Surface Finish | High-quality finish on outer diameter | Superior precision and finish, including internal and external surfaces |

| Accuracy | Good for tolerance ranges of +-0.01 mm | High precision, tolerances as tight as +-0.001 mm |

| Setup Time | Faster setup, ideal for repetitive tasks | Longer setup, suited for complex or custom parts |

| Machine Type | Specialized centerless grinding machines | Universal cylindrical grinding machines |

| Grinding Wheel Movement | Wheel rotates while workpiece is supported by wheels | Wheel moves longitudinally along the workpiece |

| Cost Efficiency | High for high-volume production | Better for low-volume, customized grinding |

Introduction to Centerless and Cylindrical Grinding

Centerless grinding and cylindrical grinding are precision machining processes used to finish round parts with high accuracy and surface quality. Centerless grinding removes material without the need for workpiece centers, using a grinding wheel and regulating wheel to control the part's rotation and feed. Cylindrical grinding, on the other hand, requires mounting the workpiece between centers or in a chuck, allowing the grinding wheel to achieve precise diameter and surface finish on external or internal cylindrical surfaces.

Fundamental Principles of Centerless Grinding

Centerless grinding operates by supporting the workpiece between a grinding wheel and a regulating wheel, eliminating the need for individual workpiece fixtures, and allowing continuous feed through the machine. The process relies on the precise balance of rotational speeds and angles of the wheels to ensure accurate material removal and dimensional control. Unlike cylindrical grinding, centerless grinding achieves high throughput for mass production while maintaining consistent roundness and surface finish.

Fundamental Principles of Cylindrical Grinding

Cylindrical grinding operates on the principle of rotating the workpiece against a grinding wheel to achieve precise dimensional accuracy and surface finish. The workpiece is held between centers or in a chuck while the grinding wheel, mounted on a spindle, removes material through controlled abrasion. This method allows for grinding external or internal cylindrical surfaces with consistent concentricity and tight tolerances.

Key Differences Between Centerless and Cylindrical Grinding

Centerless grinding differs from cylindrical grinding primarily in workpiece support; it uses a regulating wheel and a work rest blade instead of centers, enabling continuous feeding and higher throughput. Cylindrical grinding supports the workpiece between centers or on a chuck, offering precise control for complex shapes and tighter tolerances. Centerless grinding excels in high-volume production of uniform parts, while cylindrical grinding is preferred for detailed machining and finishing of external cylindrical surfaces.

Advantages of Centerless Grinding

Centerless grinding offers higher production rates and improved efficiency by eliminating the need for workpiece clamping, allowing continuous feeding of smaller cylindrical parts. Its unique support system reduces setup times and enhances dimensional consistency, making it ideal for mass production of precision components such as bearing races and pins. Centerless grinding also enables tighter tolerances and better surface finishes on complex geometries compared to cylindrical grinding.

Advantages of Cylindrical Grinding

Cylindrical grinding offers precise dimensional control and surface finish quality, making it ideal for parts requiring tight tolerances and consistent roundness. The ability to grind both internal and external surfaces enhances versatility, particularly for complex components such as shafts and rollers. Its stability and support provided by centers or chucks reduce vibration and improve accuracy compared to centerless grinding.

Applications of Centerless vs Cylindrical Grinding

Centerless grinding is widely used for high-volume production of small, consistent parts such as shafts, pins, and tubes, where rapid throughput and minimal setup are essential. Cylindrical grinding suits applications requiring precision machining of external or internal surfaces on larger, complex components like engine parts, spindles, and hydraulic cylinders, delivering superior surface finish and dimensional accuracy. Your choice depends on the part geometry, production volume, and tolerance specifications.

Surface Finish and Precision Comparison

Centerless grinding typically delivers superior surface finish and tight dimensional tolerances due to the continuous, stable support of the workpiece between the grinding wheel and regulating wheel. Cylindrical grinding offers higher precision in complex geometries and can achieve finer surface finishes on intricate parts by controlling rotation and movement independently. Both methods excel in precision, but centerless grinding is often preferred for high-volume production with uniform finishes on simpler shapes.

Choosing the Right Grinding Method for Your Project

Centerless grinding offers high-speed, precise material removal for mass production of cylindrical parts without the need for workpiece mounting, making it ideal for uniform, small-diameter components. Cylindrical grinding provides greater versatility and precision for complex shapes, requiring the workpiece to be held securely between centers for processing larger, irregular parts. Your choice depends on factors such as part geometry, production volume, and required tolerances to optimize efficiency and surface finish.

Conclusion: Centerless vs Cylindrical Grinding

Centerless grinding offers higher production rates and consistent dimensional accuracy for cylindrical parts, making it ideal for mass manufacturing of small and medium-sized components. Cylindrical grinding provides superior precision and surface finish for complex geometries, suitable for custom or low-volume work requiring tight tolerances. Understanding your specific application requirements ensures you choose the most effective grinding method for optimal results.

centerless grinding vs cylindrical grinding Infographic

libmatt.com

libmatt.com