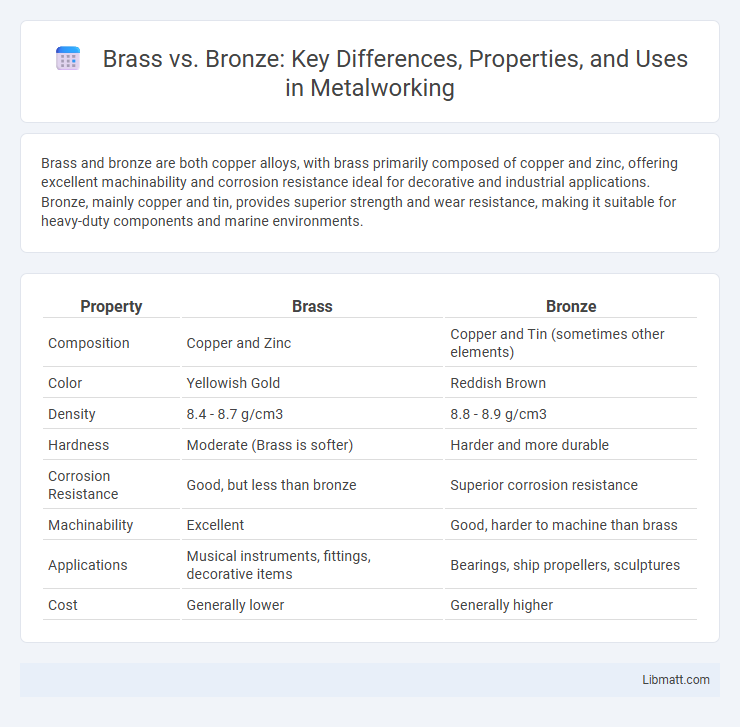

Brass and bronze are both copper alloys, with brass primarily composed of copper and zinc, offering excellent machinability and corrosion resistance ideal for decorative and industrial applications. Bronze, mainly copper and tin, provides superior strength and wear resistance, making it suitable for heavy-duty components and marine environments.

Table of Comparison

| Property | Brass | Bronze |

|---|---|---|

| Composition | Copper and Zinc | Copper and Tin (sometimes other elements) |

| Color | Yellowish Gold | Reddish Brown |

| Density | 8.4 - 8.7 g/cm3 | 8.8 - 8.9 g/cm3 |

| Hardness | Moderate (Brass is softer) | Harder and more durable |

| Corrosion Resistance | Good, but less than bronze | Superior corrosion resistance |

| Machinability | Excellent | Good, harder to machine than brass |

| Applications | Musical instruments, fittings, decorative items | Bearings, ship propellers, sculptures |

| Cost | Generally lower | Generally higher |

Introduction: Brass vs Bronze

Brass and bronze are two widely used copper alloys with distinct compositions and applications. Brass primarily consists of copper and zinc, offering excellent machinability and corrosion resistance, making it ideal for decorative and mechanical purposes. Bronze, composed mainly of copper and tin, exhibits superior strength and resistance to wear and saltwater corrosion, often used in marine and industrial environments.

Historical Background of Brass and Bronze

Brass, an alloy primarily of copper and zinc, has been utilized since at least 1000 BCE, serving ancient civilizations like the Greeks and Romans for decorative and practical items due to its malleability and acoustic properties. Bronze, composed mainly of copper and tin, dates back even further to around 3300 BCE during the Bronze Age, revolutionizing tools, weapons, and art with its superior hardness and corrosion resistance. Your understanding of these metals enhances appreciation for their historic role in technological and cultural advancements across ancient societies.

Chemical Composition: Key Differences

Brass primarily consists of copper and zinc, typically containing around 55-95% copper with the remainder being zinc, whereas bronze is mainly an alloy of copper and tin, usually comprising about 88% copper and 12% tin. The key chemical difference lies in zinc being the major alloying element in brass, which contributes to its ductility and corrosion resistance, while tin in bronze enhances hardness and wear resistance. Other elements such as lead, phosphorus, or aluminum may be added in small amounts to both alloys to tailor their mechanical and chemical properties.

Physical Properties Comparison

Brass exhibits higher malleability and excellent corrosion resistance, making it ideal for applications requiring complex shapes and durability. Bronze, with greater tensile strength and superior wear resistance, suits heavy-duty uses like bearings and marine hardware. Understanding these physical property differences helps optimize your material choice for specific mechanical and environmental demands.

Common Uses and Applications

Brass, an alloy of copper and zinc, is commonly used in musical instruments, plumbing fixtures, and decorative items due to its excellent machinability and corrosion resistance. Bronze, consisting primarily of copper and tin, is favored in applications such as ship propellers, bearings, and sculptures for its durability, resistance to metal fatigue, and ability to withstand harsh marine environments. Both alloys are essential in manufacturing and art, but their distinct mechanical properties and corrosion resistance dictate their specific industrial and artistic uses.

Corrosion Resistance and Durability

Brass offers moderate corrosion resistance, making it suitable for indoor applications where exposure to moisture is limited, while bronze exhibits superior corrosion resistance, especially in marine environments due to its higher copper and tin content. The durability of bronze surpasses that of brass, as it is harder and more resistant to wear and deformation under stress, which makes bronze ideal for heavy-duty components and outdoor fixtures. Your choice between brass and bronze should consider the environmental conditions and mechanical requirements to ensure long-lasting performance.

Workability and Machinability

Brass offers superior workability due to its lower melting point and softer composition, making it easier to cut, shape, and form with standard machining tools. Bronze, being harder and more wear-resistant, presents more challenge in machining but provides better durability in finished parts. The machinability rating of brass typically ranges from 85 to 95 on the machinability index, whereas bronze scores lower, around 40 to 60, reflecting its increased difficulty during machining processes.

Cost and Availability

Brass generally has a lower cost and higher availability compared to bronze due to its simpler alloy composition, primarily copper and zinc. Bronze, composed of copper and tin, tends to be more expensive because tin is less abundant and more costly. Brass is widely used in applications requiring cost-efficiency and easy sourcing, while bronze is preferred when corrosion resistance and durability justify its higher price.

Aesthetic Differences in Appearance

Brass features a bright yellow-gold hue with a smooth, shiny surface that enhances its appeal in decorative applications, while bronze exhibits a deeper, reddish-brown tone with a slightly matte finish that develops a natural patina over time. The subtle variations in alloy composition influence the metals' color intensity and texture, making brass preferred for a polished, modern look and bronze favored for a rustic, antique aesthetic. These aesthetic differences impact their use in design, jewelry, and architectural elements where visual appearance is critical.

Choosing the Right Alloy

Choosing the right alloy depends on your project's specific needs for strength, corrosion resistance, and appearance. Brass, composed primarily of copper and zinc, offers excellent machinability and a bright gold-like finish, making it ideal for decorative applications and electrical components. Bronze, an alloy of copper and tin, provides superior corrosion resistance and durability, especially in marine environments, making it suitable for heavy-duty machinery and sculptures.

Brass vs Bronze Infographic

libmatt.com

libmatt.com