Universal Beam (UB) and I Beam differ mainly in flange width and thickness; Universal Beams have wider flanges that provide better load distribution and stability, making them ideal for structural applications requiring higher strength. Your choice depends on the specific load-bearing needs and design requirements of your project, with I Beams often preferred for lighter, more straightforward structures due to their narrower flanges.

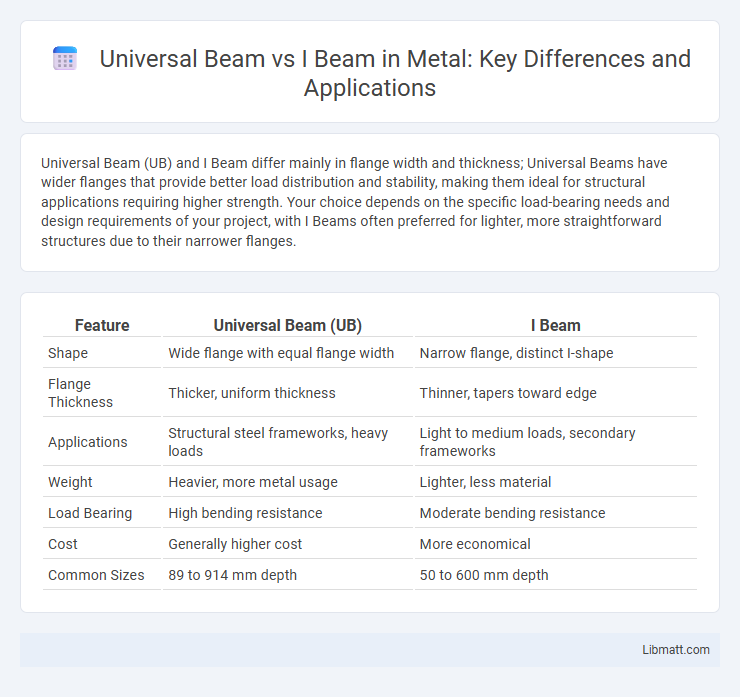

Table of Comparison

| Feature | Universal Beam (UB) | I Beam |

|---|---|---|

| Shape | Wide flange with equal flange width | Narrow flange, distinct I-shape |

| Flange Thickness | Thicker, uniform thickness | Thinner, tapers toward edge |

| Applications | Structural steel frameworks, heavy loads | Light to medium loads, secondary frameworks |

| Weight | Heavier, more metal usage | Lighter, less material |

| Load Bearing | High bending resistance | Moderate bending resistance |

| Cost | Generally higher cost | More economical |

| Common Sizes | 89 to 914 mm depth | 50 to 600 mm depth |

Overview of Universal Beam and I Beam

Universal Beams and I Beams are structural steel sections with distinct shapes and applications; Universal Beams feature wider flanges and are commonly used in construction for their superior load-bearing capacity, while I Beams have narrower flanges suited for lighter structural tasks. The design of Universal Beams allows for better resistance to bending in multiple directions, enhancing stability in large-span frameworks. Understanding the differences between these beams will help you select the appropriate steel section for your engineering or architectural projects.

Key Design Differences

Universal beams and I beams differ primarily in flange width and thickness; universal beams feature wider, more uniformly thick flanges designed for greater load distribution. I beams have narrower flanges with varying thickness, optimizing them for bending resistance in one direction. Your choice depends on specific structural requirements, as universal beams offer enhanced stability and load capacity in multi-directional applications compared to standard I beams.

Structural Applications

Universal beams (UB) feature equal flange widths on both sides, providing enhanced resistance to bending and torsional forces, making them ideal for structural applications requiring strong load-bearing capabilities in steel construction such as bridges, buildings, and frameworks. I beams have narrower flanges and are primarily designed to support vertical loads with less resistance to twisting, commonly used in lighter construction tasks like floor joists, and roof supports. Your choice between universal beam and I beam depends on the specific load distribution and torsional stability required in your structural project.

Material Specifications

Universal Beams (UB) and I Beams are primarily fabricated from structural steel complying with standards such as ASTM A992 or EN 10025, ensuring high tensile strength and durability. Universal Beams feature parallel flanges with consistent thickness, enhancing load distribution and conforming to specifications like BS EN 10365 for precise dimensional accuracy. I Beams typically have tapered flanges and are manufactured according to ASTM A36 or A572 standards, optimizing their performance in bending applications while maintaining reliable structural integrity.

Load-Bearing Capacity Comparison

Universal beams typically offer higher load-bearing capacity compared to I beams due to their wider flange and uniform thickness, which distribute stress more evenly across the structure. I beams have narrower flanges and are optimized for bending along one axis, making them effective for specific load conditions but less versatile than universal beams for heavy, multidirectional loads. Structural engineers often prefer universal beams in building frameworks where maximum strength and stability against varying forces are crucial.

Versatility in Construction Projects

Universal Beams offer greater versatility in construction projects due to their wider flanges and higher load-bearing capacity, making them suitable for both structural and architectural applications. I Beams, with narrower flanges, are often preferred for lighter loads and specific beam applications where weight savings are crucial. Your choice between Universal Beam and I Beam will depend on the specific load requirements and design flexibility needed for your construction project.

Manufacturing Processes

Universal beams and I beams differ primarily in their manufacturing processes, with universal beams typically produced through hot rolling, allowing for precise dimensions and consistent quality. I beams, while sometimes hot rolled, may also be fabricated by welding plates together for custom sizes and applications. Your choice between the two depends on the specific structural requirements and cost considerations influenced by these manufacturing methods.

Cost Comparison

Universal Beams typically cost more than I Beams due to their wider flange width and greater load-bearing capacity, which require more raw material. I Beams are generally more economical for projects with lighter structural demands, offering a cost-effective solution without compromising basic strength. Budget considerations should weigh the specific structural requirements to determine whether the higher initial investment in Universal Beams yields long-term value through enhanced performance and durability.

Advantages and Disadvantages

Universal Beams offer high load-bearing capacity and excellent resistance to bending, making them ideal for heavy structural applications, but they tend to be heavier and more expensive than I Beams. I Beams provide a more economical option with lighter weight and ease of fabrication, though they may not support as much weight or resist bending forces as effectively as Universal Beams. Your choice depends on balancing structural requirements with budget constraints and weight considerations.

Choosing the Right Beam for Your Project

Choosing the right beam for your project depends on load requirements and design constraints, with Universal Beams (UB) offering a wider flange suitable for heavier loads and architectural applications. I Beams, featuring narrower flanges, are ideal for lighter loads and simpler structural needs. Understanding your structural demands ensures your choice optimizes strength, cost, and installation efficiency.

Universal Beam vs I Beam Infographic

libmatt.com

libmatt.com