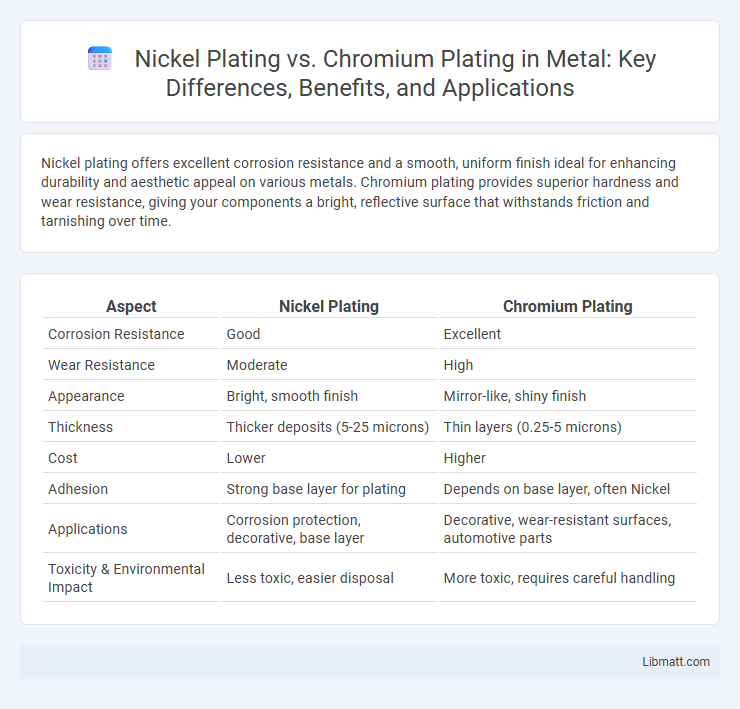

Nickel plating offers excellent corrosion resistance and a smooth, uniform finish ideal for enhancing durability and aesthetic appeal on various metals. Chromium plating provides superior hardness and wear resistance, giving your components a bright, reflective surface that withstands friction and tarnishing over time.

Table of Comparison

| Aspect | Nickel Plating | Chromium Plating |

|---|---|---|

| Corrosion Resistance | Good | Excellent |

| Wear Resistance | Moderate | High |

| Appearance | Bright, smooth finish | Mirror-like, shiny finish |

| Thickness | Thicker deposits (5-25 microns) | Thin layers (0.25-5 microns) |

| Cost | Lower | Higher |

| Adhesion | Strong base layer for plating | Depends on base layer, often Nickel |

| Applications | Corrosion protection, decorative, base layer | Decorative, wear-resistant surfaces, automotive parts |

| Toxicity & Environmental Impact | Less toxic, easier disposal | More toxic, requires careful handling |

Introduction to Nickel and Chromium Plating

Nickel plating provides excellent corrosion resistance, enhanced hardness, and a smooth, decorative finish ideal for automotive parts and electronics. Chromium plating offers superior hardness, high wear resistance, and a reflective, mirror-like surface commonly used in industrial tools and decorative applications. Both processes involve electroplating metal substrates to improve durability and appearance, but nickel plating tends to be more versatile in corrosion protection compared to the high hardness and aesthetic appeal of chromium plating.

Composition and Chemical Properties

Nickel plating primarily consists of a thin layer of nickel metal deposited through an electrolytic process, characterized by high corrosion resistance and excellent hardness due to its ferromagnetic and ductile nature. Chromium plating involves depositing a thin layer of chromium metal, which provides superior hardness, wear resistance, and a distinct bright, reflective finish attributed to chromium's inertness and resistance to oxidation. Both coatings enhance substrate durability, but nickel plating offers better corrosion resistance in mildly acidic environments, whereas chromium plating excels in abrasion resistance and high-temperature stability.

Aesthetic Differences: Appearance and Finish

Nickel plating offers a smooth, lustrous finish with a warm, slightly yellowish tone that enhances the underlying metal, making it popular for decorative applications requiring a classic, elegant look. Chromium plating provides a highly reflective, mirror-like surface with a cool, bluish-silver hue, known for its superior hardness and corrosion resistance, often used for automotive trim and industrial parts. The aesthetic differences between nickel and chromium plating hinge on their color warmth and shine intensity, with nickel delivering a softer glow while chromium achieves a sharper, more striking brilliance.

Corrosion Resistance: A Comparative Analysis

Nickel plating offers excellent corrosion resistance by forming a dense, protective barrier that effectively inhibits oxidation and rust, especially in moderate environments. Chromium plating provides superior hardness and a more durable surface with enhanced corrosion resistance in harsh or acidic conditions due to its passivating chromium oxide layer. Choosing between nickel and chromium plating depends on the specific environmental exposure and performance requirements of the application.

Durability and Wear Resistance

Nickel plating offers excellent corrosion resistance and moderate wear resistance, making it suitable for decorative and functional applications where a smooth, corrosion-proof surface is needed. Chromium plating provides superior hardness and wear resistance, significantly enhancing the durability of parts exposed to heavy friction and abrasive conditions. For Your needs involving high durability and wear resistance, chromium plating is often the preferred choice due to its exceptional surface hardness and resistance to wear.

Applications in Industry

Nickel plating is widely used in the automotive and aerospace industries for corrosion resistance and enhanced wear properties, particularly in engine components and decorative trim. Chromium plating excels in hardening surfaces and improving aesthetic appeal, commonly applied in tools, machinery parts, and automotive bumpers for its high hardness and mirror-like finish. Both plating methods are critical in manufacturing for extending the lifespan and durability of metal products through tailored surface enhancements.

Environmental and Health Considerations

Nickel plating involves the use of hazardous chemicals like nickel salts and cyanide, posing risks of skin allergies and respiratory issues for workers, while generating toxic waste requiring careful disposal to prevent environmental contamination. Chromium plating, especially hexavalent chromium, is highly toxic and carcinogenic, necessitating stringent regulations and advanced filtration systems to protect both human health and ecosystems from exposure. You should weigh these environmental and health concerns alongside performance benefits when selecting between nickel and chromium plating for your projects.

Cost Comparison: Nickel vs Chromium Plating

Nickel plating generally offers a lower cost per unit compared to chromium plating due to cheaper raw materials and simpler processing requirements. Chromium plating involves higher expenses related to toxic chemical handling, hazardous waste disposal, and specialized equipment, driving up overall production costs. The cost differential makes nickel plating more economically favorable for large-scale applications requiring corrosion resistance and moderate wear protection.

Maintenance and Longevity

Nickel plating offers strong corrosion resistance and is easier to maintain due to its slightly softer surface, allowing for minor repairs without extensive rework. Chromium plating provides superior hardness and scratch resistance, giving longer-lasting protection against wear but often requires more careful maintenance to prevent cracking or peeling. Your choice depends on whether you prioritize ease of upkeep with decent longevity (nickel) or maximum durability with more stringent care (chromium).

Choosing the Right Plating for Your Needs

Nickel plating offers excellent corrosion resistance and a smooth, uniform finish ideal for decorative and functional purposes, while chromium plating provides superior hardness and a highly reflective surface perfect for wear resistance and aesthetic appeal. Evaluating factors such as environmental exposure, desired durability, and visual requirements helps determine whether nickel's affordability and versatility or chromium's toughness and shine better suit your project's needs. Selecting the right plating ensures optimal performance and longevity based on specific industrial or consumer applications.

Nickel plating vs chromium plating Infographic

libmatt.com

libmatt.com