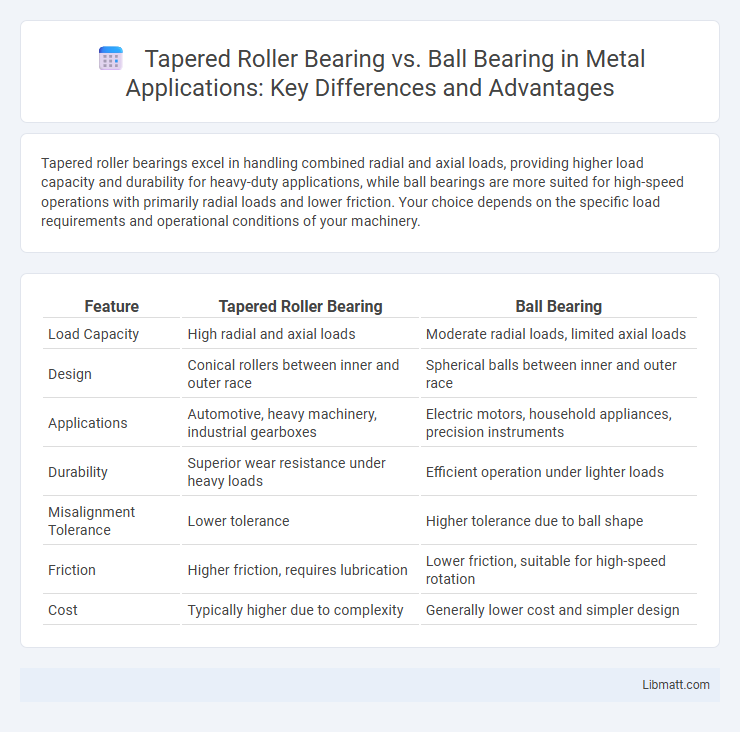

Tapered roller bearings excel in handling combined radial and axial loads, providing higher load capacity and durability for heavy-duty applications, while ball bearings are more suited for high-speed operations with primarily radial loads and lower friction. Your choice depends on the specific load requirements and operational conditions of your machinery.

Table of Comparison

| Feature | Tapered Roller Bearing | Ball Bearing |

|---|---|---|

| Load Capacity | High radial and axial loads | Moderate radial loads, limited axial loads |

| Design | Conical rollers between inner and outer race | Spherical balls between inner and outer race |

| Applications | Automotive, heavy machinery, industrial gearboxes | Electric motors, household appliances, precision instruments |

| Durability | Superior wear resistance under heavy loads | Efficient operation under lighter loads |

| Misalignment Tolerance | Lower tolerance | Higher tolerance due to ball shape |

| Friction | Higher friction, requires lubrication | Lower friction, suitable for high-speed rotation |

| Cost | Typically higher due to complexity | Generally lower cost and simpler design |

Introduction to Tapered Roller Bearing and Ball Bearing

Tapered roller bearings consist of tapered inner and outer ring raceways with tapered rollers positioned between them, designed to handle combined radial and axial loads efficiently. Ball bearings use spherical balls between inner and outer rings, optimized primarily for low-friction and high-speed radial load applications. Their distinct geometries influence load capacity, friction levels, and suitable use cases in mechanical systems.

Basic Design Differences

Tapered roller bearings feature conical rollers placed between inner and outer raceways, allowing them to handle both radial and axial loads efficiently, while ball bearings use spherical balls that primarily support radial loads with limited axial capacity. The angular contact design of tapered roller bearings distributes forces more evenly, making them ideal for heavy-duty applications requiring durability and precise alignment. Understanding these basic design differences helps you select the right bearing type for your machinery's load and performance needs.

Load Handling Capabilities

Tapered roller bearings offer superior load handling capabilities compared to ball bearings, excelling in both radial and axial load support due to their conical geometry. Ball bearings primarily handle radial loads and moderate axial loads but are less effective under heavy combined loads. Choosing tapered roller bearings ensures your machinery can withstand higher stress and maintain stability under demanding operational conditions.

Speed Limitations

Tapered roller bearings are designed to handle heavy radial and axial loads, but typically operate at lower maximum speeds compared to ball bearings due to increased friction from the line contact between rollers and raceways. Ball bearings, featuring point contact and reduced friction, support higher rotational speeds, making them suitable for applications requiring rapid motion. Speed limitations for tapered roller bearings often restrict them to moderate RPM ranges, whereas ball bearings can achieve significantly higher RPMs in precision machinery.

Friction and Efficiency Comparison

Tapered roller bearings exhibit higher friction than ball bearings due to their larger contact area, resulting in increased rolling resistance and slightly reduced efficiency. Ball bearings offer lower friction levels, enhancing efficiency in high-speed applications with lighter loads. Understanding these differences helps you choose the right bearing for optimal performance based on your friction and efficiency requirements.

Durability and Lifespan

Tapered roller bearings offer superior durability and lifespan compared to ball bearings due to their ability to handle higher radial and axial loads with reduced wear. Their design distributes stress over a larger surface area, resulting in enhanced resistance to deformation and longer service life under heavy-duty conditions. Choosing tapered roller bearings can extend your equipment's operational life, especially in applications involving harsh environments or heavy loads.

Common Applications for Each Type

Tapered roller bearings are commonly used in automotive wheel hubs, gearboxes, and heavy machinery due to their ability to handle combined radial and axial loads. Ball bearings are frequently found in electric motors, household appliances, and precision instruments where low friction and high-speed operation are essential. Both bearing types are selected based on load requirements and rotational speed, ensuring optimal performance in specific applications.

Maintenance and Lubrication Requirements

Tapered roller bearings require regular inspection and re-lubrication with high-quality grease or oil to maintain optimal performance under heavy radial and axial loads. Ball bearings, typically handling lighter loads, demand less frequent maintenance and can use grease or sealed-for-life lubrication, reducing downtime. Proper lubrication management extends the lifespan of both bearing types, ensuring Your machinery operates smoothly and efficiently.

Cost and Availability

Tapered roller bearings generally have a higher initial cost due to their complex design and manufacturing process but offer better load-carrying capacity, making them cost-effective for heavy-duty applications. Ball bearings, being simpler in construction, are more widely available and affordable, especially for low to moderate load uses. The choice between the two depends on balancing budget constraints with performance requirements, where ball bearings excel in cost efficiency and accessibility, while tapered roller bearings justify their price through durability and load handling.

Choosing the Right Bearing for Your Needs

Tapered roller bearings excel in handling combined axial and radial loads, making them ideal for heavy-duty applications such as automotive wheel hubs and industrial machinery. Ball bearings provide lower friction and higher-speed performance, suitable for lighter loads and precision devices like electric motors and household appliances. Selecting the right bearing depends on load type, speed requirements, and operating conditions to ensure optimal durability and efficiency.

Tapered Roller Bearing vs Ball Bearing Infographic

libmatt.com

libmatt.com