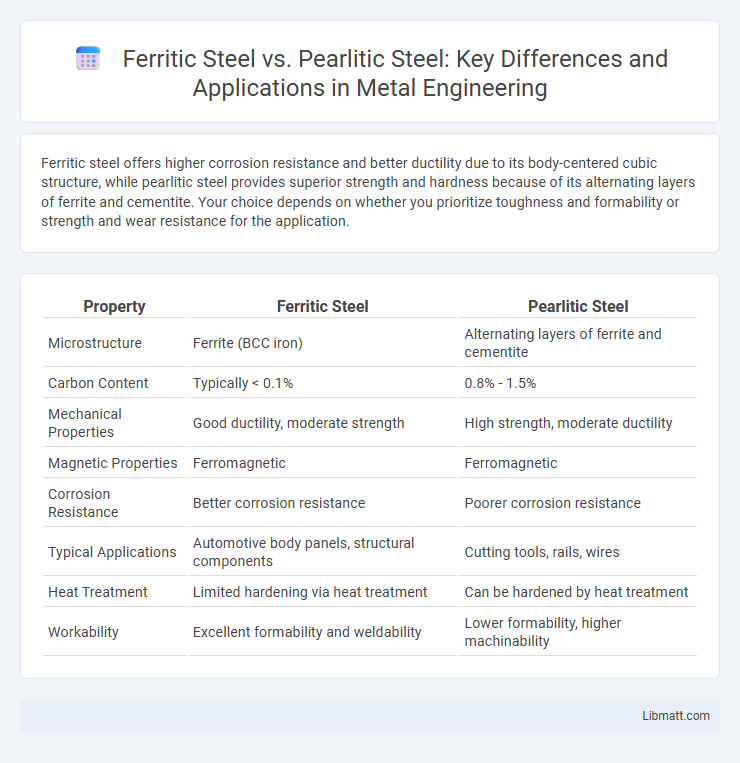

Ferritic steel offers higher corrosion resistance and better ductility due to its body-centered cubic structure, while pearlitic steel provides superior strength and hardness because of its alternating layers of ferrite and cementite. Your choice depends on whether you prioritize toughness and formability or strength and wear resistance for the application.

Table of Comparison

| Property | Ferritic Steel | Pearlitic Steel |

|---|---|---|

| Microstructure | Ferrite (BCC iron) | Alternating layers of ferrite and cementite |

| Carbon Content | Typically < 0.1% | 0.8% - 1.5% |

| Mechanical Properties | Good ductility, moderate strength | High strength, moderate ductility |

| Magnetic Properties | Ferromagnetic | Ferromagnetic |

| Corrosion Resistance | Better corrosion resistance | Poorer corrosion resistance |

| Typical Applications | Automotive body panels, structural components | Cutting tools, rails, wires |

| Heat Treatment | Limited hardening via heat treatment | Can be hardened by heat treatment |

| Workability | Excellent formability and weldability | Lower formability, higher machinability |

Introduction to Ferritic and Pearlitic Steel

Ferritic steel is primarily composed of iron with a body-centered cubic (BCC) crystal structure that provides excellent ductility and corrosion resistance, making it suitable for automotive and structural applications. Pearlitic steel contains alternating layers of ferrite and cementite, creating a lamellar structure that enhances hardness and tensile strength, commonly used in rails and cutting tools. Understanding the distinct microstructures of ferritic and pearlitic steel helps you select the optimal material for strength or formability requirements.

Chemical Composition Differences

Ferritic steel primarily consists of a higher percentage of iron with low carbon content, typically below 0.1%, and contains alloying elements such as chromium and manganese to enhance corrosion resistance and mechanical properties. Pearlites steel, in contrast, contains a higher carbon content ranging from 0.8% to 1.2%, leading to a microstructure composed of alternating layers of ferrite and cementite that provide greater hardness and strength. Understanding these chemical composition differences helps you select the appropriate steel type based on requirements for ductility, strength, or corrosion resistance in your applications.

Microstructure Comparison

Ferritic steel features a microstructure composed predominantly of ferrite, a body-centered cubic (BCC) iron phase characterized by its ductility and low carbon content, resulting in a softer and more corrosion-resistant material. Pearlite consists of a lamellar mixture of ferrite and cementite (iron carbide), providing higher strength and hardness due to the alternating layers that impede dislocation movement. The distinct microstructural differences between ferritic and pearlitic steels directly influence their mechanical properties, making ferritic steel ideal for applications requiring toughness and corrosion resistance, while pearlitic steel suits high-strength requirements.

Mechanical Properties

Ferritic steel exhibits lower tensile strength but higher ductility and toughness compared to pearlitic steel, making it suitable for applications requiring good formability and impact resistance. Pearlitic steel, characterized by alternating layers of ferrite and cementite, provides superior hardness, wear resistance, and tensile strength due to its lamellar microstructure. The choice between ferritic and pearlitic steel depends largely on the mechanical property requirements of the application, with ferritic steel favored for enhanced corrosion resistance and pearlitic steel ideal for demanding structural and wear-intensive environments.

Manufacturing Processes

Ferritic steel is produced through controlled cooling processes that promote a body-centered cubic (BCC) microstructure, resulting in lower carbon content and enhanced ductility. Pearlite steel manufacturing involves slower cooling rates that enable the formation of alternating layers of ferrite and cementite, providing higher strength and wear resistance. Your choice between ferritic and pearlitic steel depends on the required mechanical properties and the specific heat treatment techniques applied during production.

Corrosion Resistance

Ferritic steel offers superior corrosion resistance compared to pearlitic steel due to its higher chromium content and stable ferrite phase, which forms a protective oxide layer. Pearlitic steel, with its laminated structure of ferrite and cementite, tends to be less corrosion-resistant and more prone to rust in harsh environments. You can expect ferritic steel to perform better in applications requiring enhanced durability against oxidation and corrosive agents.

Applications in Industry

Ferritic steel is widely used in automotive exhaust systems, appliances, and construction due to its excellent corrosion resistance and good formability. Pearlitic steel is favored in the manufacture of railway tracks, cutting tools, and springs because of its high strength and wear resistance. Both steel types play critical roles in industrial applications requiring specific mechanical properties tailored to performance and durability.

Advantages of Ferritic Steel

Ferritic steel offers superior corrosion resistance due to its high chromium content, making it ideal for automotive exhaust systems and industrial applications. Its magnetic properties and good ductility provide easier fabrication and welding compared to pearlitic steel. Furthermore, ferritic steel exhibits better thermal conductivity and lower thermal expansion, enhancing its performance in high-temperature environments.

Benefits of Pearlitic Steel

Pearlitic steel offers superior wear resistance and high tensile strength due to its distinct lamellar microstructure composed of alternating ferrite and cementite layers. This makes pearlitic steel ideal for applications requiring durability, such as railway tracks, cutting tools, and springs. Your choice of pearlitic steel ensures enhanced performance in high-stress environments where abrasion resistance is crucial.

Choosing the Right Steel for Your Needs

Ferritic steel, known for its magnetic properties and excellent corrosion resistance, offers superior toughness and ductility compared to pearlitic steel, which excels in hardness and wear resistance due to its layered microstructure. Your choice depends on the application's demand for strength, machinability, and resistance to wear or corrosion. Selecting ferritic steel benefits projects requiring high thermal conductivity and formability, while pearlitic steel suits applications needing enhanced strength and abrasion resistance.

ferritic steel vs pearlitic steel Infographic

libmatt.com

libmatt.com