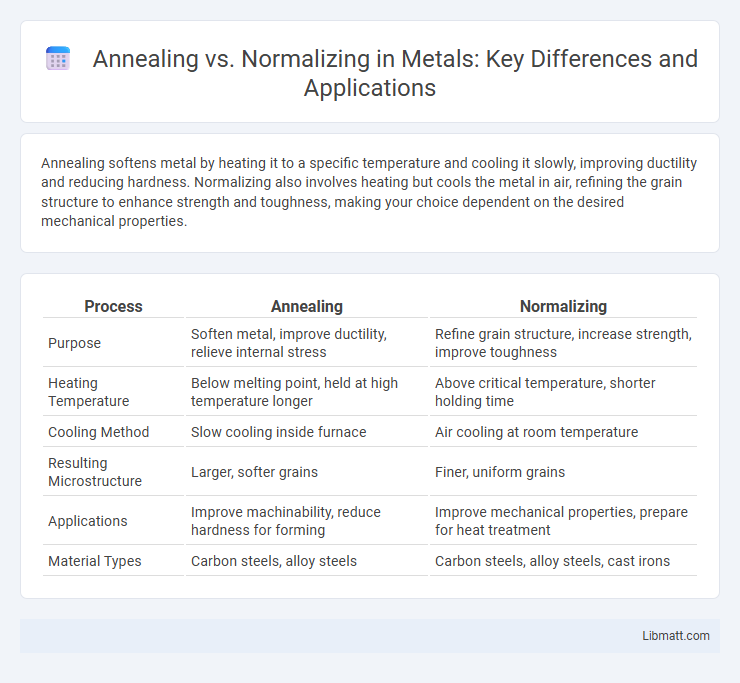

Annealing softens metal by heating it to a specific temperature and cooling it slowly, improving ductility and reducing hardness. Normalizing also involves heating but cools the metal in air, refining the grain structure to enhance strength and toughness, making your choice dependent on the desired mechanical properties.

Table of Comparison

| Process | Annealing | Normalizing |

|---|---|---|

| Purpose | Soften metal, improve ductility, relieve internal stress | Refine grain structure, increase strength, improve toughness |

| Heating Temperature | Below melting point, held at high temperature longer | Above critical temperature, shorter holding time |

| Cooling Method | Slow cooling inside furnace | Air cooling at room temperature |

| Resulting Microstructure | Larger, softer grains | Finer, uniform grains |

| Applications | Improve machinability, reduce hardness for forming | Improve mechanical properties, prepare for heat treatment |

| Material Types | Carbon steels, alloy steels | Carbon steels, alloy steels, cast irons |

Introduction to Annealing and Normalizing

Annealing and normalizing are heat treatment processes used to alter the microstructure and mechanical properties of metals. Annealing involves heating a material to a specific temperature and then cooling it slowly to reduce hardness and increase ductility, promoting grain growth and relieving internal stresses. Normalizing entails heating the material above its critical temperature followed by air cooling, resulting in a more uniform grain structure and improved mechanical properties such as strength and toughness.

Definition of Annealing

Annealing is a heat treatment process that involves heating a metal to a specific temperature and then cooling it slowly to remove internal stresses and improve ductility. This process refines the grain structure of the metal, making it softer and easier to work with. Your choice between annealing and normalizing depends on the desired mechanical properties and the type of steel you are treating.

Definition of Normalizing

Normalizing is a heat treatment process that involves heating a metal to a temperature above its critical range, followed by air cooling to refine its grain structure and improve mechanical properties. This process enhances uniformity in the microstructure, increases toughness, and relieves internal stresses caused by prior manufacturing processes. Normalizing is commonly applied to steel components to achieve improved machinability and strength consistency.

Key Differences Between Annealing and Normalizing

Annealing involves heating a metal to a specific temperature and then slowly cooling it to remove internal stresses and soften the material, enhancing ductility. Normalizing heats the metal to a higher temperature followed by air cooling, resulting in a more uniform and refined grain structure that improves strength and hardness. The key difference lies in cooling methods: annealing uses slow cooling typically in a furnace, while normalizing relies on faster air cooling, affecting the final mechanical properties of the metal.

Metallurgical Principles Behind Annealing

Annealing involves heating a metal to a specific temperature below its melting point and then cooling it slowly to relieve internal stresses and refine its microstructure, promoting ductility and reducing hardness. It allows recrystallization, wherein deformed grains are replaced by new, strain-free grains, restoring the material's original properties. This process contrasts with normalizing, which cools the metal in air to produce a more uniform grain size and improved mechanical properties through a faster cooling rate.

Metallurgical Principles Behind Normalizing

Normalizing involves heating steel to a temperature above its critical point followed by air cooling, which refines the grain structure and improves mechanical properties such as strength and toughness. This process achieves a more uniform and fine pearlitic microstructure by allowing austenite to transform at a slower, controlled rate compared to quenching. The metallurgical principle centers on recrystallization and phase transformation, reducing internal stresses and homogenizing the alloy's microstructure for improved machinability and wear resistance.

Process Steps: Annealing vs Normalizing

Annealing involves heating the material to a specific temperature below its melting point, holding it there to allow internal stresses to relax, followed by slow cooling usually in a furnace to promote a soft, ductile microstructure. Normalizing requires heating the steel to a temperature above the critical range, holding it briefly, then cooling it in still air for a faster, more uniform grain structure that enhances strength and toughness. You can choose annealing for improved machinability and ductility, while normalizing suits applications needing refined grain size and balanced mechanical properties.

Effects on Material Properties

Annealing softens metal by reducing hardness and increasing ductility through controlled heating and slow cooling, which relieves internal stresses and improves machinability. Normalizing refines grain structure and enhances uniformity by heating above the critical temperature followed by air cooling, resulting in increased tensile strength and toughness. Understanding these effects allows you to select the appropriate heat treatment for achieving desired mechanical properties in steel or other alloys.

Common Applications in Industry

Annealing is commonly applied in the steel industry to enhance ductility and reduce hardness, improving machinability for components like gears, shafts, and automotive parts. Normalizing finds frequent use in manufacturing structural steel and heavy machinery to refine grain structure and achieve uniform mechanical properties. Both heat treatment processes are essential in aerospace, tool manufacturing, and metal fabrication to optimize material performance.

Choosing the Right Heat Treatment Method

Choosing the right heat treatment method depends on your material's desired mechanical properties and application requirements. Annealing softens metals to improve ductility and reduce hardness, making it ideal for machining and forming processes, while normalizing refines grain structure to enhance strength and toughness for structural components. Consider factors such as cooling rate, material type, and service conditions to select between annealing and normalizing for optimal performance.

Annealing vs Normalizing Infographic

libmatt.com

libmatt.com