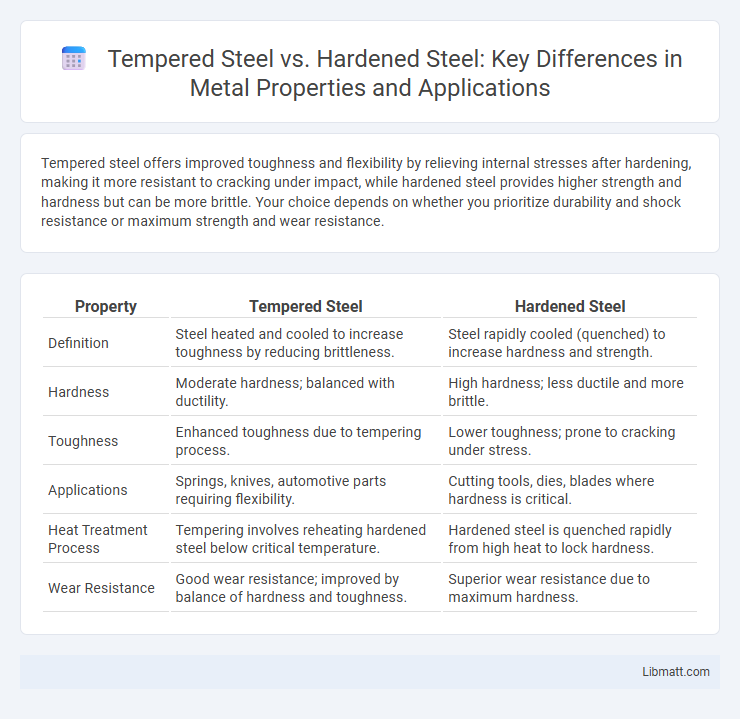

Tempered steel offers improved toughness and flexibility by relieving internal stresses after hardening, making it more resistant to cracking under impact, while hardened steel provides higher strength and hardness but can be more brittle. Your choice depends on whether you prioritize durability and shock resistance or maximum strength and wear resistance.

Table of Comparison

| Property | Tempered Steel | Hardened Steel |

|---|---|---|

| Definition | Steel heated and cooled to increase toughness by reducing brittleness. | Steel rapidly cooled (quenched) to increase hardness and strength. |

| Hardness | Moderate hardness; balanced with ductility. | High hardness; less ductile and more brittle. |

| Toughness | Enhanced toughness due to tempering process. | Lower toughness; prone to cracking under stress. |

| Applications | Springs, knives, automotive parts requiring flexibility. | Cutting tools, dies, blades where hardness is critical. |

| Heat Treatment Process | Tempering involves reheating hardened steel below critical temperature. | Hardened steel is quenched rapidly from high heat to lock hardness. |

| Wear Resistance | Good wear resistance; improved by balance of hardness and toughness. | Superior wear resistance due to maximum hardness. |

Introduction to Tempered and Hardened Steel

Tempered steel undergoes a heat treatment process that improves its toughness and ductility while reducing brittleness, making it ideal for tools and blades requiring flexibility and wear resistance. Hardened steel, achieved through quenching, increases hardness and strength but can become brittle without further tempering. Understanding the differences in these heat treatments helps you select the best material for high-performance applications demanding specific mechanical properties.

Defining Tempered Steel

Tempered steel is a type of alloy steel that undergoes a heat treatment process involving heating to a specific temperature below its critical point, followed by controlled cooling, which enhances its toughness and reduces brittleness. This treatment balances hardness and ductility, making tempered steel ideal for applications requiring resistance to impact and fatigue, such as automotive components and cutting tools. Compared to hardened steel, which is primarily focused on maximizing hardness through rapid cooling, tempered steel offers improved structural integrity and flexibility.

Understanding Hardened Steel

Hardened steel undergoes a heat treatment process called quenching, which rapidly cools the metal to increase its hardness and strength by transforming its microstructure into martensite. This process significantly enhances wear resistance and durability, making hardened steel ideal for cutting tools, bearings, and high-stress mechanical components. Unlike tempered steel, which is reheated after hardening to reduce brittleness, hardened steel remains in a more brittle yet harder state, offering superior resistance to deformation under heavy loads.

Key Differences Between Tempered and Hardened Steel

Tempered steel undergoes a controlled heat treatment process that balances hardness and toughness by reducing brittleness, whereas hardened steel is heated and quenched rapidly to maximize hardness at the expense of ductility. Tempered steel typically offers improved impact resistance and flexibility, making it suitable for tools and structural components that require durability under stress; hardened steel is preferred for applications demanding maximum wear resistance and edge retention, such as cutting instruments. The key differences lie in their heat treatment methods, mechanical properties, and optimal usage scenarios dictated by hardness, toughness, and brittleness levels.

Manufacturing Processes Compared

Tempered steel undergoes a controlled heat treatment process where the steel is first heated to a high temperature and then rapidly cooled, followed by reheating to a lower temperature to improve toughness and reduce brittleness. Hardened steel is primarily produced through quenching, involving heating steel to its critical temperature and quickly cooling it to form a hard and wear-resistant microstructure called martensite. While tempering adjusts the balance between hardness and ductility post-quenching, hardening focuses on maximizing hardness and strength through rapid cooling.

Mechanical Properties: Strength and Toughness

Tempered steel offers an ideal balance between strength and toughness due to its heat treatment process, which reduces brittleness while maintaining high tensile strength. Hardened steel exhibits superior hardness and wear resistance but tends to be more brittle, making it less impact-resistant compared to tempered steel. Your choice between tempered and hardened steel depends on whether you prioritize toughness for shock absorption or maximum strength for durability.

Common Applications of Tempered Steel

Tempered steel is widely used in automotive components, such as gears, crankshafts, and suspension springs, due to its enhanced toughness and flexibility. It is also common in manufacturing cutting tools and blades, where resistance to impact and wear is critical. Structural parts in machinery and construction benefit from tempered steel's improved strength and reduced brittleness.

Typical Uses for Hardened Steel

Hardened steel is commonly used in cutting tools, such as knives, drills, and saw blades, due to its high wear resistance and ability to retain sharp edges. It is also widely employed in the manufacturing of industrial machinery components, including gears, bearings, and shafts, where strength and durability under stress are critical. Additionally, hardened steel is favored in automotive and aerospace applications for parts requiring enhanced toughness and improved fatigue resistance.

Pros and Cons of Tempered vs Hardened Steel

Tempered steel offers increased toughness and flexibility, reducing brittleness compared to hardened steel, which provides superior hardness and wear resistance but is more prone to cracking under impact. The tempering process balances strength and ductility by reheating hardened steel, making tempered steel ideal for applications requiring shock absorption and durability. Hardened steel excels in cutting tools and wear-prone parts due to its high hardness but requires careful handling to avoid fractures, while tempered steel suits structural components needing resilience and toughness.

Choosing the Right Steel for Your Project

Tempered steel offers improved toughness and flexibility by balancing hardness and ductility, making it ideal for projects requiring impact resistance and durability. Hardened steel provides maximum strength and wear resistance due to its increased hardness but can be more brittle, suiting applications where surface hardness is critical. Choosing the right steel depends on your project's specific needs for strength, flexibility, and durability to ensure optimal performance and longevity.

Tempered steel vs hardened steel Infographic

libmatt.com

libmatt.com