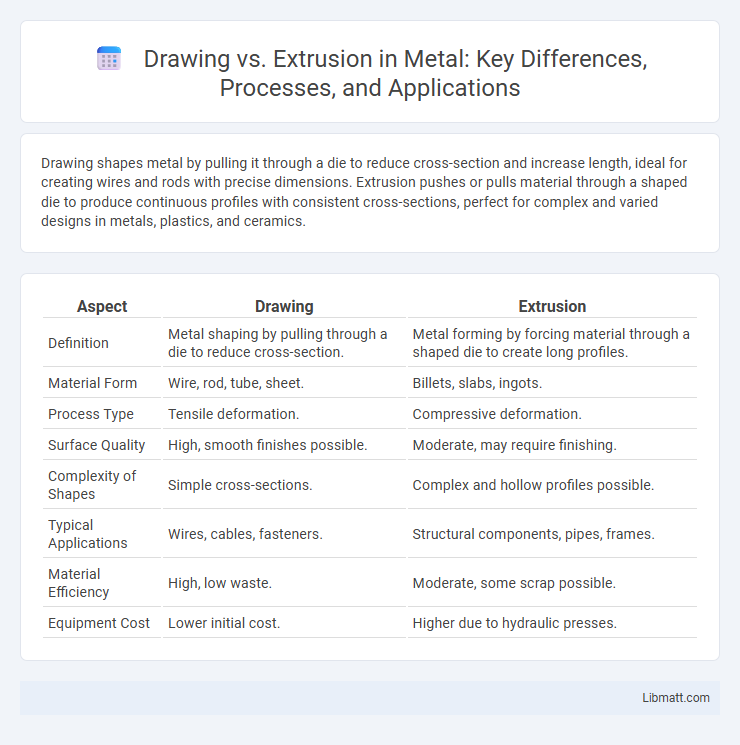

Drawing shapes metal by pulling it through a die to reduce cross-section and increase length, ideal for creating wires and rods with precise dimensions. Extrusion pushes or pulls material through a shaped die to produce continuous profiles with consistent cross-sections, perfect for complex and varied designs in metals, plastics, and ceramics.

Table of Comparison

| Aspect | Drawing | Extrusion |

|---|---|---|

| Definition | Metal shaping by pulling through a die to reduce cross-section. | Metal forming by forcing material through a shaped die to create long profiles. |

| Material Form | Wire, rod, tube, sheet. | Billets, slabs, ingots. |

| Process Type | Tensile deformation. | Compressive deformation. |

| Surface Quality | High, smooth finishes possible. | Moderate, may require finishing. |

| Complexity of Shapes | Simple cross-sections. | Complex and hollow profiles possible. |

| Typical Applications | Wires, cables, fasteners. | Structural components, pipes, frames. |

| Material Efficiency | High, low waste. | Moderate, some scrap possible. |

| Equipment Cost | Lower initial cost. | Higher due to hydraulic presses. |

Introduction to Drawing and Extrusion

Drawing and extrusion are fundamental metalworking processes used to shape materials with precision. Drawing involves pulling a metal through a die to reduce its diameter and increase length, commonly used in wire and tube production, while extrusion forces material through a shaped die to create complex cross-sectional profiles, widely applied in manufacturing pipes, rods, and structural components. Both techniques optimize material properties and dimensional accuracy for various industrial applications.

Defining Drawing: Processes and Techniques

Drawing refers to a metalworking process that shapes material by pulling it through a die to reduce its diameter and increase length, enhancing its mechanical properties. Techniques include wire drawing, sheet metal drawing, and tube drawing, each tailored to specific requirements such as thickness control and surface finish. You can achieve precise dimensions and improved strength through controlled deformation without adding material.

Understanding Extrusion: Methods and Applications

Extrusion is a manufacturing process where material is pushed or drawn through a die to create objects with a fixed cross-sectional profile, commonly used for metals, plastics, and ceramics. Methods include direct extrusion, indirect extrusion, and hydrostatic extrusion, each suited for different materials and product requirements. Understanding extrusion helps you select the right technique for applications such as creating pipes, rods, and complex profiles with improved structural integrity and surface finish.

Key Differences Between Drawing and Extrusion

Drawing involves pulling a metal through a die to reduce its cross-sectional area, producing wire, rods, or tubes with improved surface finish and mechanical properties. Extrusion forces material through a die by compressive force, creating complex cross-sectional shapes that may be solid or hollow, ideal for aluminum profiles or plastic parts. Your choice depends on the desired shape, material flow characteristics, and mechanical requirements of the final product.

Materials Suitable for Drawing vs Extrusion

Drawing is ideal for ductile metals such as copper, aluminum, and steel, which can withstand tensile stress without fracturing. Extrusion suits a wider range of materials including metals like aluminum and copper, as well as plastics and ceramics, due to its capability to shape materials under compressive forces. The choice between drawing and extrusion depends on the material's ductility and the desired final product shape.

Advantages of Drawing in Manufacturing

Drawing in manufacturing offers superior dimensional accuracy and enhanced surface finish compared to extrusion. This process allows for precise control over complex cross-sectional shapes, ideal for producing wires, tubes, and intricate profiles. You benefit from improved mechanical properties due to strain hardening during drawing, resulting in stronger and more durable components.

Benefits of Extrusion in Industry

Extrusion offers significant benefits in industry, including the ability to create complex cross-sectional profiles with consistent dimensions, reducing material waste and production time. This process supports high-volume manufacturing with excellent surface finish and mechanical properties, enhancing product durability and performance. Its versatility in handling various materials like metals, polymers, and ceramics makes extrusion essential for applications ranging from automotive parts to construction materials.

Common Applications of Drawing and Extrusion

Drawing is commonly used for manufacturing wire, cables, and thin metal sheets due to its ability to precisely reduce cross-sectional area while enhancing tensile strength. Extrusion finds extensive application in producing aluminum window frames, plastic pipes, and complex profiles, allowing for continuous shapes with consistent cross-sections. Your choice between drawing and extrusion depends on the desired product geometry and material properties.

Challenges and Limitations of Each Process

Drawing faces challenges such as material thinning and increased risk of cracks, limiting its use with brittle metals and complex shapes. Extrusion encounters limitations like high initial tooling costs and difficulty in producing intricate cross-sections, restricting design flexibility. Your choice between drawing and extrusion should consider these constraints to ensure optimal manufacturing outcomes.

Choosing Between Drawing and Extrusion for Optimal Results

Choosing between drawing and extrusion depends on your specific project requirements, such as the desired shape complexity and material characteristics. Drawing is ideal for creating precise, slender, and detailed metal parts, while extrusion excels at producing continuous profiles with uniform cross-sections. Understanding these differences ensures you select the method that delivers optimal efficiency, strength, and dimensional accuracy for your application.

Drawing vs Extrusion Infographic

libmatt.com

libmatt.com