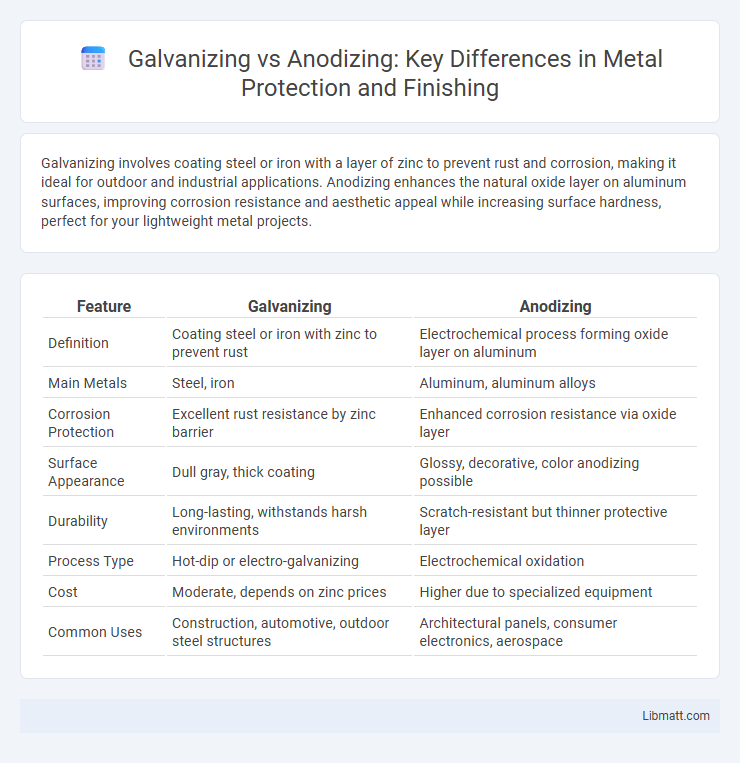

Galvanizing involves coating steel or iron with a layer of zinc to prevent rust and corrosion, making it ideal for outdoor and industrial applications. Anodizing enhances the natural oxide layer on aluminum surfaces, improving corrosion resistance and aesthetic appeal while increasing surface hardness, perfect for your lightweight metal projects.

Table of Comparison

| Feature | Galvanizing | Anodizing |

|---|---|---|

| Definition | Coating steel or iron with zinc to prevent rust | Electrochemical process forming oxide layer on aluminum |

| Main Metals | Steel, iron | Aluminum, aluminum alloys |

| Corrosion Protection | Excellent rust resistance by zinc barrier | Enhanced corrosion resistance via oxide layer |

| Surface Appearance | Dull gray, thick coating | Glossy, decorative, color anodizing possible |

| Durability | Long-lasting, withstands harsh environments | Scratch-resistant but thinner protective layer |

| Process Type | Hot-dip or electro-galvanizing | Electrochemical oxidation |

| Cost | Moderate, depends on zinc prices | Higher due to specialized equipment |

| Common Uses | Construction, automotive, outdoor steel structures | Architectural panels, consumer electronics, aerospace |

Introduction to Surface Protection Methods

Galvanizing and anodizing are essential surface protection methods designed to enhance metal durability and prevent corrosion. Galvanizing involves applying a protective zinc coating to steel or iron, providing a strong barrier against environmental damage, while anodizing is an electrochemical process that thickens the natural oxide layer on aluminum, improving corrosion resistance and aesthetic appeal. Understanding these methods helps you choose the best protection for your metal components based on material type and environmental exposure.

What is Galvanizing?

Galvanizing is a metal coating process that involves applying a protective layer of zinc to steel or iron to prevent corrosion and rust. This technique enhances the durability and longevity of metal structures, especially in outdoor or harsh environments. Zinc acts as a sacrificial anode, protecting the underlying metal by corroding first before the base material is affected.

What is Anodizing?

Anodizing is an electrochemical process that enhances the natural oxide layer on aluminum surfaces, increasing corrosion resistance and surface hardness. This treatment creates a durable, porous layer ideal for dye absorption and improved aesthetic appeal. Unlike galvanizing, which applies a protective zinc coating to steel, anodizing modifies the aluminum substrate itself for long-lasting protection.

Key Differences Between Galvanizing and Anodizing

Galvanizing involves coating steel or iron with a layer of zinc to prevent corrosion, while anodizing is an electrochemical process that enhances the natural oxide layer on aluminum surfaces for increased durability and aesthetic appeal. Galvanizing primarily protects ferrous metals from rust through sacrificial zinc coating, whereas anodizing improves aluminum's resistance to wear, corrosion, and provides color options. The key difference lies in their application methods and materials treated: galvanizing targets steel and iron, and anodizing is exclusive to aluminum and its alloys.

Materials Suitable for Galvanizing vs Anodizing

Galvanizing is primarily suitable for ferrous metals such as steel and iron, providing a protective zinc coating that prevents rust and corrosion. Anodizing is typically applied to non-ferrous metals, especially aluminum, enhancing corrosion resistance and surface hardness through an electrochemical process. While galvanizing adds a metallic layer, anodizing modifies the metal's surface oxide layer, making it ideal for lightweight materials requiring durability and aesthetic finishes.

Process Overview: Galvanizing Step-by-Step

Galvanizing involves coating steel or iron with a layer of zinc to protect against corrosion, typically through a hot-dip process where the metal is immersed in molten zinc at around 450degC. The process begins with surface preparation, including cleaning, pickling, and fluxing to remove impurities, ensuring optimal zinc adhesion. You benefit from enhanced corrosion resistance and extended metal lifespan due to this durable, sacrificial zinc coating.

Process Overview: Anodizing Step-by-Step

Anodizing involves immersing aluminum in an acid electrolyte bath and passing an electric current to create a durable oxide layer on the surface, enhancing corrosion resistance and aesthetic appeal. The step-by-step process includes cleaning the metal, rinsing, electrolytic anodizing, sealing, and final drying. You benefit from improved surface hardness and color options, making anodizing ideal for architectural and automotive applications.

Durability and Corrosion Resistance Comparison

Galvanizing involves coating steel or iron with a layer of zinc, offering robust corrosion resistance by sacrificially protecting the metal substrate, making it highly durable in outdoor and industrial environments. Anodizing enhances the natural oxide layer on aluminum surfaces, significantly increasing resistance to corrosion and wear, but it is primarily limited to aluminum and offers less protection against physical damage compared to galvanizing. Both processes improve longevity, with galvanizing excelling on ferrous metals through sacrificial protection and anodizing providing a hard, corrosion-resistant finish specifically for aluminum alloys.

Cost Implications of Galvanizing and Anodizing

Galvanizing generally incurs lower initial costs due to its simpler and faster application process, making it cost-effective for protecting steel structures against corrosion. Anodizing, while typically more expensive upfront because of the specialized equipment and energy required, offers enhanced durability and aesthetic appeal for aluminum surfaces, potentially reducing maintenance expenses over time. Understanding your project's material requirements and lifespan goals helps determine which method provides the best value for your investment.

Choosing the Right Method for Your Application

Galvanizing provides a robust, corrosion-resistant zinc coating suitable for outdoor and industrial metal structures, while anodizing enhances aluminum's natural oxide layer for improved durability and aesthetic appeal in architectural or electronic components. Your choice depends on the metal type and environmental exposure; galvanized steel excels in heavy-duty protection, whereas anodized aluminum offers scratch resistance and a variety of color finishes. Selecting the right method ensures optimal performance and longevity tailored to your specific application requirements.

Galvanizing vs Anodizing Infographic

libmatt.com

libmatt.com